RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM

Page 26

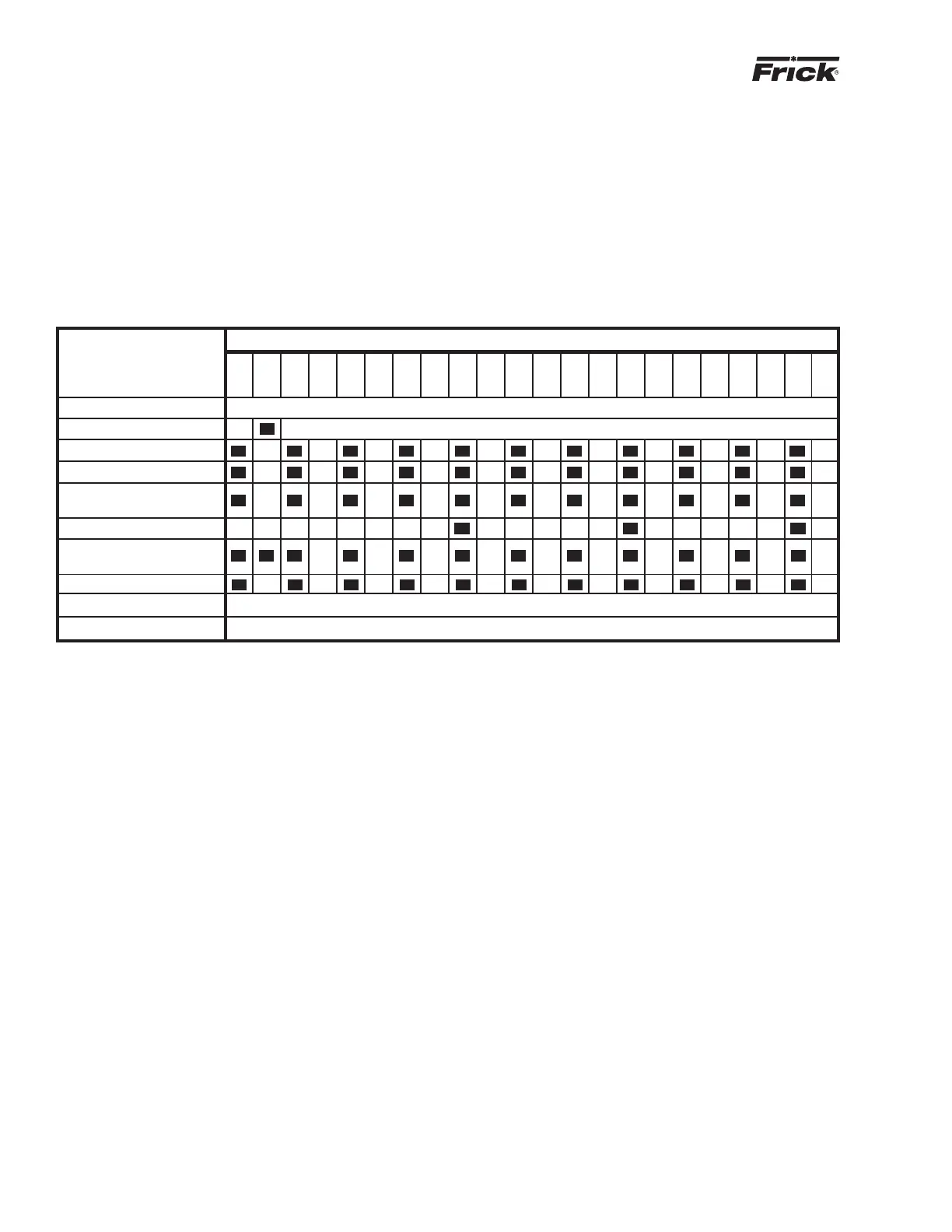

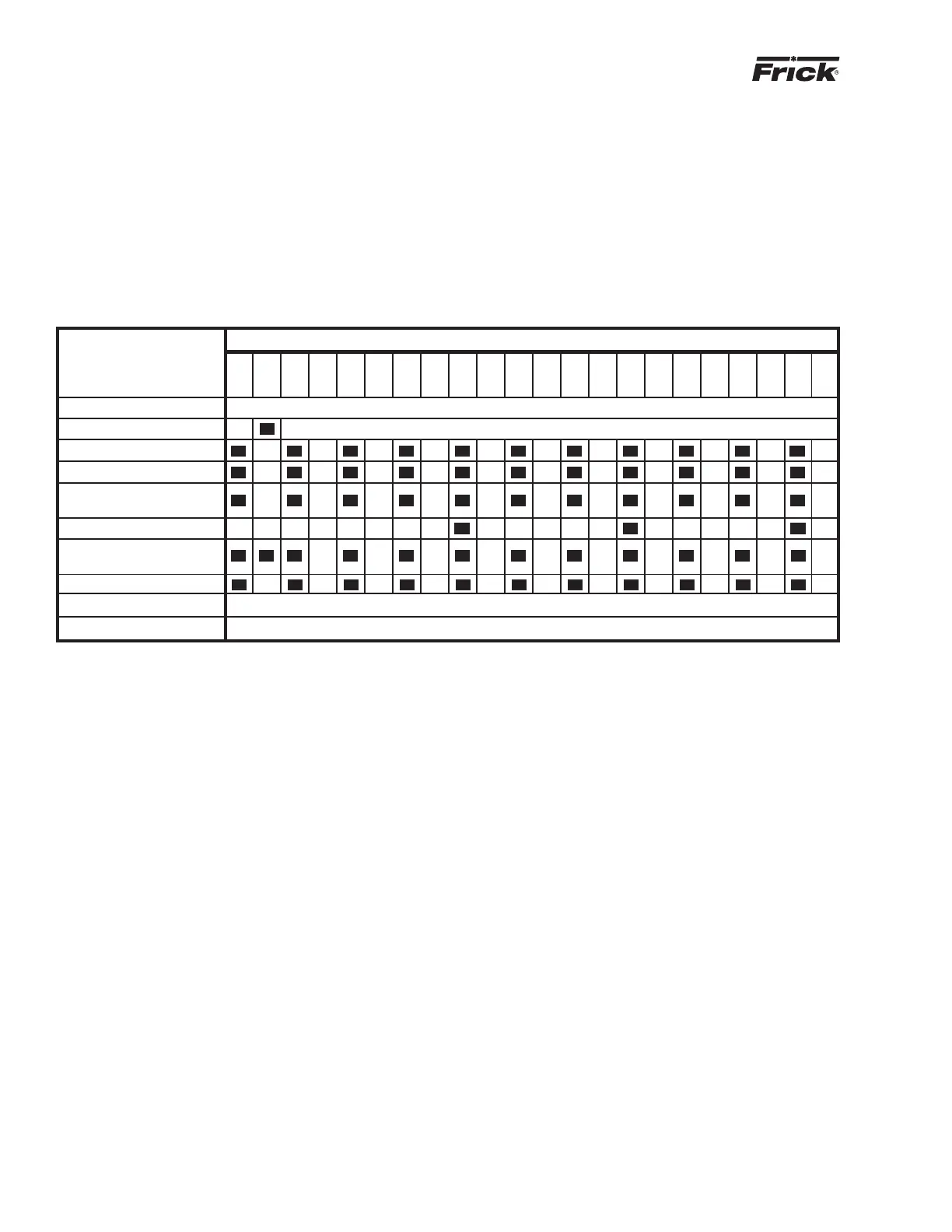

MAINTENANCE SCHEDULE

OPERATING LOG

The use of an operating log as included in this manual (see Table of Contents) permits thorough analysis of the operation of a

refrigeration system by those responsible for its maintenance and servicing. Continual recording of gauge pressures, tempera-

tures, and other pertinent information, enables the observer and serviceman to be constantly familiar with the operation of the

system and to recognize immediately any deviations from normal operating conditions. It is recommended that readings be taken

at least every four hours.

This schedule should be followed to ensure trouble-free operation of the compressor unit.

CLEAN OIL STRAINERS

CLEAN LIQUID

STRAINERS

REPLACE FILTER

REPLACE COALESCER

CHECK AND CLEAN

SUCTION STRAINER

95000

90000

85000

80000

75000

70000

65000

60000

55000

50000

45000

40000

35000

30000

25000

20000

15000

10000

8000

5000

1000

200

MAINTENANCE

FREQUENCY OR HOURS OF OPERATION (MAXIMUM)

CHANGE OIL As directed by oil analysis

OIL ANALYSIS Then every 6 months

VIBRATION ANALYSIS Every 6 months, more frequently if levels increase

REPLACE SEAL When leak rate exceeds 7 - 8 drops per minute

CHECK COUPLING

Loading...

Loading...