070-450 IOM (NOV 13)

Page 20

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

3. Set the compressor Vi to 3.5, then record the voltage that

is shown on the Slide Valve calibration screen for the cur-

rent Slide Valve and 0% Slide Valve positions. The difference

between these voltages must be in the 0.95 - 1.15 Vdc range.

4. Set the compressor Vi to 5.0, then record the voltage that

is shown on the Slide Valve calibration screen for the cur-

rent Slide Valve and 0% Slide Valve positions. The difference

between these voltages must be in the 0.73 - 0.93 Vdc range.

5. If the above voltage measurements are all in range, the

Volumizer II is working properly. If any of the voltages are

out of range, go to the troubleshooting section.

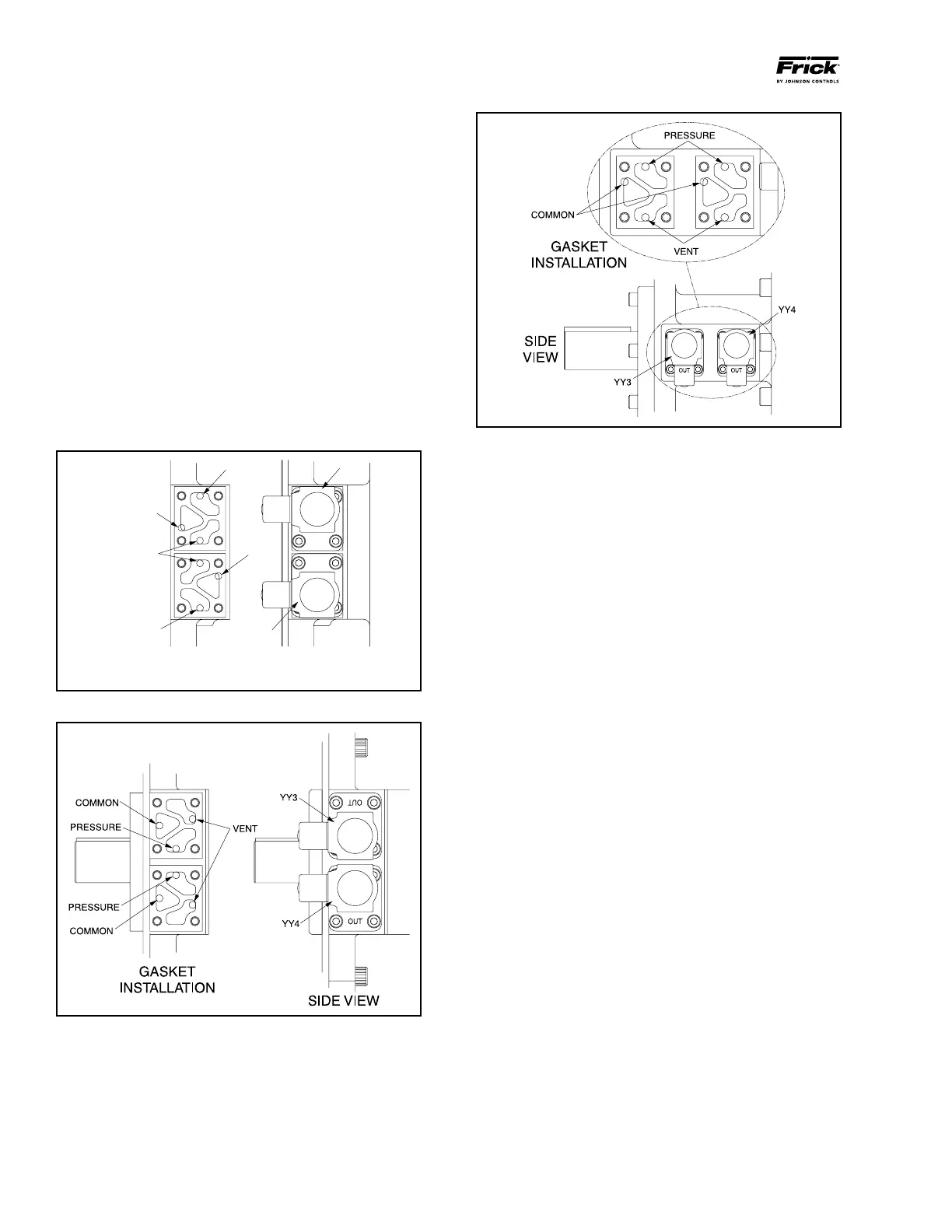

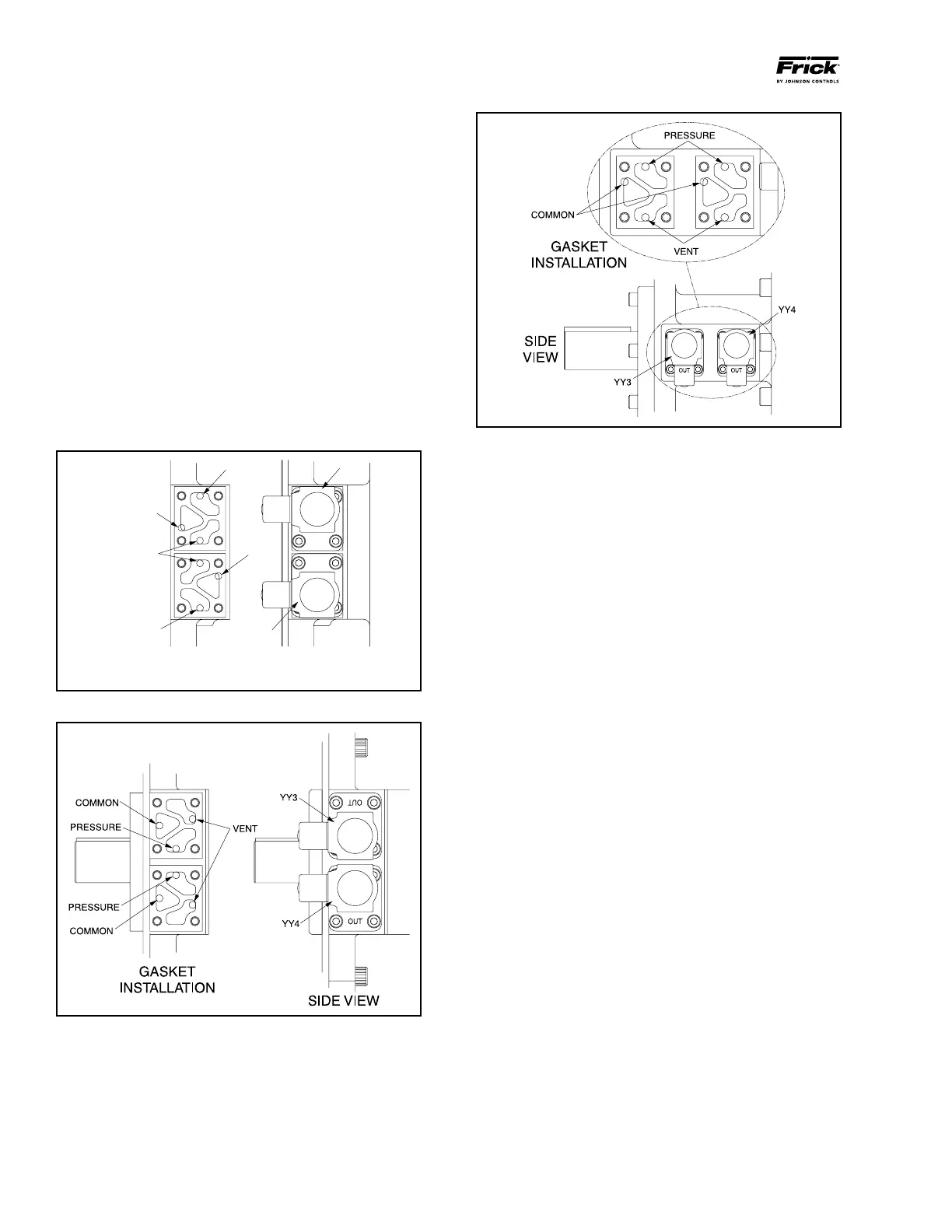

Proper installation of the Vi control valves and gaskets is

essential to the operation of this equipment. Incorrectly

installed parts may cause the compressor to operate at the

wrong Vi, or to load or unload improperly. Operation at the

wrong compressor Vi can cause excessive power consump-

tion, noise, vibration, or excessive oil foaming. See Figures

12 - 14 for correct installation of gaskets and location of

solenoids.

OUT

OUT

GASKET INSTALLATION SIDE VIEW

PRESSURE

PRESSURE

COMMON

COMMON

VENT

YY3

YY4

Figure 12 - XJF 95 Vi Control

Figure 13 - XJF 120 Vi Control

Figure 14 - XJF 151 Vi Control

LOW AMBIENT OPERATION

It is recommended that package oil separators be insulated

as a minimum requirement to preserve the heat generated

by the oil heaters, to prevent condensation and secure

lubrication at start-up.

Loading...

Loading...