070-450 IOM (NOV 13)

Page 3

XJF ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

THE INFORMATION CONTAINED IN THIS

DOCUMENT IS SUBJECT TO CHANGE

WITHOUT NOTICE

GENERAL INFORMATION

PREFACE

This manual has been prepared to acquaint the owner and

serviceman with the INSTALLATION, OPERATION, and

MAINTENANCE procedures as recommended by Johnson

Controls-Frick for XJF Rotary Screw Compressors.

It is most important that these compressors be properly ap-

plied to an adequately controlled refrigerant or gas system.

Your authorized Johnson Controls-Frick representative should

be consulted for his expert guidance in this determination.

Proper performance and continued satisfaction with these

units is dependent upon:

CORRECT INSTALLATION

PROPER OPERATION

REGULAR, SYSTEMATIC MAINTENANCE

To ensure correct installation and application, the equipment

must be properly selected and connected to a properly

designed and installed system. The Engineering plans,

piping layouts, etc. must be detailed in accordance with the

best practices and local codes, such as those outlined in

ASHRAE literature.

A screw compressor is a VAPOR PUMP. To be certain that it

is not being subjected to pumping liquid, it is necessary that

controls are carefully selected and in good operating

condition; the piping is properly sized and traps, if necessary,

are correctly arranged; the suction line has an accumulator

or slugging protection; that load surges are known and

provisions are made for control; operating cycles and stand

still periods are reasonable; and that high side components

are sized within system and compressor design limits.

NOTICE

It is required that the discharge temperature be kept

high enough to prevent condensation of any moisture

in the compressor and oil separator.

DESIGN LIMITATIONS

XJF compressors are designed for operation within the

pressure and temperature limits which are specied by

Johnson Controls-Frick and the Johnson Controls-Frick

selection software COOLWARE

™

. They are primarily used for

compressing refrigerant gas and most hydrocarbon gasses.

If your application is for sour gas, there are special requirements

to protect the compressor. Contact Johnson Controls - Frick

Compressor Engineering for application details.

JOB INSPECTION

Immediately upon delivery examine all crates, boxes and

exposed compressor and component surfaces for damage.

Unpack all items and check against shipping lists for any

discrepancy. Examine all items for damage in transit.

STANDARD BARE COMPRESSOR

Items not included with bare compressor that are available

as sales order options: Motor Mount, Solenoid Valve

Capacity, Tank Drain Tubing (T connection), Oil Feed Line

(P connection), Connection Fittings, Coupling.

TRANSIT DAMAGE CLAIMS

All claims must be made by consignee. This is an ICC re-

quirement. Request immediate inspection by the agent of

the carrier and be sure the proper claim forms are execut-

ed. Report damage or shortage claims immediately to

Johnson Controls-Frick Sales Administration Department,

in Waynesboro, PA.

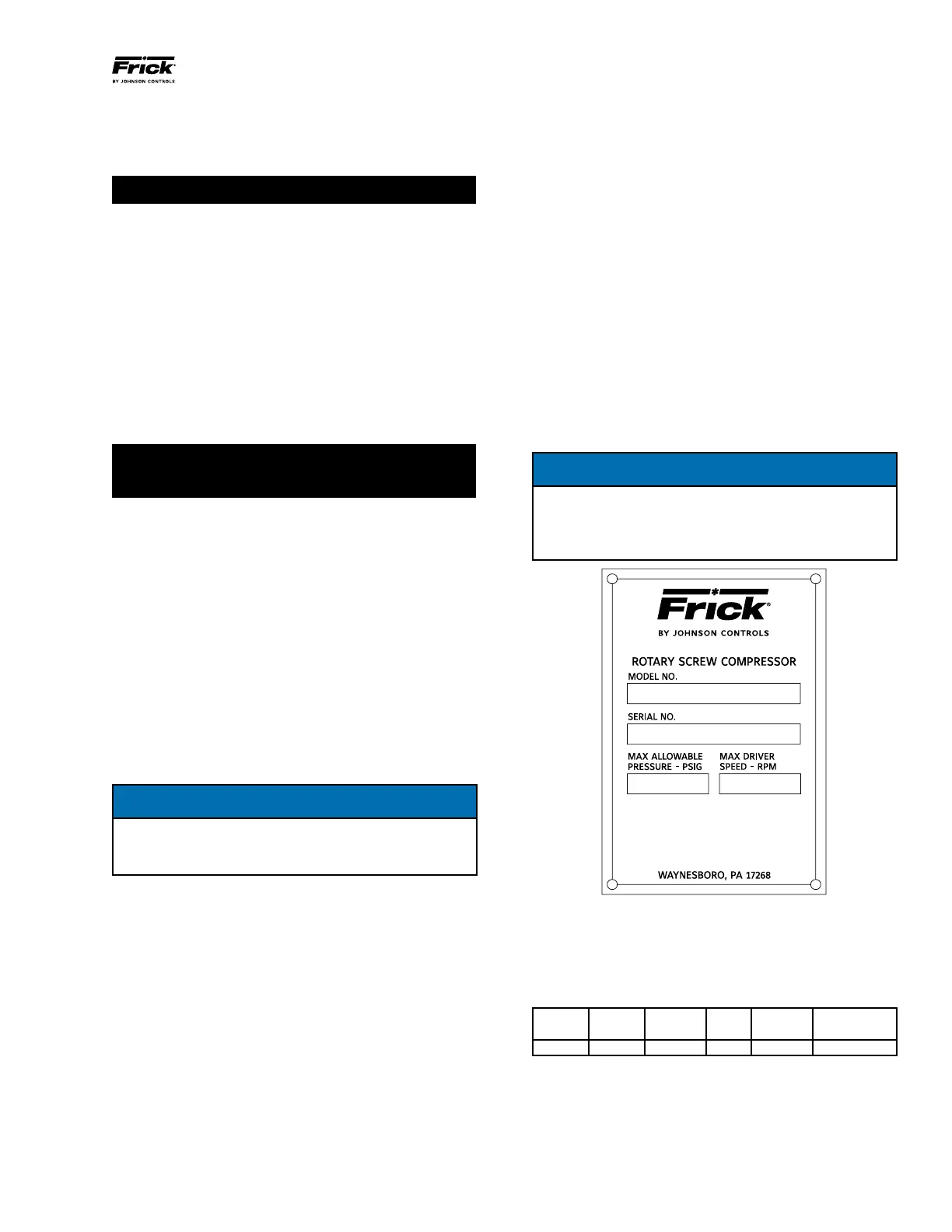

COMPRESSOR IDENTIFICATION

Each compressor has an identication data plate, containing

compressor model and serial number mounted on the

compressor body.

NOTICE

When inquiring about the compressor or unit, or

ordering repair parts, provide the MODEL, SERIAL, and

JOHNSON CONTROLS - FRICK SALES ORDER NUMBERS

from the data plate. See Figure 1.

Figure 1 - Identication Data Plate

Rotary screw compressor serial numbers are dened by the

following information:

EXAMPLE: 10240A90000015Z

GLOBAL ADDITIONAL

PLANT DECADE MONTH YEAR SEQ NO. REMARKS

1024 0 A 9 0000015 Z

Month: A = JAN, B = FEB, C = MAR, D = APR, E = MAY, F =

JUN, G = JUL, H = AUG, K = SEP, L = OCT, M = NOV, N = DEC.

Additional Remarks: R = Remanufactured; Z = Deviation

from Standard Conguration.

Geometrical swept volume table ...

Loading...

Loading...