RWF ROTARY SCREW COMPRESSOR UNITS

PROPER INSTALLATION OF ELECTRONIC EQUIPMENT

S70-600 IOM

Page 44

PROPER INSTALLATION OF ELECTRONIC EQUIPMENT

IN AN INDUSTRIAL ENVIRONMENT

In today’s refrigeration plants, electronic controls have found

their way into almost every aspect of refrigeration control.

Electronic controls have brought to the industry more pre-

cise control, improved energy savings and operator conve-

niences. Electronic control devices have revolutionized the

way refrigeration plants operate today.

The earlier relay systems were virtually immune to radio fre-

quency interference (RFI), electromagnetic interference

(EMI), and ground loop currents. Therefore installation and

wiring were of little consequence and the wiring job con-

sisted of hooking up the point-to-point wiring and sizing the

wire properly. In an electronic system, improper installation

will cause problems that outweigh the benefits of electronic

control. Electronic equipment is susceptible to RFI, EMI, and

ground loop currents which can cause equipment shutdowns,

processor memory and program loss, erratic behavior, and

false readings. Manufacturers of industrial electronic equip-

ment take into consideration the effects of RFI, EMI, and

ground loop currents and incorporate protection of the elec-

tronics in their designs. These manufacturers require that

certain installation precautions be taken to protect the elec-

tronics from these effects. All electronic equipment must be

viewed as sensitive instrumentation and therefore requires

careful attention to installation procedures. These procedures

are well known to instrument engineers, but are usually not

followed by general electricians.

There are a few basics, that if followed, will result in a trouble-

free installation. The National Electric Code (NEC) is a guide-

line for safe wiring practices, but it does not deal with proce-

dures used for electronic control installation. Use the fol-

lowing procedures for electronic equipment installation.

These procedures do not override any rules by the NEC, but

are to be used in conjunction with the NEC code.

WIRE SIZING

Size supply wires one size larger than required for am-

perage draw to reduce instantaneous voltage dips

caused by large loads such as heaters and contactors

and solenoids. These sudden dips in voltage can cause

the processor, whether it be a microprocessor, a computer,

or a PLC to malfunction momentarily or cause a complete

reset of the control system. If the wire is loaded to its maxi-

mum capacity, the voltage dips are much larger, and the

potential of a malfunction is very high. If the wire is sized

one size larger than required, the voltage dips are smaller

than in a fully loaded supply wire, and the potential for mal-

function is much lower. The NEC code book calls for specific

wire sizes to be used based on current draw. An example of

this would be to use #14 gauge wire for circuits up to 15

amp or #12 gauge wire for circuits of up to 20 amp. There-

fore, when connecting the power feed circuit to an electronic

industrial control, use #12 gauge wire for a maximum cur-

rent draw of 15 amp and #10 wire for a maximum current

draw of 20 amp. Use this rule of thumb to minimize voltage

dips at the electronic control.

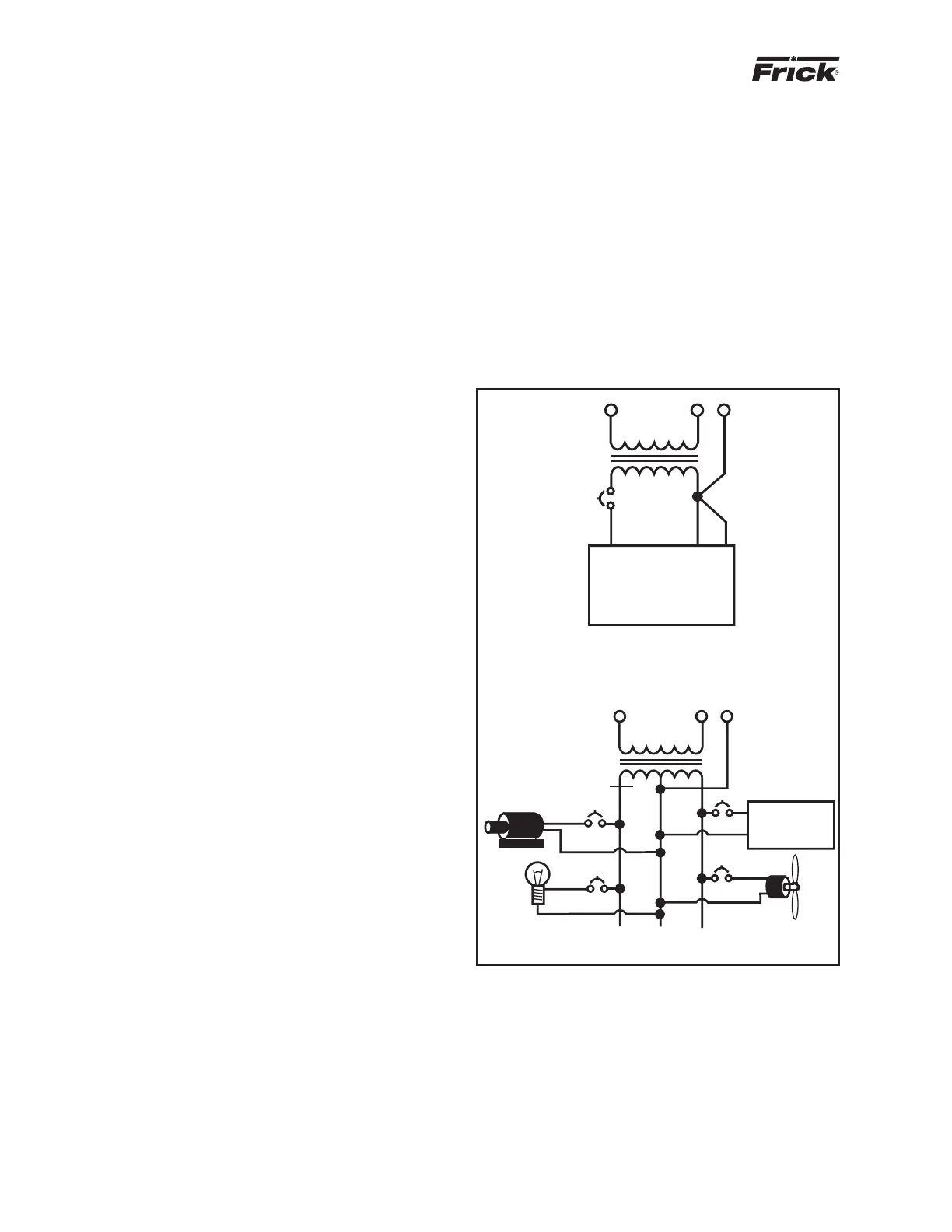

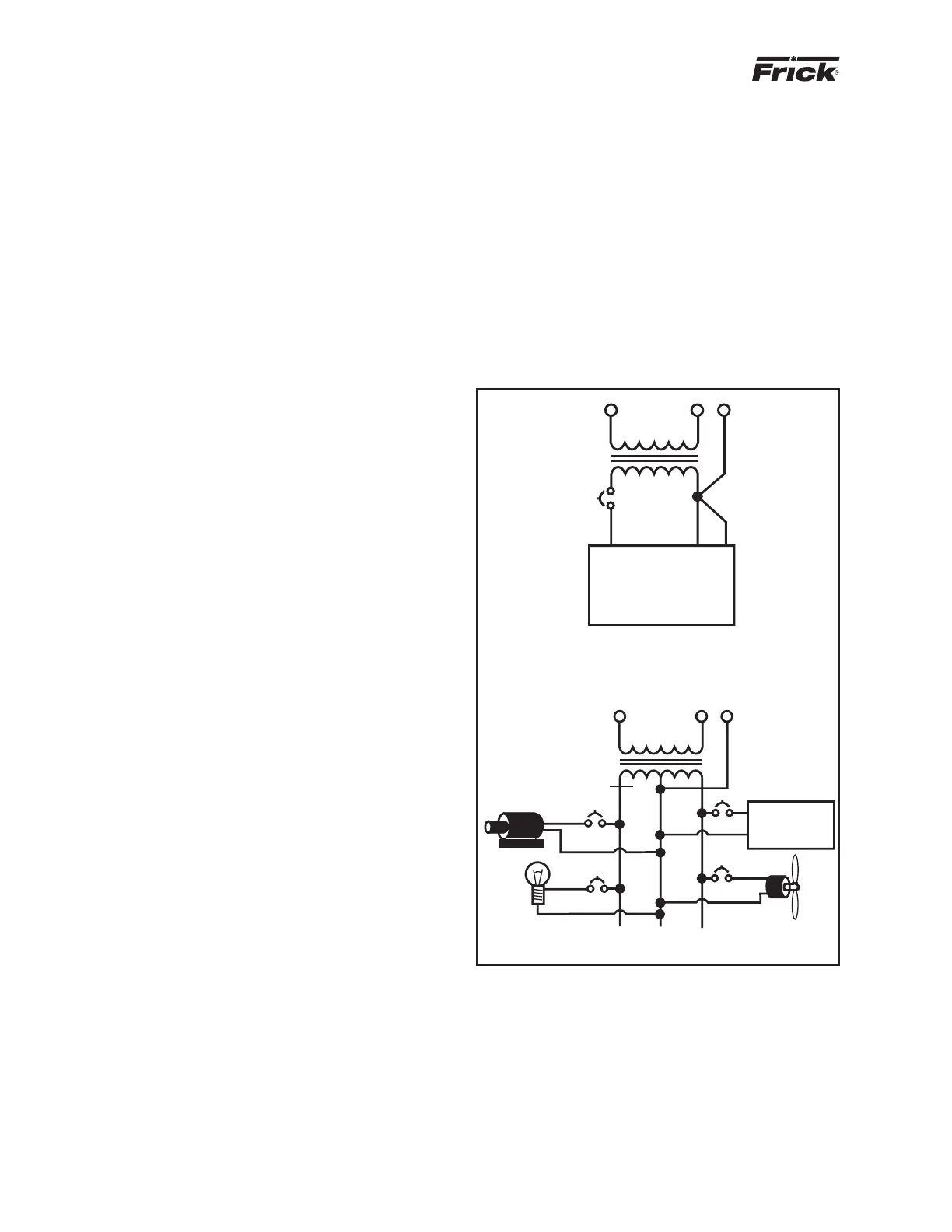

VOLTAGE SOURCE

Selecting the voltage source is extremely important for proper

operation of electronic equipment in an industrial environ-

ment. Standard procedure for electronic instrumentation is

to provide a “clean” separate source voltage in order to

prevent EMI, from other equipment in the plant, from inter-

fering with the operation of the electronic equipment. Con-

necting electronic equipment to a breaker panel (also known

as lighting panels and fuse panels) subjects the electronic

equipment to noise generated by other devices connected

to the breaker panel. This noise is known as electromag-

netic interference (EMI). EMI flows on the wires that are

common to a circuit. EMI cannot travel easily through trans-

formers and therefore can be isolated from selected circuits.

Use a control transformer to isolate the electronic con-

trol panel from other equipment in the plant that gener-

ate EMI. (Figure 1)

CONTROL

TRANSFORMER

ISOLATED

CIRCUIT

GROUND

ELECTRONIC CONTROL

CORRECT

ART1T

CONTROL

TRANSFORMER

NONISOLATED

CIRCUIT

GROUND

ELECTRONIC

CONTROL

INCORRECT

ART1B

Figure 1

Loading...

Loading...