EN

FRIGOMAT KREAM 2.5 E M04.37389 R.2022.03.30 9

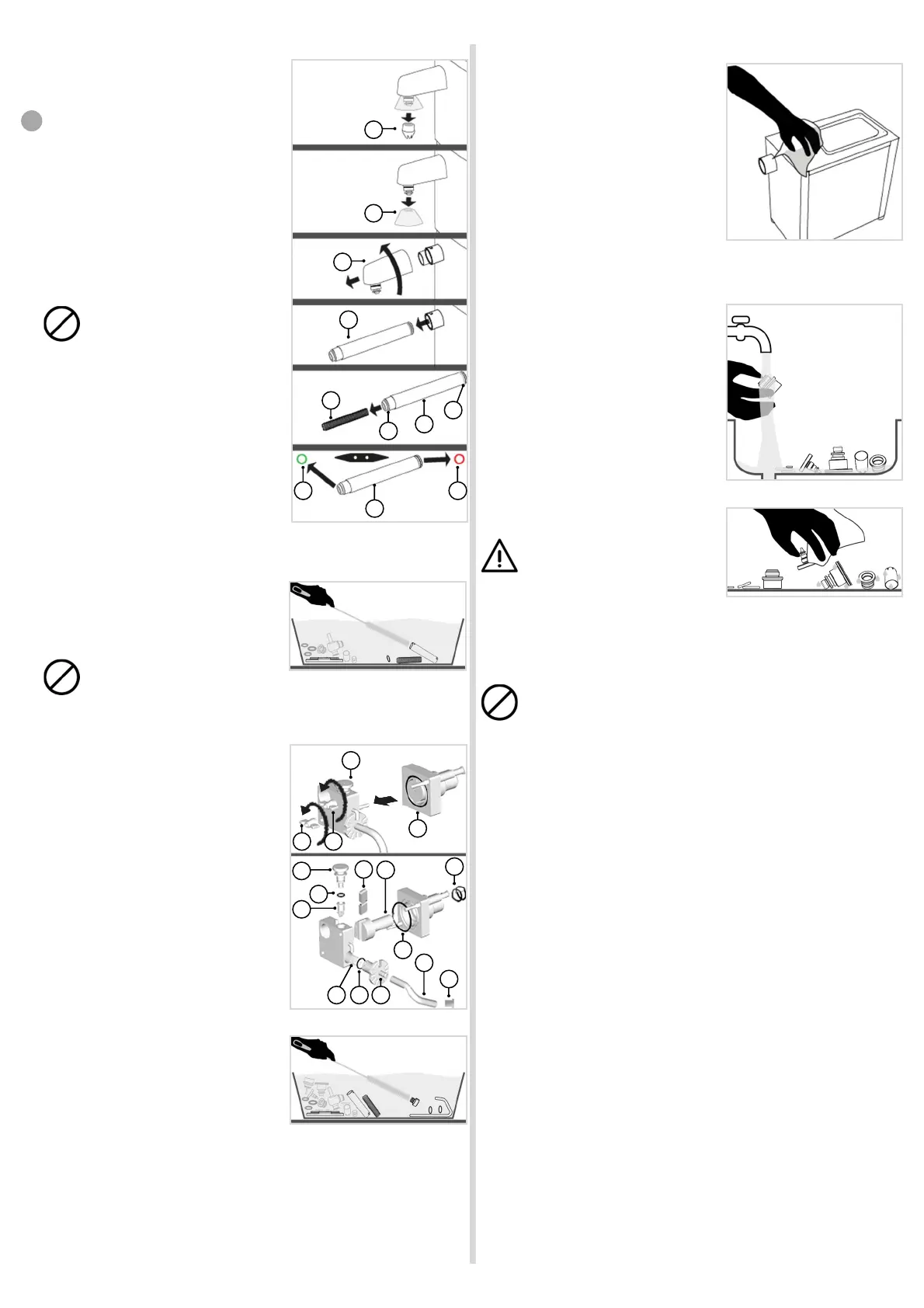

Remove and cleaning of the nozzle, of the labyrinth cover and of the

labyrinth

Wash your hands well and/or wear

disposable gloves.

Pull down the star nozzle (fig.IV/07 "a")

Pull down the splash guard (fig.IV/07 "b")

Turn the nozzle body counterclockwise

(fig.III/06 "c") and pull it towards you to

remove it from its seat.

Remove the labyrinth cover (fig.IV/07 "d")

Remove the labyrinth (fig.III/06 "e”) from the

labirynth cover (fig.III/06 "d”).

Remove the gaskets (fig.IV/07 “h, g”) using

the O-Ring disassembling tool.

Pay attention to the positioning of

the RED and GREEN gaskets on

the labyrinth cover in order to

correctly reassemble the labyrinth

cover.

Emerge the previously disassembled

components into the tub with the sanitizer

and brush the surfaces with care. Pay

special attention to the internal ducts and to

the labyrinth notches (fig.IV/08).).

All the parts previously

disassembled must remain immersed in the sanitizing

solution for the time provided by the sanitizer

manufacturer.

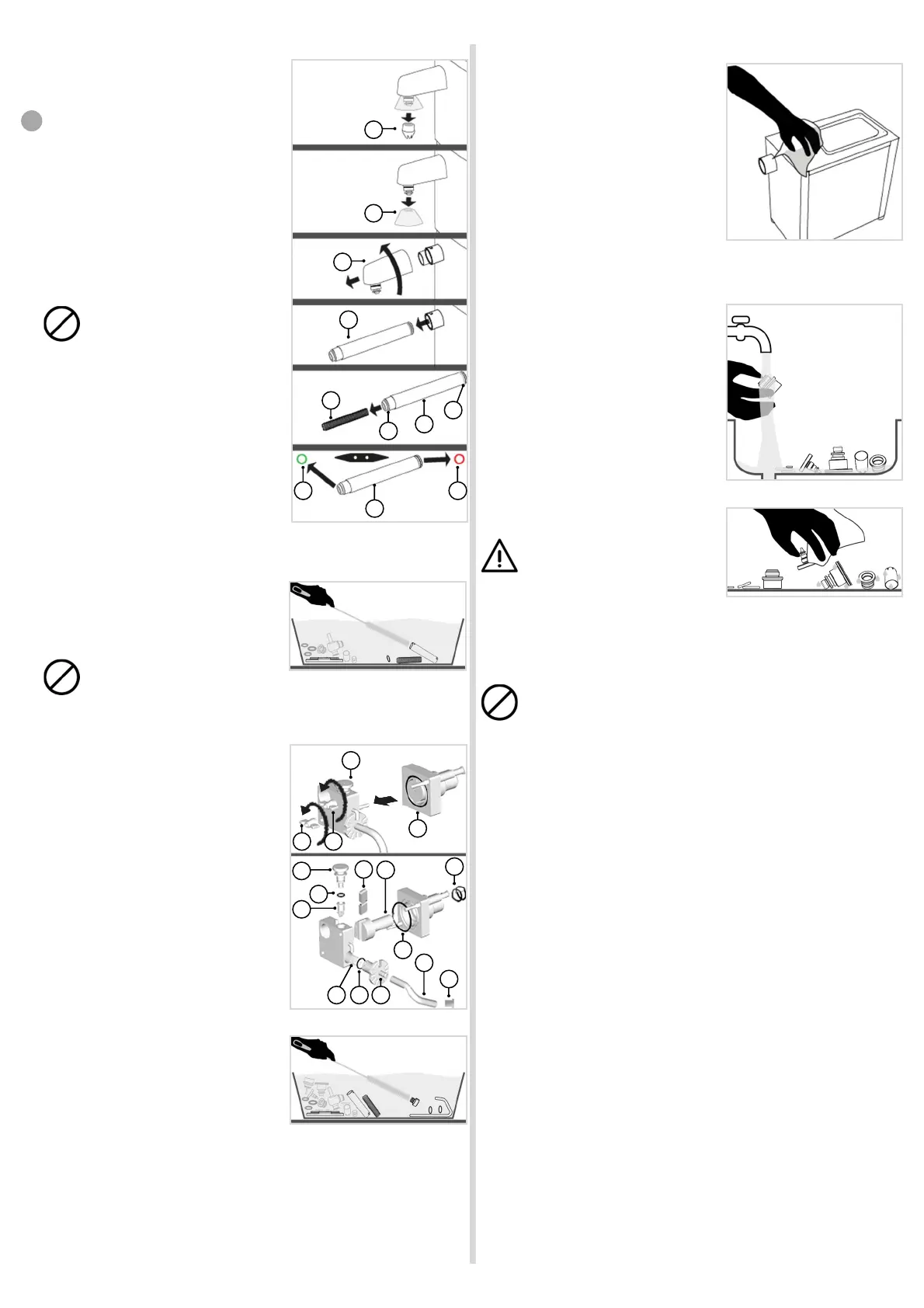

Remove and cleaning of the pump

Wash your hands well and/or wear

disposable gloves.

Unscrew the two knobs (fig.IV/09 "a")

Remove the cover (fig.IV/09 "b") from the

pump body (fig.IV/09 "c").

Remove the rotor (fig.IV/09 "d") with the

scraper (fig.IV/09 "e") and the gaskets

(fig.IV/09 “f, g”).

Remove the shutter (fig.IV/09 "h"), the rub-

ber non-return valve out (fig.IV/09 "i") and

the gasket (fig.IV/09 "k").

Remove the cream regulator (fig.IV/09 "l")

with relevant spring (fig.IV/09 "m") and

gasket (fig.IV/09 "n"), the suction hose

(fig.IV/09 “o”) and the suction tube head

(fig.IV/22 “p”).

Emerge the previously disassembled

components into the tub with the sanitizer

and brush the surfaces with care. Pay

special attention to the internal ducts

(fig.IV/10).

1.3 Sanitizing fixing parts

Immerse a disposable paper cloth in the

sanitizing liquid.

Pass the cloth over all the internal surfaces

of the main compartment. Also pass the

cloth over the external surfaces (fig.IV/11).

1.4 Rinsing and drying

Wash your hands well and/or wear

disposable gloves.

Remove from the washing tub all the

components which were previously

disassembled, immersed and brushed.

Rinse the components with plenty of cold

drinking water, taking care to remove all

possible residues of sanitizing solution

(fig.IV/12).

Also carefully rinse the fixed parts of the

machine which were treated with the

sanitizing solution.

Dry with disposable paper (fig. IV/13).

Do not use rags, sponges or

anything else to dry the

components. Make sure no dust or

other impurities come into contact with

the sanitized surfaces while they are

drying.

When all the components are dry, put them back onto the machine making

sure the gaskets and scrapers are in good conditions. If there is evidence of

excessive wear or damage, replace them.

To mount the pump again, follow the opposite sequence, re-

member to apply a thin layer of specific FRIGOMAT lubricant on

the rotor.

2 MAINTENANCE

2.1 Original spare parts

For spare parts ordering, always mention the corresponding code number

and the name reported on each table caption.

The manufacturer declines any liability for damages to people and/or things

due to employment of non-original spare parts.

2.2 Exploded view for the operator, kit and spare parts supplied

See next page diagram.

fig.IV/10

fig.IV/12

fig.IV/13

fig.IV/09

b

a a

d

e

p

o

n m

c

h

i

k

l

f

g

a

b

c

d

e

d

fig.IV/07

f g

RED/ROSSO

ROUGE/ROT/ROJA

f

g

d

GREEN/VERDE

VERT/GRUN

fig.IV/08

fig.IV/11

Loading...

Loading...