RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM

Page 30

VOLUMIZER

®

TRANSMITTER

REPLACEMENT - SLIDE STOP

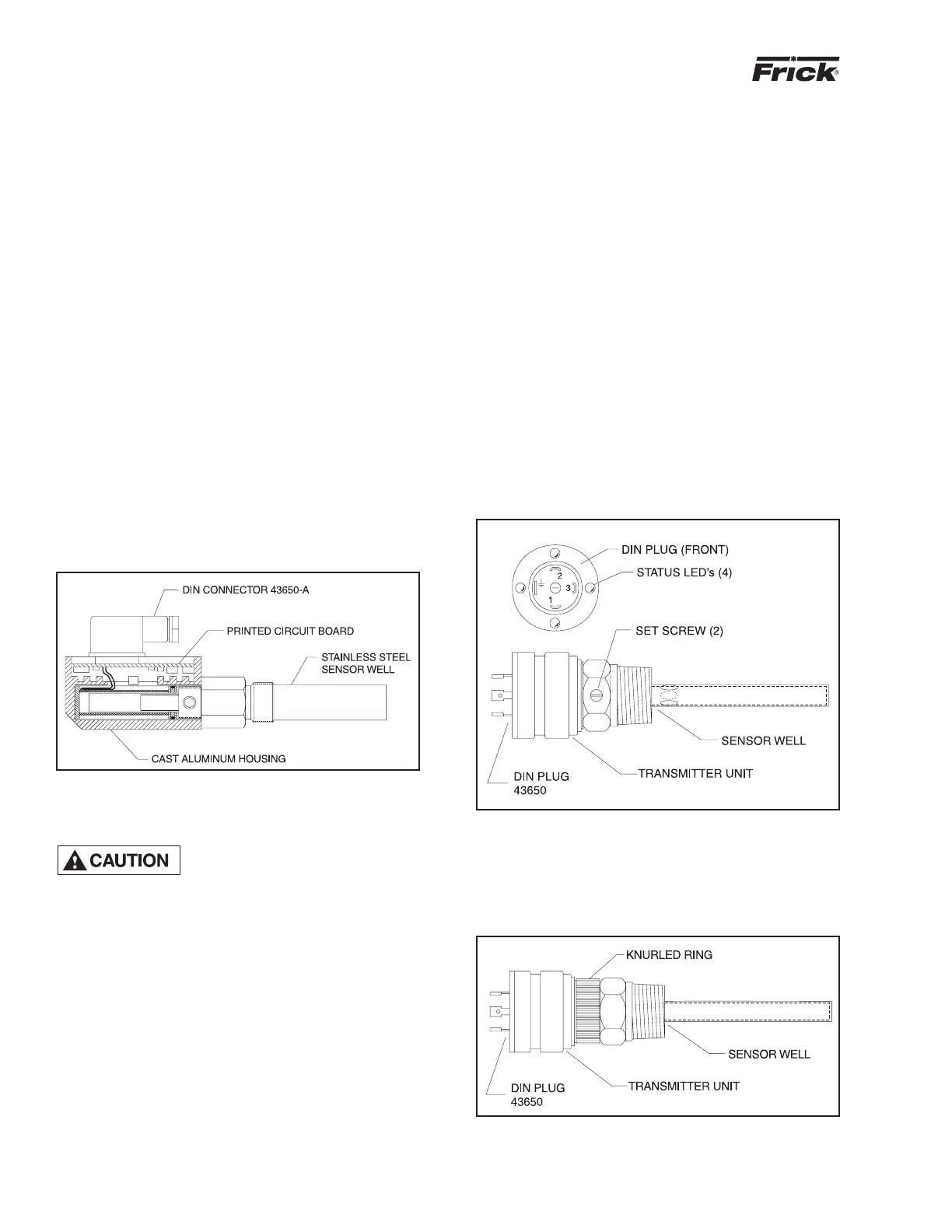

The VOLUMIZER

®

Transmitter is located on the right side of

the compressor (facing shaft) at the inlet end (see Figure 25).

The linear transmitter with hermetic enclosure is based on

the inductive measuring principle. It features removable elec-

tronics (from the sensor well) eliminating the need to evacu-

ate the compressor for replacement. This type of transmitter

is dedicated to volume ratio control and has no user adjust-

ments.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen set screws.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten set screws.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

NOTE: For calibration of the Volumizer

®

unit, refer to the

Analog Calibration instructions in publication S90-010 O.

Figure 25 - VOLUMIZER

®

TRANSMITTER

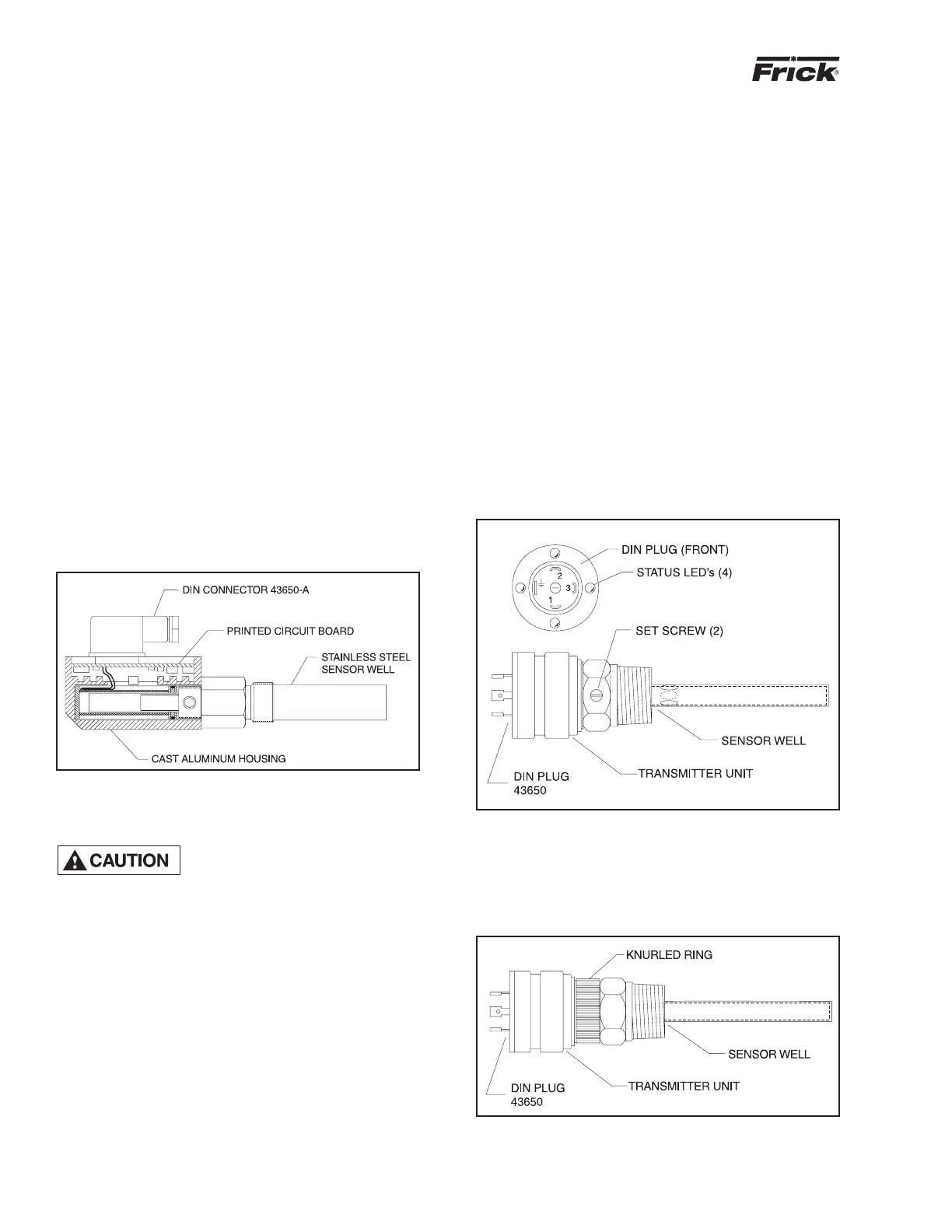

TEMPERATURE SENSOR REPLACEMENT

This device is static sensitive.

Please follow proper ESD proce-

dures when handling.

1. Shut off control power.

2. Remove DIN connector plug from transmitter (See Figure

27).

3. Unscrew knurled ring and remove transmitter unit.

4. Apply thermal compound to new sensor assembly, insert

into thermal well, and tighten knurled ring.

5. Apply DIN connector plug to transmitter.

6. Turn on control power.

NOTE: The temperature sensor is factory set. If calibra-

tion is required, refer to Analog Calibration instructions

in publication S90-010 O.

OIL LEVEL TRANSMITTER

REPLACEMENT

The Oil Level Transmitter is located on the front of the sepa-

rator near the bottom/center (see Figure 26).

The linear transmitter with hermetic enclosure is based on

the capacitive measuring principle. It features removable

electronics (from the sensor well) eliminating the need to

evacuate the compressor for replacement. This transmitter

is dedicated to oil level control and has no user adjustments.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen set screws.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten set screws.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

Figure 26 - OIL LEVEL TRANSMITTER

Figure 27 - TEMPERATURE TRANSMITTER

Loading...

Loading...