En-5

•Install the air inlet grille for air circulation. The correct

temperature can not be detected.

Unit

Duct

(Field supply)

Outlet Grille

(Field supply)

Inlet Grille

(Field supply)

(Room)

•Besuretoinstalltheairlterintheairinlet.Iftheairlter

isnotinstalled,theheatexchangermaybecloggedand

its performance may decrease.

4. PIPE INSTALLATION

]

CAUTION

•Bemorecarefulthatforeignmatter(oil,water,etc.)does

not enter the piping than with refrigerant R410A models.

Also, when storing the piping, securely seal the openings

by pinching, taping, etc.

•Whileweldingthepipes,besuretoblowdrynitrogengas

through them.

]1

4.1. Selecting the pipe material

CAUTION

•Donotuseexistingpipes.

•Usepipesthathavecleanexternalandinternalsides

without any contamination which may cause trouble

duringuse,suchassulfur,oxide,dust,cuttingwaste,oil,

or water.

•Itisnecessarytouseseamlesscopperpipes.

Material:Phosphordeoxidizedseamlesscopperpipes

It is desirable that the amount of residual oil is less than

40 mg/10 m.

•Donotusecopperpipesthathaveacollapsed,

deformed, or discolored portion (especially on the interior

surface).Otherwise,theexpansionvalveorcapillarytube

may become blocked with contaminants.

•Improperpipeselectionwilldegradeperformance.Asan

air conditioner using R410A incurs pressure higher than

when using conventional refrigerant, it is necessary to

choose adequate materials.

• ThicknessesofcopperpipesusedwithR410Aareasshown

in the table.

• Neverusecopperpipesthinnerthanthoseindicatedinthe

table even if they are available on the market.

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter [mm (in.)] Thickness [mm]

6.35 (1/4) 0.80

9.52 (3/8) 0.80

12.70 (1/2) 0.80

15.88 (5/8) 1.00

19.05 (3/4) 1.20

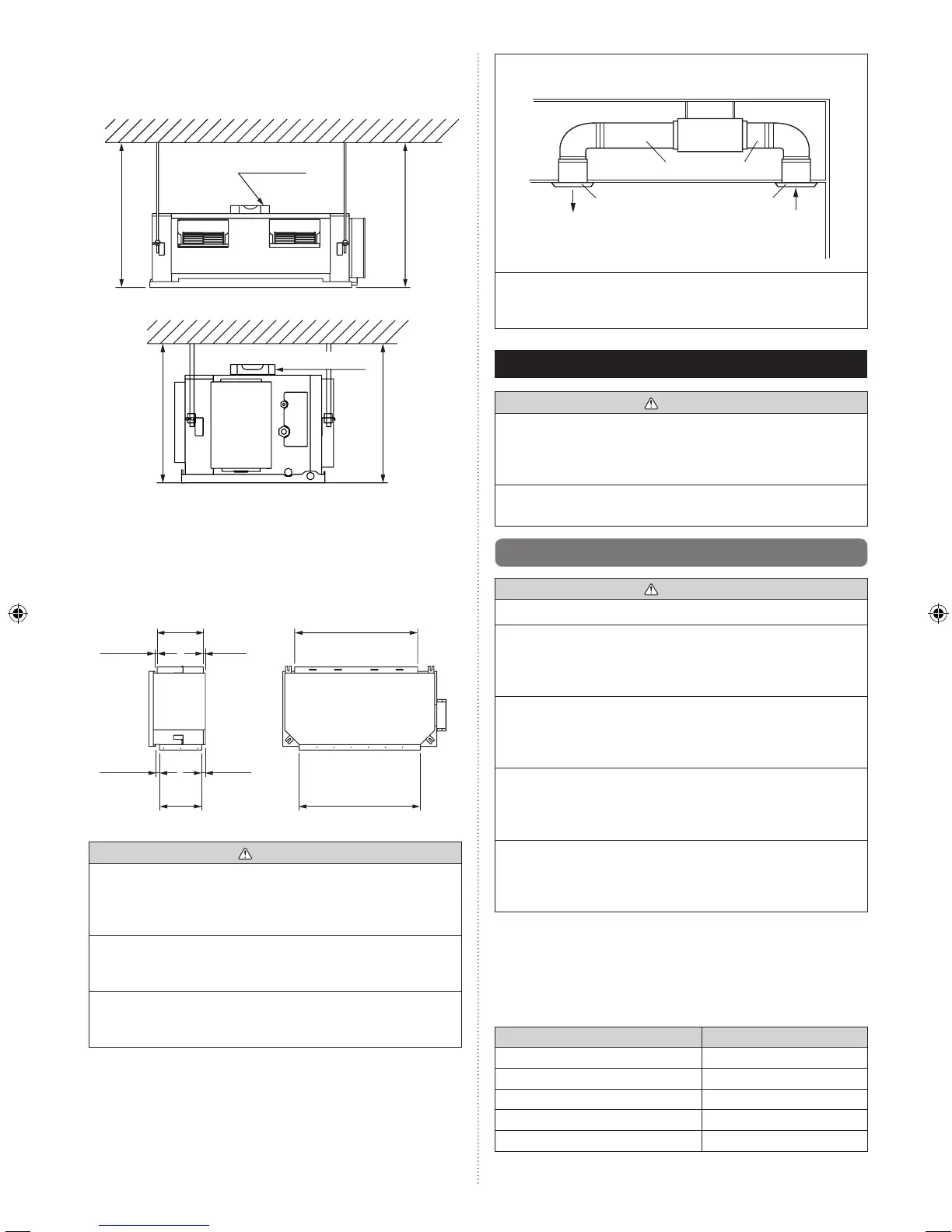

3.3.2. Leveling

Usetheprocedureinthefollowingguretoadjustthe

levelness.

AB

(Front)

Level meter

B A

Level meter

(Side)

The side A of the unit with the drain port should be slightly

lower than the opposite side B of the unit. The height

difference between sides A and B should be from 0 to 20 mm.

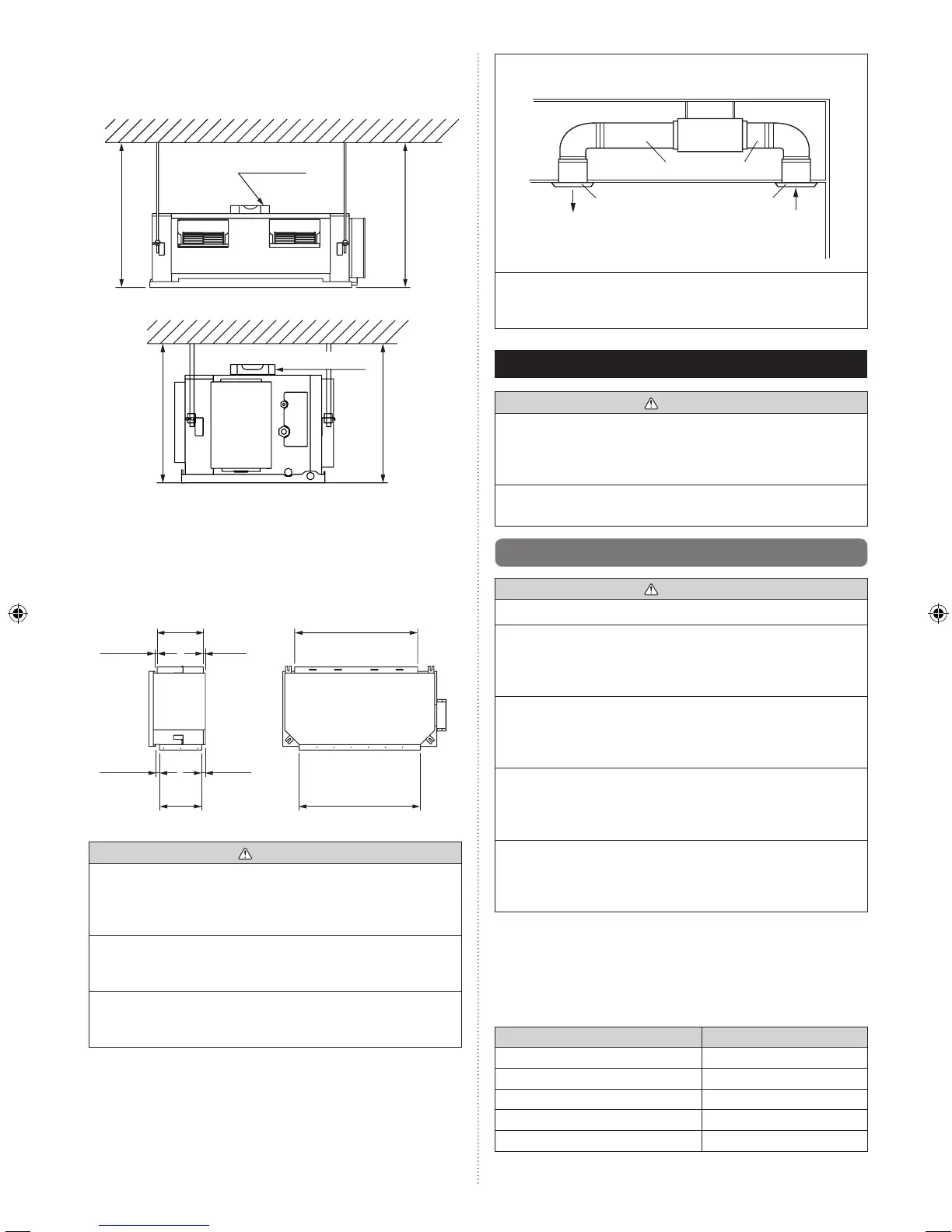

3.3.3. Mounting the duct

Followtheprocedureinthefollowingguretoinstalltheducts.

862 mm

Intakeportange

851 mm

14 mm

324 mm

∗

14 mm

∗

Spacingbetweenangeanddrainpan.

Outletportange

26 mm

295 mm

∗

27 mm

CAUTION

•Topreventpeoplefromtouchingthepartsinsidetheunit,

be sure to install grilles on the inlet and outlet ports. The

grilles must be designed in such a way that cannot be

removed without tools.

•Thestaticpressureoutsidetheunitisasfollows.

ARXC36LModel:100-200Pa

ARXC45/60LModels:100-250Pa

•Ifanintakeductisinstalled,takecarenottodamagethe

temperature sensor (the temperature sensor is attached

totheintakeportange).

Loading...

Loading...