070-450 IOM (NOV 13)

Page 16

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

COMPRESSOR

MOUNTING

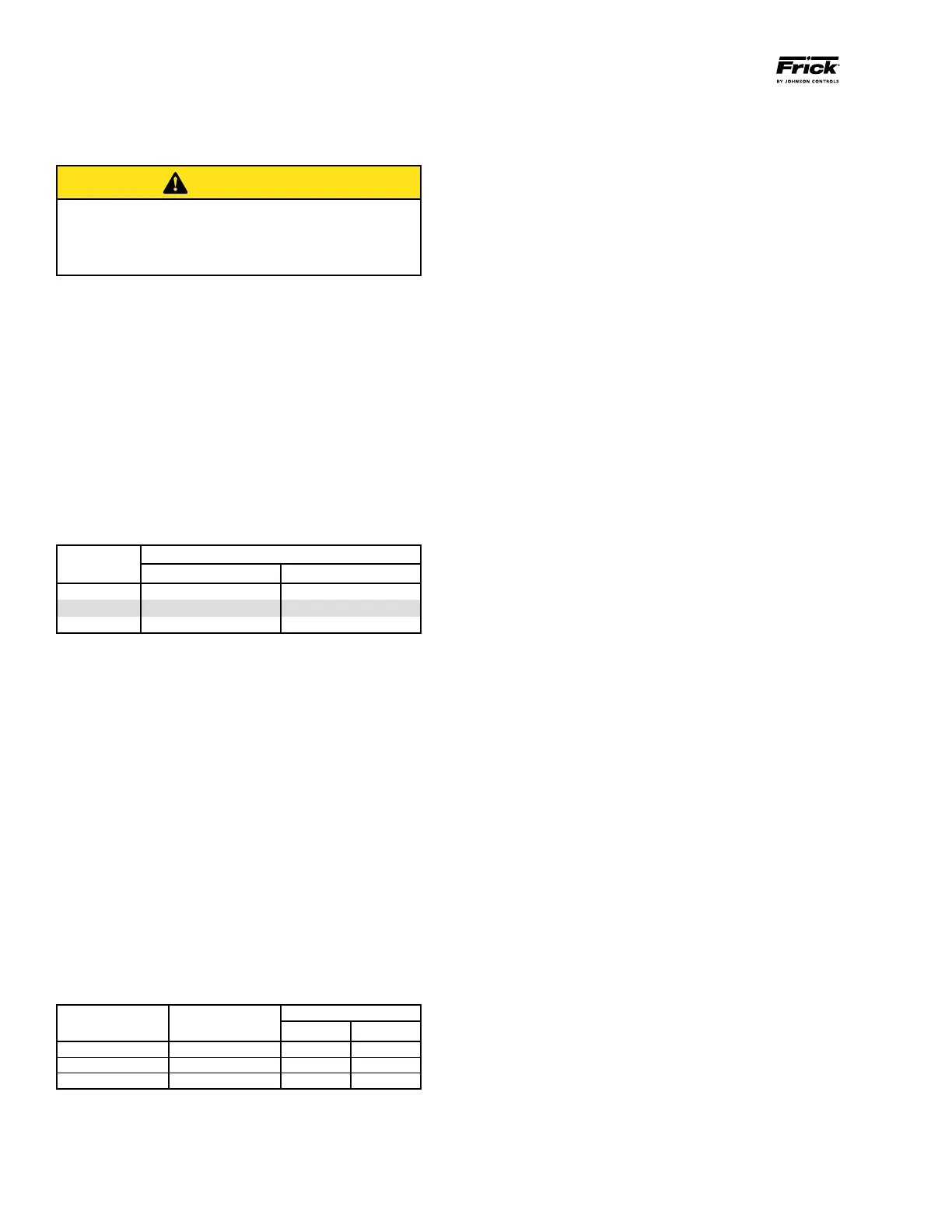

CAUTION

To prevent injury or damage to components, and for

complete details regarding pressurized refrigerant vapor

transfer and recovery, see the current Installation-

Operation-Maintenance Manual for your unit.

1. Place a new gasket on the oil separator ange. (Contact

the Baltimore Parts Center for replacement gaskets, Ph:

800-336-7264). Assemble the new compressor to the tunnel

and hand tighten the bolts in a star pattern. Then torque to

1/3 of table value in star pattern increasing by 1/3’s to full

torque. Refer to Table 3 for torque specications.

2. Set the compressor and motor assembly on the separator

ange and align the oil separator ange bolt holes to the

compressor discharge ange bolt holes while supporting

the assembly with a hydraulic piston underneath the motor.

The hydraulic piston must support the motor weight, motor

support / tunnel weight, plus 1/2 the compressor weight.

Reference Table 2 for compressor weights.

TABLE 2 - COMPRESSOR WEIGHT

XJS/XJF

Compressor Weight - Approximate

lb kg

95 600 272

120 845 383

151 1,210 549

3. Insert the bolts through the oil separator ange and into

the compressor discharge ange. Tighten bolts using a star

pattern. Lube bolts then nger tight on all bolts, then torque

to 1/3 of table value in star pattern increasing by 1/3’s to full

torque. Reference Table 3.

4. The motor feet should rise above the support base. If

not, remove the compressor, add another gasket on top of

the oil separator ange and repeat steps 4 & 5.

5. While the assembly is still supported, measure the

clearance between the motor feet and base plate with a

feeler gage. Shim the motor feet to gage reading plus .002”

gap between each motor foot and the support base. Then,

bolt the motor to the mounting base and torque the motor

mounting bolts to 250 ft-lb.

6. Connect all tubing and pipe connections to the

compressor and all wiring to the motor.

7. Remove the lifting assembly.

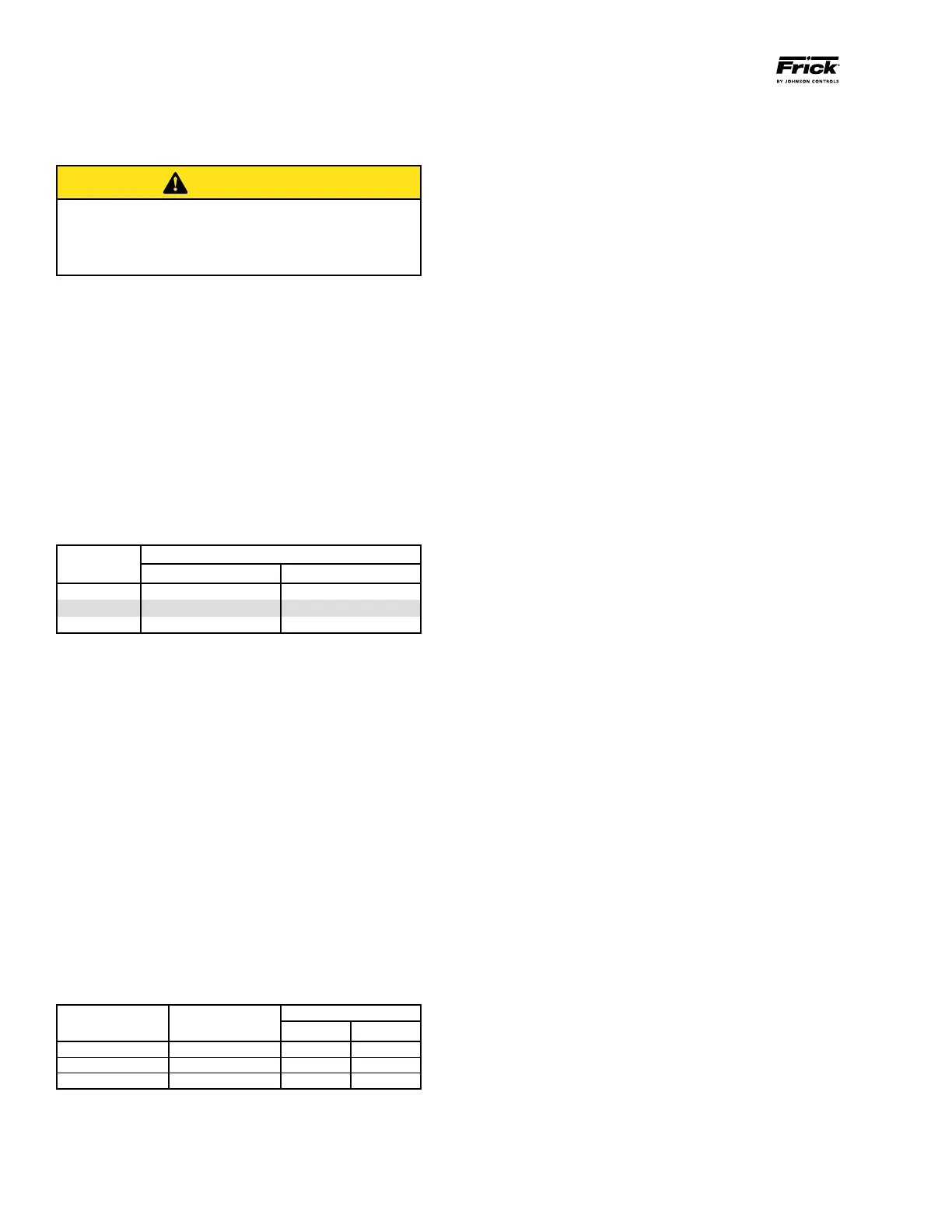

TABLE 3 - BOLT TORQUE VALUE

Compressor

Model

Screw Size

Torque

ft-lb NM

XJF 95

1/2 or 5/8

58 79

XJF 120 1/2 or 5/8 58 79

XJF 151

5/8 or 3/4

144 195

COMPRESSOR/MOTOR COUPLING REQUIREMENTS.

XJF compressors are arranged for direct motor drive and

require a exible drive coupling to connect the compressor

to the motor.

If you are using the Johnson Controls – Frick motor mount,

the mount is machined to ensure that motor to compressor

alignment is in specication (see the above “MOTOR

MOUNTING” section for mounting details).

If you are using a foot mounted motor, it is essential that

the coupling be properly aligned to ensure proper bearing

and seal performance.

1. Coupling must be selected and installed so that it

doesn’t transmit any axial load to the compressor

shaft.

2. Set up the minimum distance between compressor

shaft and motor shaft to allow for seal removal (see

Outline drawings).

3. Coupling must be able to take up any misalignment

between motor and compressor. It is critical to the

life of the shaft seal that misalignment is kept to the

minimum possible value. Be sure to follow the coupling

manufacturer’s guidelines for checking and correcting

any misalignment. See the next section for Johnson

Controls–Frick requirements.

COUPLING ALIGNMENT REQUIREMENTS

(FOOT MOUNTED ONLY)

Coupling alignment must be performed prior to start-

up. After the compressor has been installed on the job

site, alignment must be checked again and if necessary

corrected prior to start-up. After a few hours operation,

the alignment must be checked while the package is still

hot. Correct hot alignment is critical to ensure the life of the

shaft seal and compressor bearings.

Maximum radial runout is .004” total indicator reading.

Maximum axial runout is .004” total indicator reading.

A dial indicator or another appropriate measuring device is

to be used to determine the Total Indicator Runout.

Indicator bracket sag must be checked as all brackets have

some exibility. The best way to measure this is to attach

the dial indicator and bracket on a pipe at the coupling span

distance. Zero the indicator in the 12:00 position, and rotate

the pipe so the indicator is in the 6:00 position. The reading

on the indicator in the 6:00 position is the bracket sag. This

value must be included in the dial indicator readings when

afxed to the coupling for an accurate alignment.

OIL HEATER(S)

Your package must be equipped with oil heaters that

provide sufcient heat to prevent condensation from

occurring during shutdown cycles.

Loading...

Loading...