• If needed, carry out an equipotential bonding,

using the screw placed on the rear of the machine

below the frame and marked with the symbol

shown to the left.

• Make sure that the cold water supply line intended

for condensation has pressure values between 1

and 3 BAR and temperature between 13° and

20°C.

• Connect the cold water supply pipe intended for

condensation onto the machine inlet as shown in

the figure. Use a Ø1/2” fitting and place a gate

valve in the operator's reach.

• Connect the condensation water drain pipe onto

the machine outlet as shown in the figure, using a

Ø1/2” fitting.

• Always use new pipes suitable for hot water and

for pressure up to 10 bars both for delivery and

draining. Never use worn or consumed piping. Use

suitable DIN 3017 hose clamps.

• The drain pipe must have an inclination of at least

3 cm for each meter of length.

• After having connected the water inlet and outlet

pipes, with the machine stopped, open the cut-off

cock and make sure that water does not leak from

the drain.

• Turn off the master switch and press the

STORAGE button to check the following:

3. Plug connection phases.

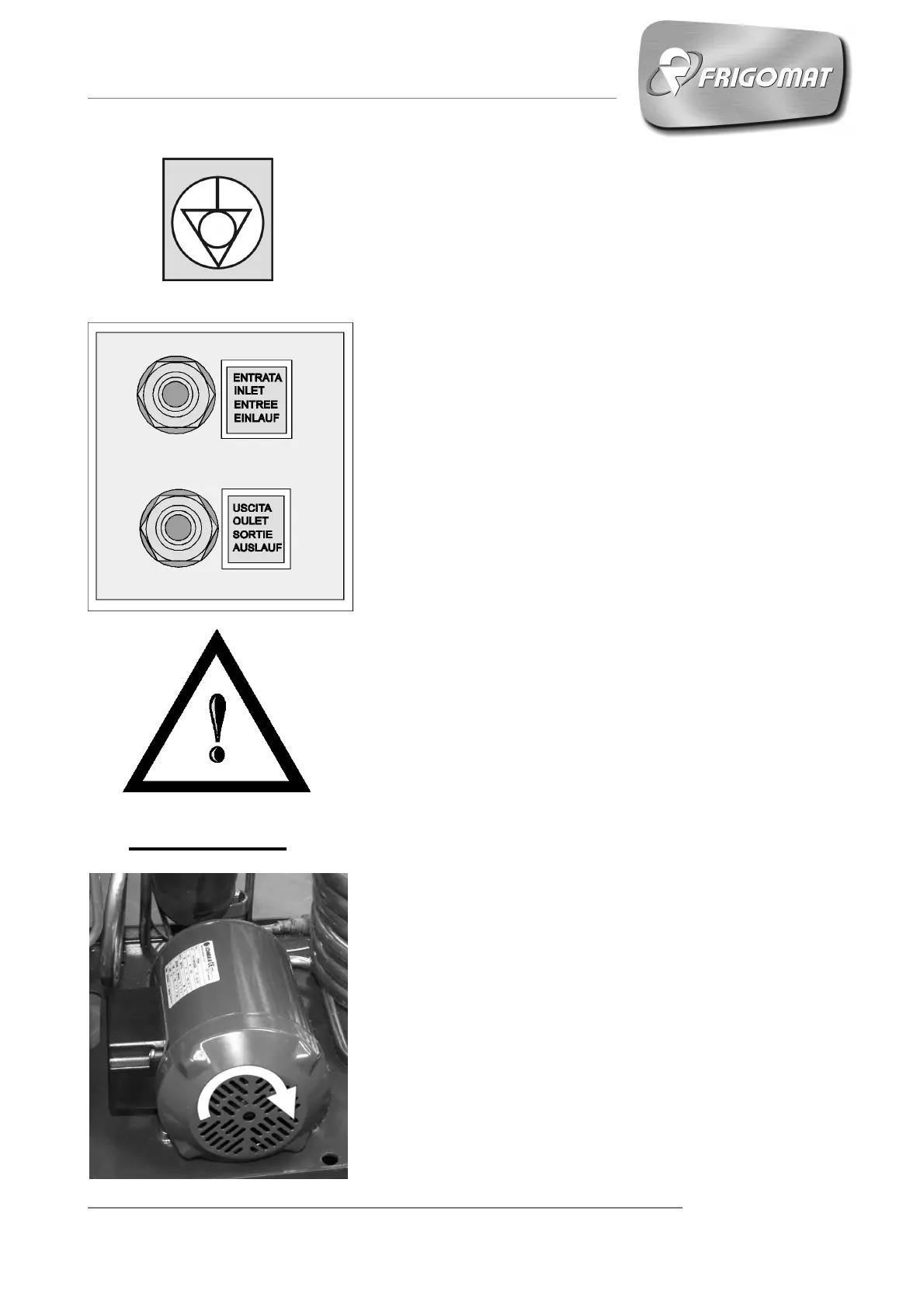

The machine beater motor is connected to an

inverter that guarantees the correct direction of

rotation (anti-clockwise) even if the phases in

the plug are inverted.

Therefore, during installation it is possible to

check that the phases are connected correctly

only by observing that the direction of rotation

of the glycol pump corresponds to that

indicated by the arrow positioned on the pump

itself.

If the direction of rotation of the glycol pump is

not correct, check for glycol leaks from the

system, over-heating and FLU alarm

indications on the LCD.

To connect the phases properly cut the power

and invert the two phase wires in the plug.

INVERTER

Loading...

Loading...