070-450 IOM (NOV 13)

Page 14

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

HOLDING CHARGE AND STORAGE

Every XJF compressor is pressure and leak tested at the

Johnson Controls–Frick factory and then thoroughly evacu-

ated and charged with dry nitrogen to ensure its integrity

during shipping and short term storage prior to installation.

All compressors must be kept in a clean, dry location to

prevent corrosion damage. Compressors that will be stored

for more than two months must have their nitrogen charge

checked periodically (see pages in GENERAL INFORMATION

for complete instructions).

WARNING

Holding-charge shipping gauges (if mounted) are rated

for 30 psig and are for checking the shipping charge

only. They must be removed before pressure testing

and operating the system. Failure to remove these

gauges may result in catastrophic failure of the gauge

resulting in serious injury or death.

Access valves are bronze and they must be replaced with

steel plugs when package is assembled.

WARNING

THIS EQUIPMENT HAS BEEN PRESSURIZED WITH

NITROGEN GAS. TEMPORARY VALVES AND GAUGES

HAVE BEEN INSTALLED.

1. RELIEVE PRESSURE PRIOR TO OPENING LINES OR

MAKING FIELD CONNECTIONS.

2. REMOVE CHARGING VALVES OR GAUGES PRIOR

TO PRESSURIZING SYSTEM.

3. REFER TO THIS MANUAL FOR ADDITIONAL

INFORMATION.

ESCAPING GAS MAY CAUSE INJURY !

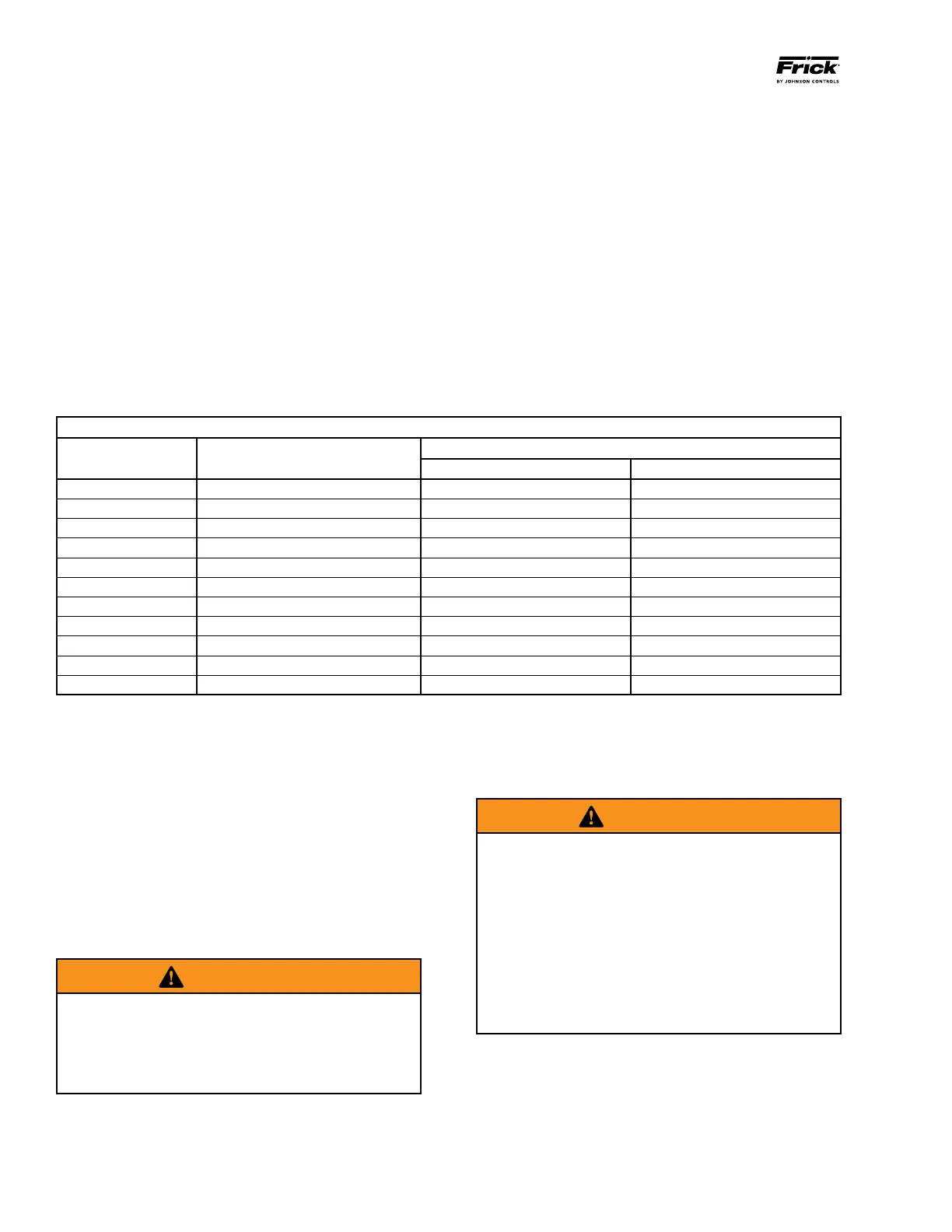

SAE STRAIGHT THREAD O-RING FITTINGS - ASSEMBLY PROCEDURE FOR RXF 58 - 101

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs, nicks

and scratches or any foreign material.

2. If the O-ring is not pre-installed to the tting on the

male end, install the proper size O-ring.

3. Lubricate the O-ring with a light coating of system oil or

petroleum jelly.

4. Screw the tting into the female port until the hex at

contacts the port face. Light wrenching may be necessary.

5. Tighten to the appropriate torque value shown in the

Assembly Torque Table.

ASSEMBLY TORQUE TABLE

Straight and Adjustable Fittings or Plugs (steel)

Fitting Size SAE Port Thread Size

Assembly Torque

Inch lb Foot lb

2 5/16 – 24 65 ± 5 5.5 ± 0.5

3 3/8 – 24 130 ± 10 11 ± 1.0

4 7/16 – 20 170 ± 10 14 ± 1.0

5 1/2 - 20 260 ± 15 22 ± 1.0

6 9/16 – 18 320 ± 20 27 ± 2.0

8 3/4 - 16 500 ± 25 42 ± 2.0

10 7/8 – 14 720 ± 30 60 ± 2.5

12

1Z\zn – 12

960 ± 50 80 ± 5.0

16

1B\zn – 12

1380 ± 75 115 ± 6.0

20

1B\, – 12

2700 ± 150 225 ± 12.0

24

1M\, - 12

3000 ± 160 250 ± 12.0

When performing maintenance or replacing the compressor,

the hydraulic tubing may need to be removed and re-

installed. The following procedure outlines the proper

installation of SAE straight thread ttings to SAE straight

thread ports.

The male and female ends of SAE straight thread O-ring

ports have UN/UNF straight threads. An elastomeric O-ring

is tted to the male end. On assembly, the O-ring is rmly

sandwiched between the angular sealing surface of the

female port and the shoulder of the male end. Sealing is

thus affected and maintained by the O-ring compression

which results from the clamping force generated by the

tightening action. The straight threads do not offer sealing

action; they provide the resistance (holding power) for

service pressure.

Loading...

Loading...