070-450 IOM (NOV 13)

Page 18

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

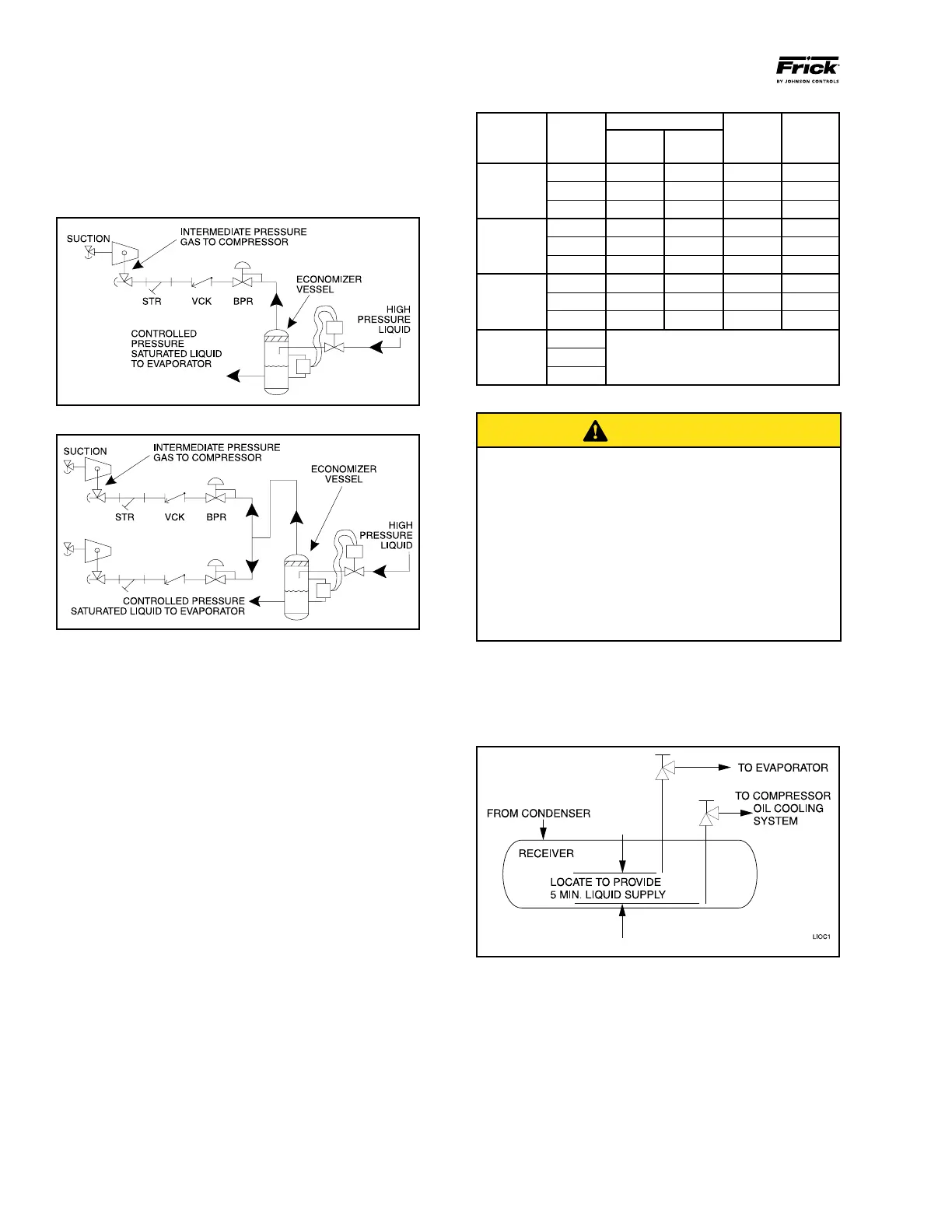

run at partial load, exposing the economizer port to suction

pressure. In the case of a ash vessel, there is no need for

the redundancy of a back-pressure regulating valve on the

vessel and each of the multiple compressors. Omit the BPR

valve on the ash economizer vessel and use one on each

compressor, as shown in Figure 7.

Figure 6 - Flash Economizer System

Figure 7 - Multiple Compressor Flash Economizer System

LIQUID INJECTION OIL COOLING

The liquid injection system provided on the unit is self-con-

tained but requires the connection of the liquid line sized as

shown in the table.

High-stage compressor units may be supplied with single-port

(low Vi, side, or closed thread) or dual-port (low Vi and high Vi),

liquid injection oil cooling. Single port will be furnished for low

compression ratio operation and dual port for high compres-

sion ratio operation. Booster compressor units use single-port

(High Vi), liquid injection oil cooling due to the typically lower

compression ratios.

The control system on high-stage units with dual-port, liquid

injection oil cooling switches the liquid refrigerant supply to

the high port when the compres sor is operating at higher

compression ratios (3.5 Vi and above) for best efciency.

Where low compres sion ratios (low condensing pressures)

are anticipated, thermo syphon or water-cooled oil cooling

should be used.

Liquid line sizes and the additional receiver volume (quanti-

ty of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in the following table:

CONDITIONS: High Stage at 0°F Evap, and 95°F Cond, 10°F

suction superheat; Booster at -40°F Evap, 95°F Cond, 20°F

Intermediate, and 10°F suction superheat; R-507 unloaded

slide valve.

XJF

MODEL

LIQ. LINE SIZE*

5 MIN

SUPPLY

POUNDS

LIQUID

VOLUME

CU. FT

REFRIG

PIPE

SCH 80

TUBING

OD

R-717

HIGH

STAGE

95 3/8 – 12 0.3

120 1/2 – 33 0.9

151 3/4 – 65 1.8

R-507

HIGH

STAGE

95 3/8 1/2 24 0.4

120 3/8 1/2 60 1.0

151 1/2 5/8 99 1.6

R-717

BOOSTER

95 3/8 – 3 0.1

120 3/8 – 8 0.2

151 3/8 – 14 0.4

R-507

BOOSTER

95

No oil heat of rejection

at this condition

120

151

* 100 ft. liquid line. For longer runs, increase line size accordingly.

CAUTION

It is imperative that an uninterrupted high-pres sure

liquid refrig erant be provided to the injection system

at all times. Two items of EXTREME IMPORTANCE are

the design of the receiver/liquid injection supply and

the size of the liquid line. It is recommended that the

receiver be oversized sufciently to retain a 5-minute

supply of refrigerant for oil cooling. The evaporator

supply must be secondary to this considera tion. Failure

to follow these requirements causes wire draw which

can result in damage to the expansion valve, loss of oil

cooling, and intermittant oil cooling. One method of

ac complishing this is described below.

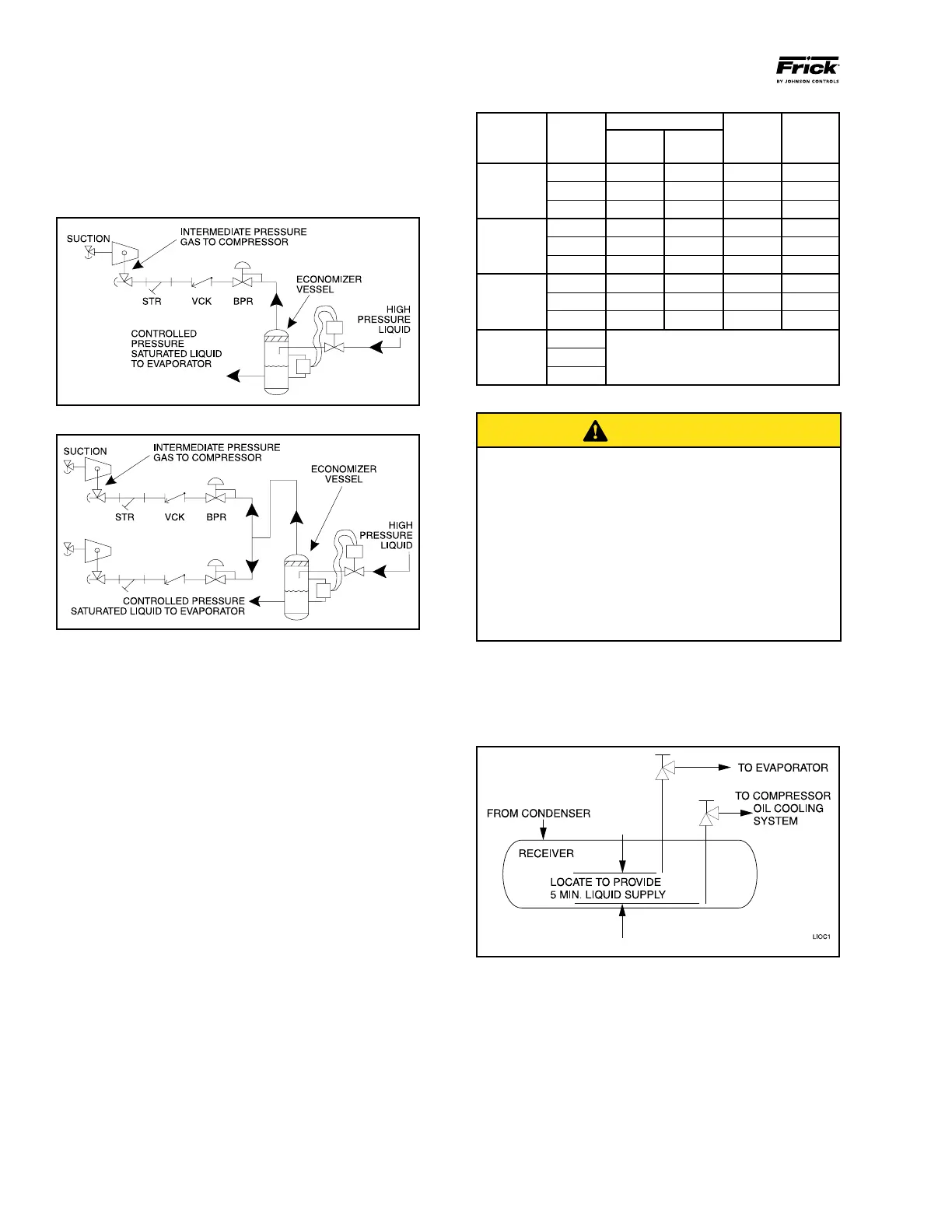

DUAL DIP TUBE METHOD

The dual dip tube method uses two dip tubes in the re ceiv-

er. The liquid injection tube is below the evaporator tube to

assure continued oil cooling when the receiver level is low.

See Figure 8.

Figure 8

DEHYDRATION / EVACUATION TEST

Evacuate the system to 1000 microns. Valve off the vacuum

pump and hold vacuum for one hour.

Pass – Vacuum cannot rise more than 500 microns during

one hour hold period.

Fail – Vacuum rise is more than 500 microns during one

hour hold period. Identify and repair any system leaks.

Repeat vacuum test until requirements are met.

Loading...

Loading...