070-450 IOM (NOV 13)

Page 17

XJF ROTARY SCREW COMPRESSOR

INSTALLATION

OIL FILTER(S)

Your package must be equipped with full-ow oil ltration.

Typical oil lter specication β

5

= 75 according to ISO 4572

is required to obtain the recommended oil cleanliness class

16/14/11 according to ISO 4406. Frick SuperFilters

™

can be

ordered separately.

OIL COOLING REQUIREMENTS

Compressor oil needs to be cooled to control the discharge

temperature, maintain proper oil viscosity and to preserve

the life of the oil. Normally the discharge temperature will

be in the 170° - 180°F range (see CoolWare

™

).

One application that typically requires higher discharge

temperatures (as high as 250°F) is natural gas gathering at

the wellhead

1

. Moisture is normally present in the gas and

it is imperative that the discharge temperature be at least

30°F higher than the discharge dew point temperature for

the gas. Run Coolware with the “Water Saturated” block

checked to get the discharge dew point temperature for

your application. Oil temperatures as high as 170°F can be

used to achieve the necessary discharge temperature to

prevent moisture from condensing in the oil separator.

1

Contact Johnson Controls–Frick for additional information

for natural gas compression - availability of bearings for

high temperature applications - standard bearings have

limitations per Coolware that must be observed.

The main oil injection line must have a regulating valve to

permit adjustment of the oil ow to maintain the desired

discharge temperature at all times.

The use of a three-way mixing valve is recommended to

keep the oil temperature in the normal range of 120° -

140°F. The valve will provide warm oil to the compressor

quickly, reducing the pressure drop caused by cold, viscous

oil. This ensures proper oil ow and temperature over the

full range of operating conditions.

ECONOMIZER - HIGH STAGE

The economizer option provides an increase in system capac-

ity and efciency by subcooling liquid from the condenser

through a heat exchanger or ash tank before it goes to the

evapora tor. The subcooling is provided by ashing liquid in

the economizer cooler to an intermediate pressure level.The

intermediate pressure is provided by a port located part way

down the compres sion process on the screw compressor.

As the screw compressor unloads, the economizer port will

drop in pressure level, eventually being fully open to suc-

tion. Because of this, an output from the microproces sor is

generally used to turn off the supply of ashing liquid on a

shell and coil or DX economizer when the capacity falls below

approximately 60%-70% (85%-90% slide valve position). This

is done to improve compressor operating efciency. Please

note however that shell and coil and DX economizers can be

used at low compressor capaciti es in cases where efcien-

cy is not as important as ensuring that the liquid supply is

subcooled. In such cases, the economi zer liquid solenoid can

be left open whenever the com pressor is running.

Due to the tendency of the port pressure to fall with de-

creasing compressor capacity, a back-pressure regulator

valve (BPR) is generally required on a Flash Economizer

System (Figure 6) in order to maintain some preset pressure

dif ference between the subcooled liquid in the ash vessel

and the evaporato rs. If the back-pressure regulator valve is

not used on a ash economizer, it is possible that no pressure

difference will exist to drive liquid from the ash vessel to the

evaporators, since the ash vessel will be at suction pressure.

In cases where wide swings in pressure are anticipated in

the ash econo mizer vessel, it may be necessary to add an

outlet pressure regulator to the ash vessel outlet to avoid

overpressurizing the economizer port, which could result

in motor overload. Example: A system feeding liquid to the

ash vessel in batches.

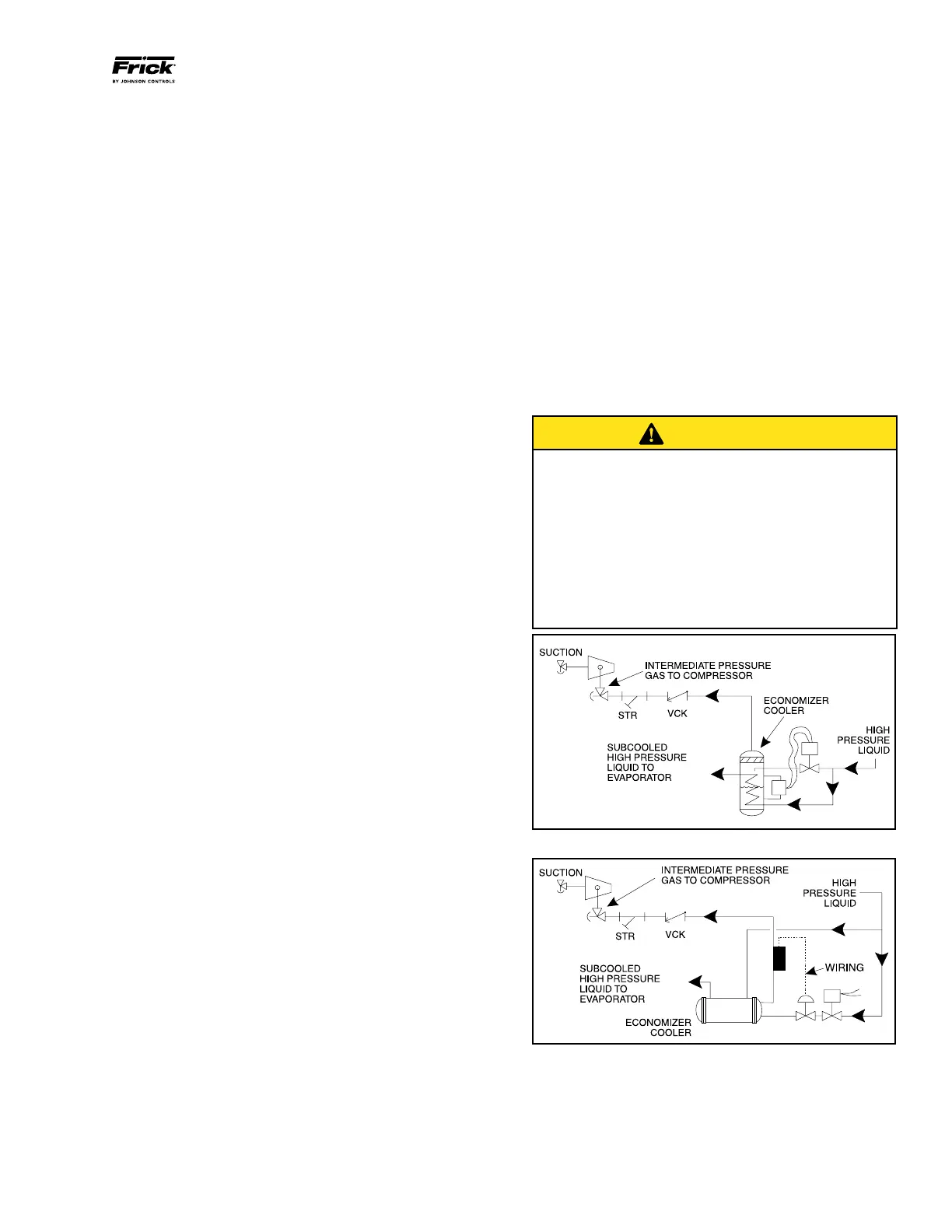

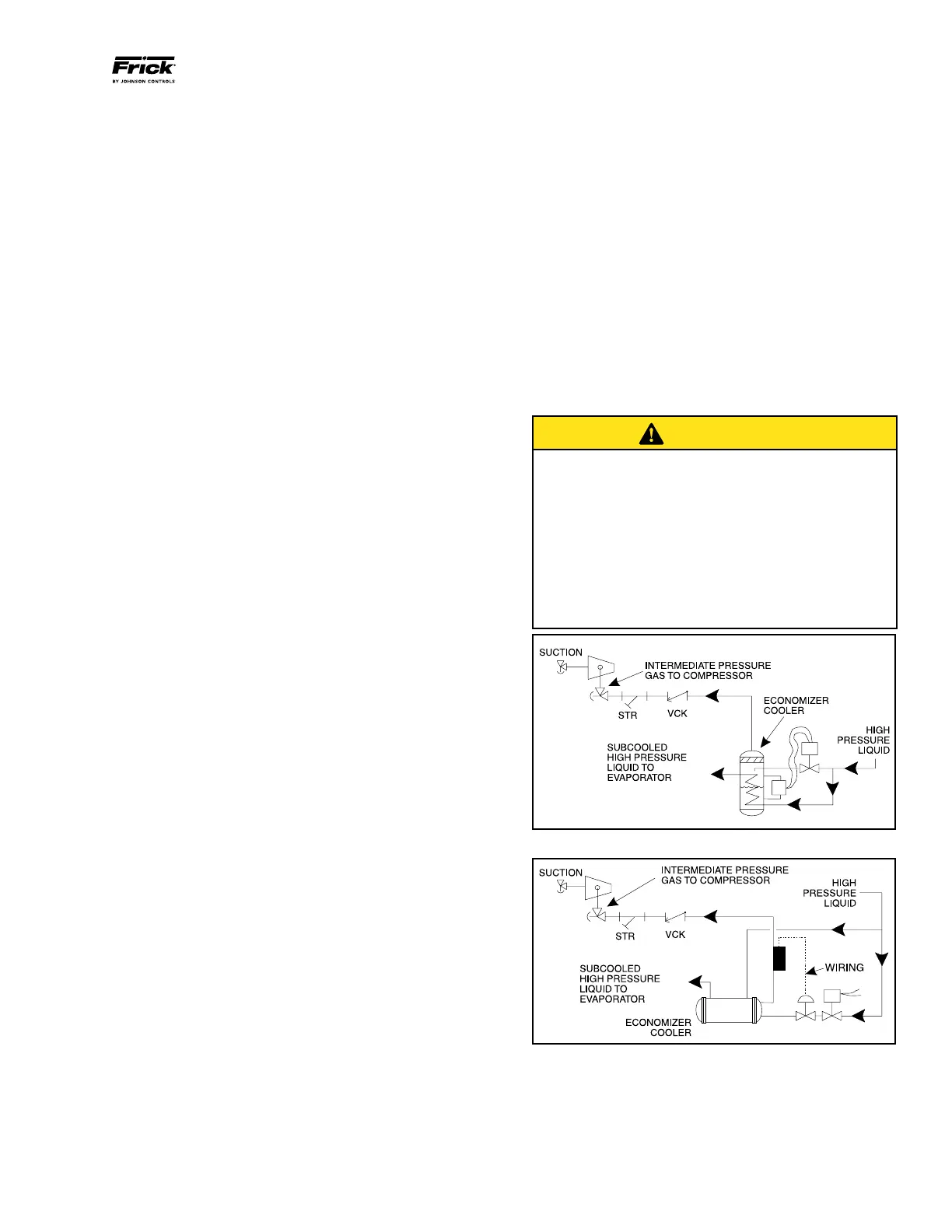

The recommended economizer systems are shown in Figures

4 – 7. Notice that in all systems there must be a strainer

and a check valve between the economizer vessel and the

economizer port on the compressor. The strainer prevents

dirt from passing into the compressor and the check valve

prevents oil from owing from the compressor unit to the

econo mizer vessel during shutdown.

CAUTION

Other than the isolation valve needed for strainer cleaning, it

is essential that the strainer be the last device in the

economizer line before the compres sor. The strainer must

be strong enough to handle the gas pulsations from the

compressor. Johnson Controls-Frick recommends an R/S

or Hansen strainer. Also, piston-type check valves are

recom mended for installation in the economizer line, as

opposed to disc-type check valves. The latter are more

prone to gas-pulsation-induced failure. The isolation and

check valves and strainer should be located as closely as

possible to the compressor, preferably within a few feet.

Figure 4 - Shell And Coil Economizer System

Figure 5 - Direct Expansion Economizer System

For refrigeration plants employing multiple compressors on

a common economizing vessel, regardless of economizer

type, each compressor must have a back-pressure regulat-

ing valve in order to balance the economizer load, or gas

ow, between compressors. The problem of balancing load

becomes most important when one or more compressors

Loading...

Loading...