070-450 IOM (NOV 13)

Page 24

XJF ROTARY SCREW COMPRESSOR

MAINTENANCE

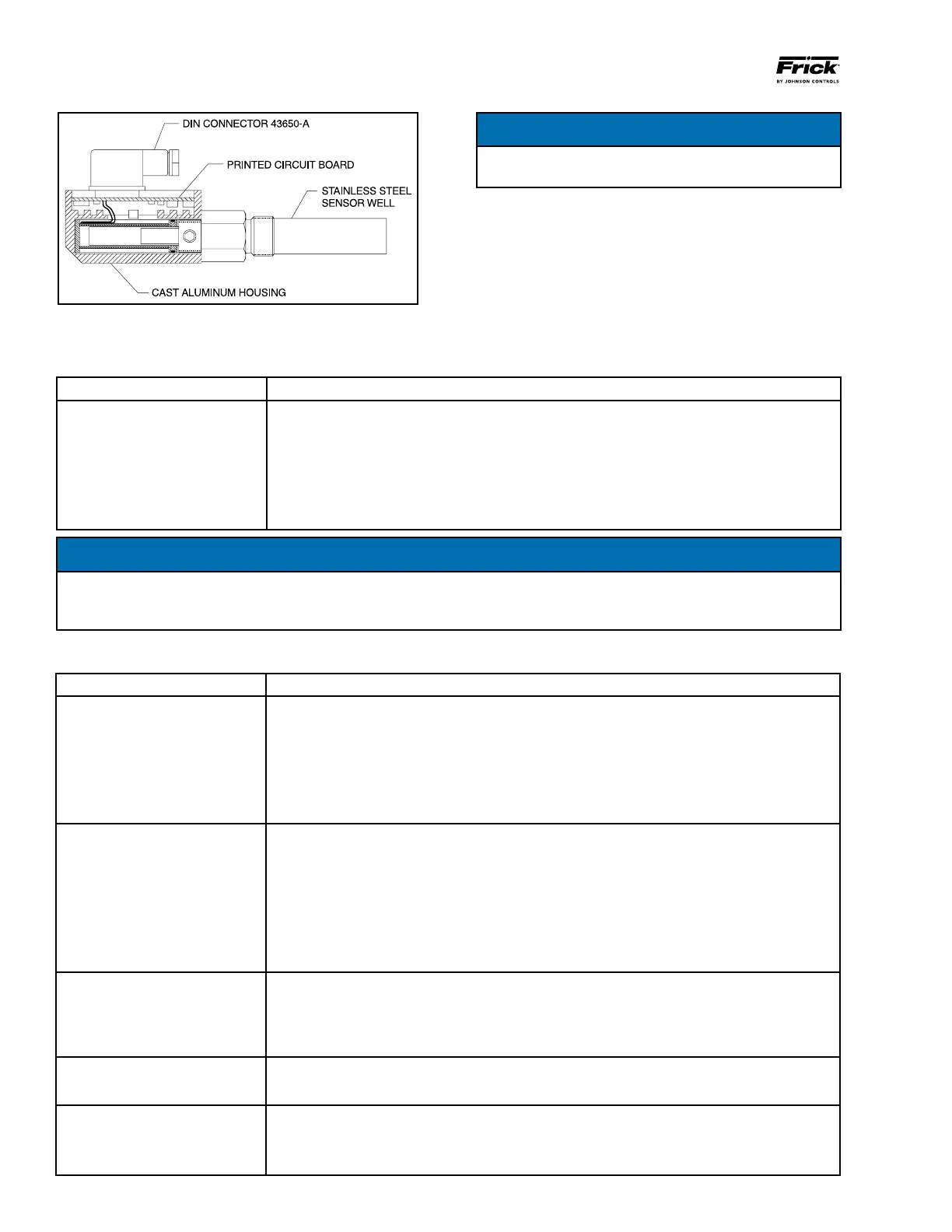

Figure 15 - Slide Valve Transmitter

NOTICE

For calibration of the Slide Valve unit, refer to the Ana-

log Calibration instructions in publication 090.040-O.

BARE COMPRESSOR MOUNTING

Refer to publication 070.660-SM.

TROUBLESHOOTING THE COMPRESSOR

SYMPTON PROBABLE CAUSES and CORRECTIONS

EXCESSIVE NOISE and

VIBRATION

Loose bolts on compressor mounting. Tighten bolts.

No oil getting to compressor. Check oil level, oil lter and oil pressure.

Bearing damage or excessive wear.

Coupling loose on shaft. Tighten coupling. Replace if damaged.

Volumizer not adjusted correctly. Readjust.

Refrigerant ood-back. Correct system problem.

NOTICE

Unless the Service Technician has been certied by Johnson Controls – Frick to rebuild our compressors, troubleshooting

the compressor is limited to identifying the probable cause. If a mechanical problem is suspected contact Johnson

Controls – Frick Service. DO NOT ATTEMPT TO DISASSEMBLE COMPRESSOR.

TROUBLESHOOTING THE HYDRAULIC SYSTEM

SYMPTOM PROBABLE CAUSES and CORRECTIONS

SLIDE VALVE WILL NOT LOAD

OR UNLOAD

Solenoid coil burned out. Replace coil.

HV2 needle valve closed. Open valve.

Solenoid spool may be stuck or centering spring broken. Free spool or replace spring.

Solenoid may be mechanically actuated by inserting a piece of 3/16" rod against armature pin and pushing

spool to opposite end. Push “A” side to conrm unload capability. If valve works, problem is electrical.

Solenoid valve piston hung in bore or bolt loose. Check piston or tighten bolt.

SLIDE VALVE WILL LOAD BUT

WILL NOT UNLOAD

YY1 solenoid coil burned out. Replace coil.

Check valve in solenoid valve piston bad. Replace or repair.

Dirt inside solenoid valve preventing valve from operating both ways. Clean valve.

Solenoid may be mechanical ly actuated by inserting a piece of 3/16" rod against armature pin and pushing

spool to opposite end. Push YY1 valve to conrm unload capability. If valve works, problem is electrical.

Slipper seals worn out or damaged. Replace.

Check valve in slide valve piston sticking. Remove and clean check valve.

SLIDE VALVE WILL UNLOAD

BUT WILL NOT LOAD

YY2 solenoid coil burned out. Replace coil.

Dirt inside solenoid valve preventing valve from operating both ways. Clean valve.

Solenoid may be mechanically actuated by inserting a piece of 3/16" rod against armature pin

and pushing spool to opposite end. If valve works, the problem is electrical.

SLIDE STOP WILL NOT FUNC-

TION IN EITHER DIRECTION

Solenoid coil burned out. Replace coils.

Solenoid valve sticking. Replace valve.

SLIDE VALVE and/or SLIDE

STOP WILL NOT MOVE

Slipper seals worn out or damaged.

Unloader spindle or slide valve jammed.

Slide stop indicator rod jammed.

Loading...

Loading...