070-450 IOM (NOV 13)

Page 15

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

RIGGING AND HANDLING

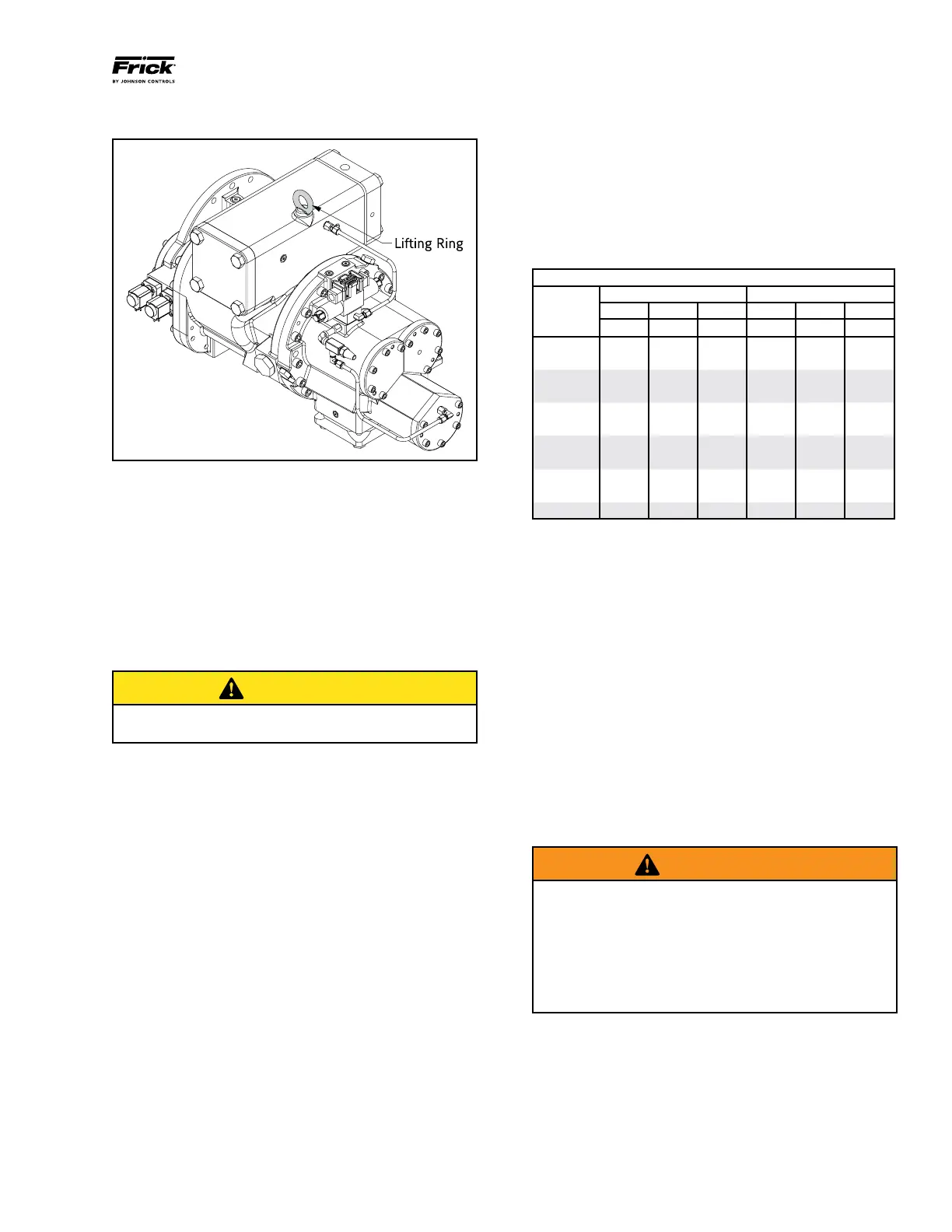

Figure 3 - Lifting Ring

The compressor can be moved with rigging, using a crane

or forklift, by hooking into the two lifting rings at each end

of the main housings. The compressor lifting rings shall only

be used to lift the compressor itself. See Figures 3 and 4.

FOUNDATION

Each XJF Rotary Screw Compressor is shipped mounted on

a wooden skid, which must be removed prior to unit

installation.

CAUTION

Allow proper spacing for servicing (see Dimensional

Outline Drawing).

The rst requirement of the compressor foundation is that

it must be able to support the weight.

XJF 95 600 lb

XJF 120 845 lb

XJF 151 1,210 lb

Screw compressors are capable of converting large

quantities of shaft power into gas compression in a relatively

small space. The compression process creates relatively

high frequency vibrations that require sufcient mass in the

base to effectively dampen them.

The best insurance for a trouble-free installation is to rmly

anchor the compressor to a suitable foundation using

proper bolting and by preventing piping stress from being

imposed on the compressor. Once the compressor is rigged

into place, its feet must be shimmed to level it. There must

be absolutely no stresses introduced into the compressor

body due to bolting of the feet and anges.

The compressor motor mount is not designed to carry the

unsupported weight of the motor. The full motor weight

must be supported using the motor lifting point during the

motor installation process. After the necessary bracket to

support the motor have been welded into place on the

package and the rear motor feet and the motor mount have

been bolted into place, the weight of the motor can rest on

the support bracket and the motor mount.

In any screw compressor installation, suction and discharge

lines should be supported in pipe hangers (preferably within

2 feet of vertical pipe run) so that the lines won’t move if

disconnected from the compressor. See table for Allowable

Flange Loads.

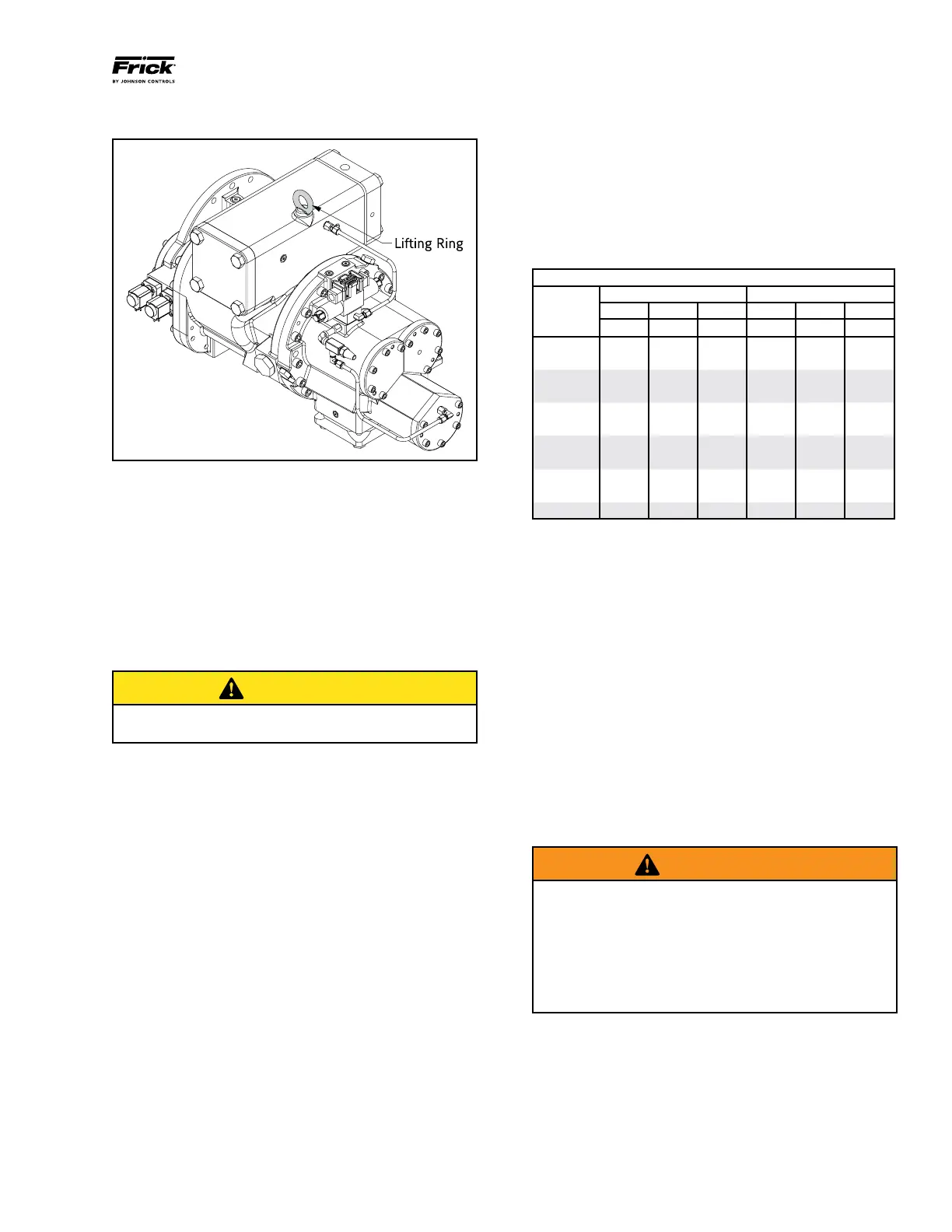

ALLOWABLE FLANGE LOADS

NOZ. MOMENTS (ft-lbf) LOAD (lbf)

SIZE AXIAL VERT. LAT. AXIAL VERT. LAT.

NPS M

R

M

C

M

L

P V

C

V

L

1 25 25 25 50 50 50

1.25 25 25 25 50 50 50

1.5 50 40 40 100 75 75

2 100 70 70 150 125 125

3 250 175 175 225 250 250

4 400 200 200 300 400 400

5 425 400 400 400 450 450

6 1,000 750 750 650 650 650

8 1,500 1,000 1,000 1,500 900 900

10 1,500 1,200 1,200 1,500 1,200 1,200

14 2,000 1,800 1,800 1,700 2,000 2,000

CUSTOMER CONNECTIONS

As a minimum you must make oil connections to the

locations shown on the compressor port location drawings

in addition to suction and discharge.

Other connections are available for instrumentation and

service as noted on the Dimensional Outline drawing. The

electrical connections for the slide stop and the slide valve

transmitters and the solenoid valve coils must be connected

to your control system .

The oil supply system for the compressor must be designed

for a total pressure drop of no more than 15 psi with a new

oil lter element. Excessive pressure drop in the oil circuit

can prevent proper operation of the slide valve and slide

stop pistons.

COMPRESSOR OIL

WARNING

DO NOT MIX OILS of different brands, manufacturers, or

types. Mixing of oils can cause excessive oil foaming,

nuisance oil level cutouts, oil pressure loss, gas or oil

leakage and catastrophic compressor failure. CoolWare

will select a specic Frick oil for the refrigerant being

used. Depending on the application, a different oil can be

selected provided it is of the proper viscosity and is com-

patible with the refrigerant and compressor elastomers.

OIL PUMP

If your XJF compressor application requires an oil pump, it

is recommended that a strainer be mounted upstream to

protect it. Frick supplied pumps are a positive displacement

gear type that must have a safety relief valve to ensure the

oil pressure will not be more than 50 psi above compressor

discharge pressure for all models.

Loading...

Loading...