EN

FRIGOMAT KREAM 2.5 E M04.37389 R.2022.03.30 11

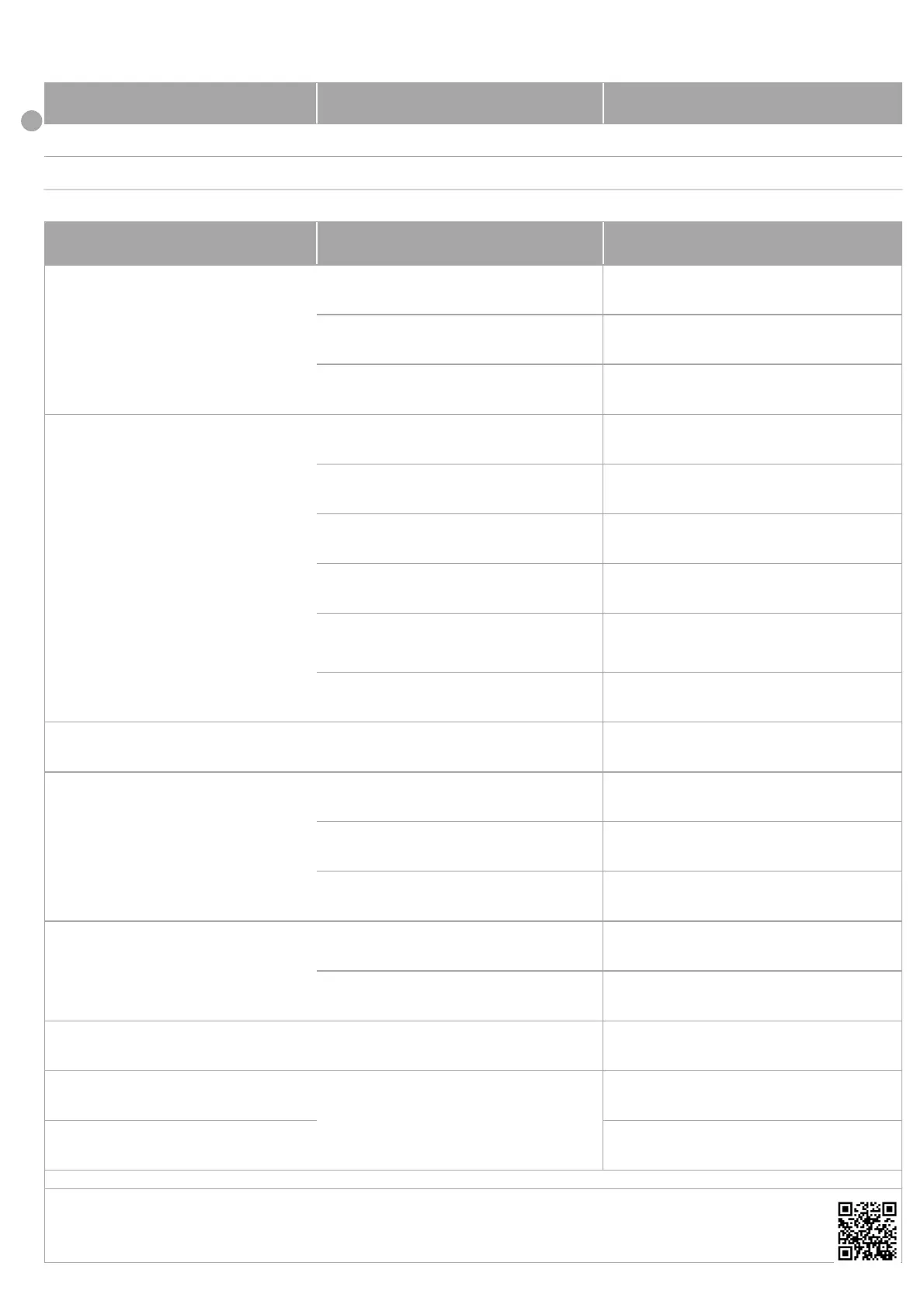

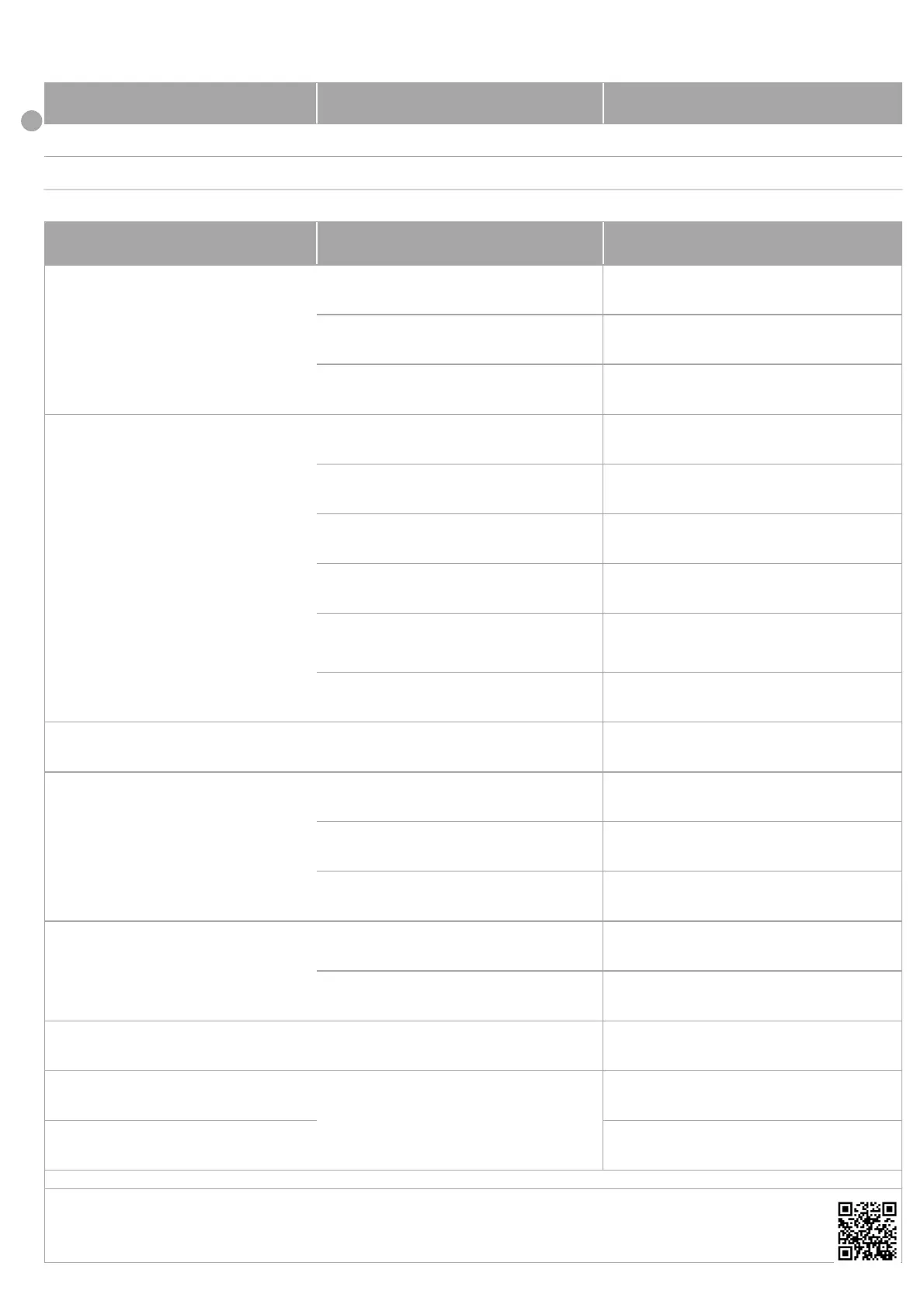

3 FAILURES IDENTIFICATION

3.1 Management of alarms

MESSAGE DESCRIPTION SOLUTION

TEV INT disconnected probe Contact the technician

1

TEV COR short-circuited probe Contact the technician

1

3.2 Problemi e soluzioni

PROBLEM CAUSE SOLUTION

The machine does not start (All the LEDs of the

buttons are off).

Master switch open. Close the switch.

Incorrect power supply. Check power supply and that the power cord is

plugged in

Electrical anomaly or blown fuses Contact the technician

1

.

The machine is on, but the temperature in the

tank does not drop.

Machine in off. Press the ON-OFF key until both LEDs light up.

Lack of refrigerant in the cooling system Contact the technician

1

.

Wrong thermostat temperature Adjust the storage temperature on lower values (see

chapt. III/3.6).

Dirty on the condenser Clean condensator with a brush

insufficient condensating Make sure that the machine is positioned at least 10

cm from walls or other obstacles and that the

operating parameters given in chapter II/3 are

respected.

Faulty fan Contact the technician

1

.

The product in the removable tank is frozen Wrong thermostat temperature Adjust the storage temperature on higher values (see

chapt. III/3.6).

The product comes out liquid Wrong pump regulation Turn the cream regulator to higher values (see chapt.

III/3.2).

Stuck non-return valve Wash the shutter and the non-return valve

(see chapt. IV/1 / IV/2).

Verify correct labyrinth assembly and wear

condition O-R

Assemble the components as described in section

IV/4.2, replace worn O-R if necessary.

Cream comes out slowly and it is too rich in air Wrong pump regulation Turn the cream regulator to lower values (see chapt.

III/3.2).

Wrong positioning of the suction tube Check that the suction tube is completely submerged

by the product in the removable tank.

The pump works, but no cream comes out of the

nozzle

Possible clogging of the circuit Make sure that all components are properly cleaned

and remove any residue if necessary.

Although the machine is on and the delivery

pushbutton is pressed, the pump does not start

up

Thermal protection intervention Wait a few seconds until the thermal relay is restored

(230V/50Hz/1, 115V/60Hz/1).

Dispensing does not end when the button is

released

Timed delivery mode active

If necessary, deactivate the timed delivery mode as

reported in chapter III/3.4.

1

= Queste operazioni devono essere eseguite solo ed esclusivamente da personale qualificato autorizzato.L’elenco dei centri assistenza tecnica

autorizzati è disponibile sul sito: www.frigomat.com/en/partners/world.

Il Costruttore declina ogni responsabilità per danni a cose o persone che possano verificarsi a causa dall’inosservanza di quanto sopra.

Loading...

Loading...