28

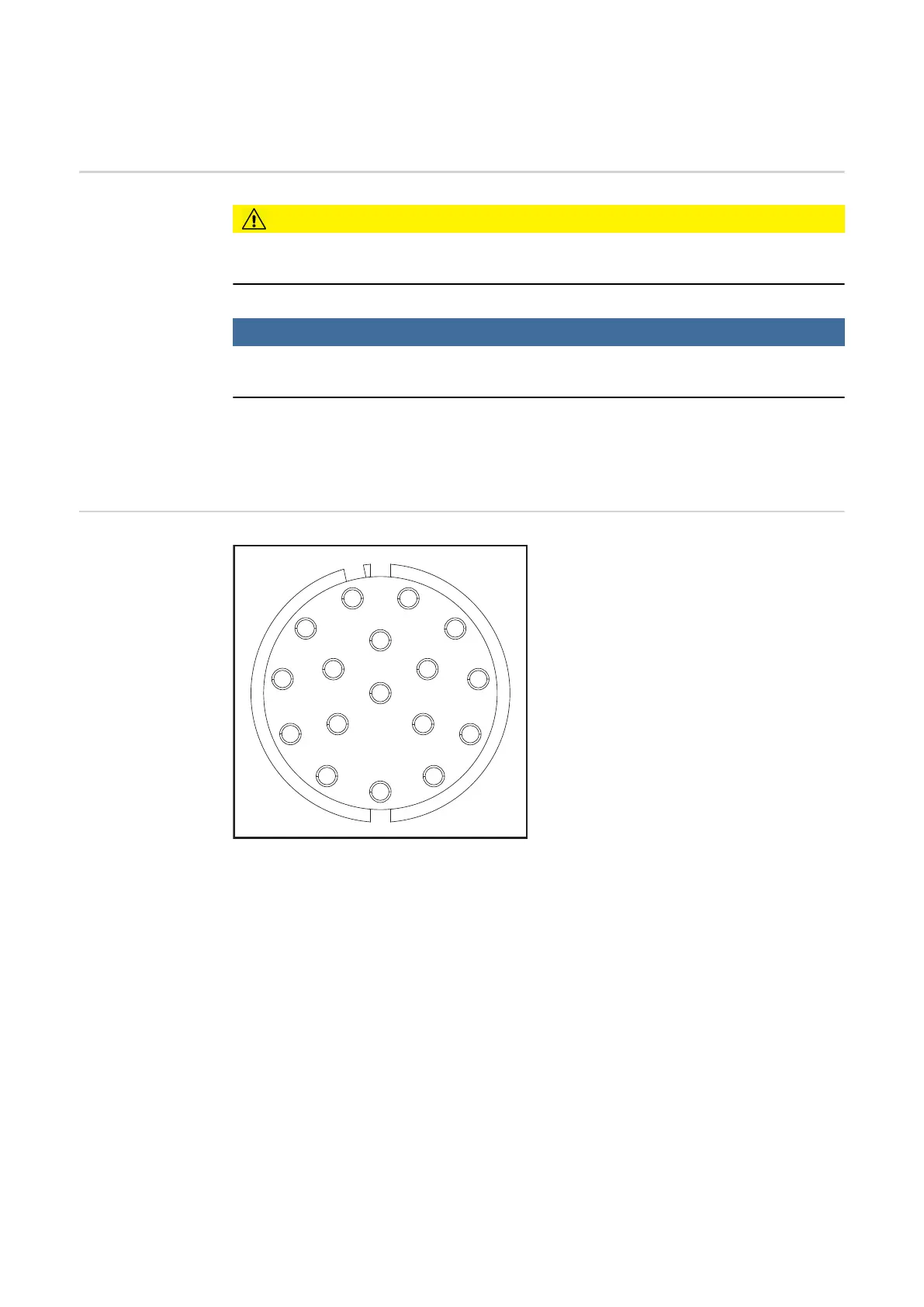

Standard I/O connecting plug (X1) pin assignment

for robot control

General

CAUTION!

Risk of damage to standard I/O connection (X1) supply due to overcurrent.

Secure supply against overcurrent with a 500 mA slow-blow fuse.

NOTE!

To avoid malfunction, keep the cable length between the cleaning device and robot

control as short as possible.

The standard I/O (X1) connecting plug for connecting the cleaning device to the robot con-

trol is part of the scope of supply. The cable harness must be adapted to the connection

technology on the robot control.

Standard I/O (X1)

connecting plug

pin assignment

Standard I/O (X1) connecting plug pin assignment -

cable-end view

Input and output signals on the Robacta

Reamer V Twin:

1. Clamp gas nozzle/Cleaning motor ON

(cleaning cutter turning) input signal +

24 V DC

2. GND general

3. Cleaning motor UP input signal (clea-

ning cutter moves to cleaning position)

+ 24 V DC

4. Spray parting agent input signal + 24 V

DC

5. + 24 V DC (supply)

6. Gas nozzle free output signal

7. Gas nozzle clamped output signal

8. Not assigned

9. Parting agent level OK output signal

10. Cleaning motor lowered output signal (cleaning cutter in start position)

11. Cleaning motor raised output signal (cleaning cutter in cleaning position)

12. Cut wire electrode input signal + 24 V DC

13. Swivel mechanism left output signal

14. Swivel mechanism right output signal

15. Move swivel mechanism to the left input signal

16. Move swivel mechanism to the right input signal

17. Not assigned

1

2

11

10

9

8

7

6

5

4

3

12

13

14

15

16

17

Loading...

Loading...