En-6

1

4.2. Pipe requirement

CAUTION

•Refer to the Installation Manual of the outdoor unit

for description of the length of connecting pipe or for

difference of its elevation.

Use pipe with water-resistant heat insulation.•

CAUTION

•Install heat insulation around both the gas and liquid

pipes. Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 120 °C.

(Reverse cycle model only)

In addition, if the humidity level at the installation location

oftherefrigerantpipingisexpectedtoexceed70%,

install heat insulation around the refrigerant piping.

Iftheexpectedhumiditylevelis70-80%,useheat

insulationthatis15mmorthickerandiftheexpected

humidityexceeds80%,useheatinsulationthatis20

mm or thicker. If heat insulation is used that is not as

thickasspecied,condensationmayformonthesurface

of the insulation.

In addition, use heat insulation with heat conductivity of

0.045W/(m·K)orless(at20°C).

1

4.3. Flare connection (pipe connection)

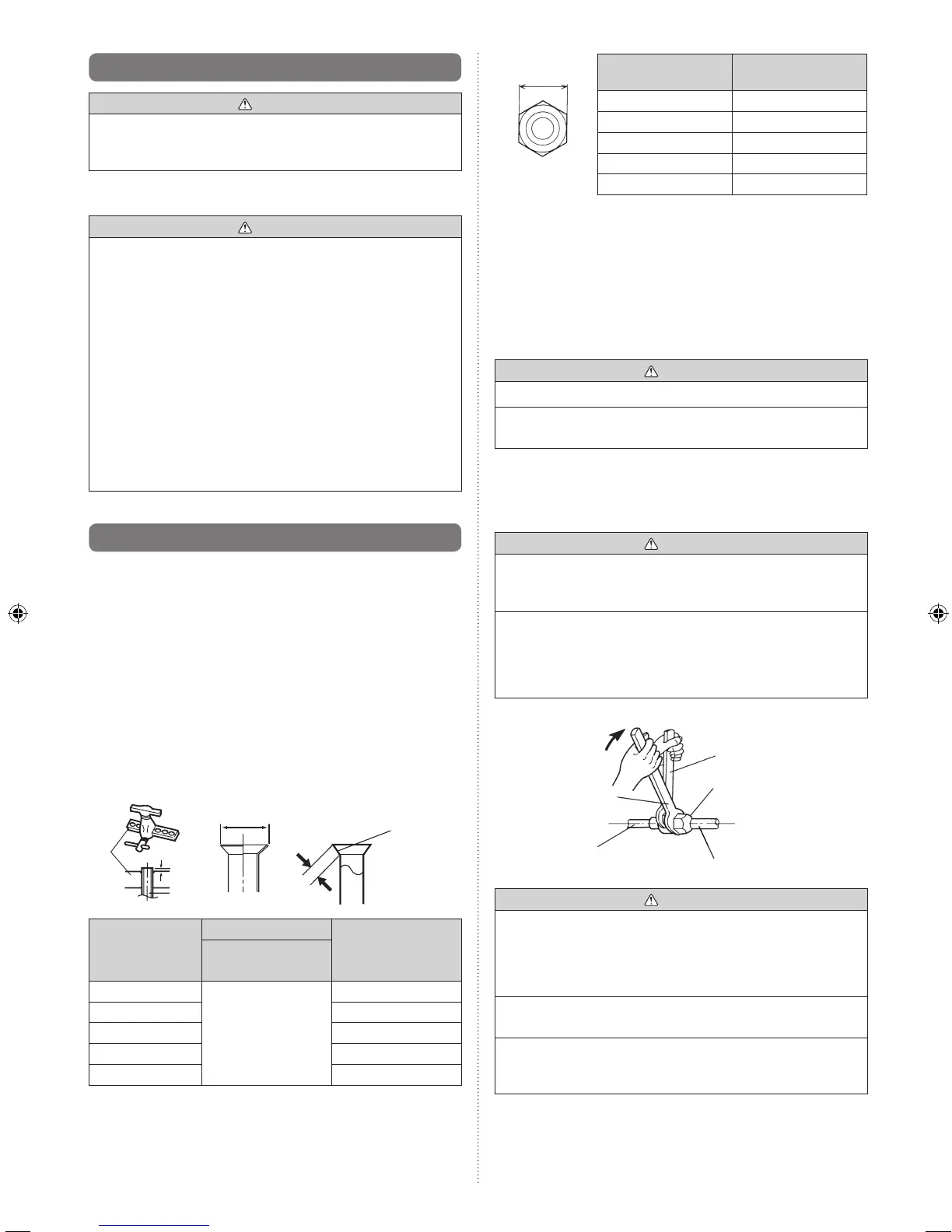

4.3.1. Flaring

• UsespecialpipecutterandaretoolexclusiveforR410A.

(1) Cut the connection pipe to the necessary length with a

pipe cutter.

(2) Hold the pipe downward so that cuttings will not enter the

pipe and remove any burrs.

(3) Insertthearenut(alwaysusethearenutattachedto

the indoor and outdoor units respectively) onto the pipe

andperformtheareprocessingwithaaretool.Usethe

specialR410Aaretool,ortheconventionalaretool.

Leakageofrefrigerantmayresultifotherarenutsare

used.

(4) Protect the pipes by pinching them or with tape to prevent

dust, dirt, or water from entering the pipes.

Checkif[L]isareduniformly

and is not cracked or scratched.

Die

Pipe

A

B

Pipe outside

diameter

[mm (in.)]

Dimension A [mm]

Dimension B

-

0

0.4

[mm]

Flare tool for R410A,

clutch type

6.35 (1/4)

0 to 0.5

9.1

9.52 (3/8) 13.2

12.70 (1/2) 16.6

15.88 (5/8) 19.7

19.05 (3/4) 24.0

WhenusingconventionalaretoolstoareR410Apipes,

thedimensionAshouldbeapproximately0.5mmmore

thanindicatedinthetable(foraringwithR410Aaretools)

toachievethespeciedaring.Useathicknessgaugeto

measure the dimension A.

Pipe outside

diameter [mm (in.)]

Width across flats

of Flare nut [mm]

6.35 (1/4) 17

9.52 (3/8) 22

12.70 (1/2) 26

15.88 (5/8) 29

19.05 (3/4) 36

4.3.2. Bending pipes

The pipes are shaped by your hands or pipe bender. Be •

careful not to collapse them.

Donotbendthepipesinananglemorethan90°.•

When pipes are repeatedly bend or stretched, the material •

willharden,makingitdifculttobendorstretchthemany

more.Donotbendorstretchthepipesmorethanthree

times.

CAUTION

•Topreventbreakingofthepipe,avoidsharpbends.

•If the pipe is bent repeatedly at the same place, it will

break.

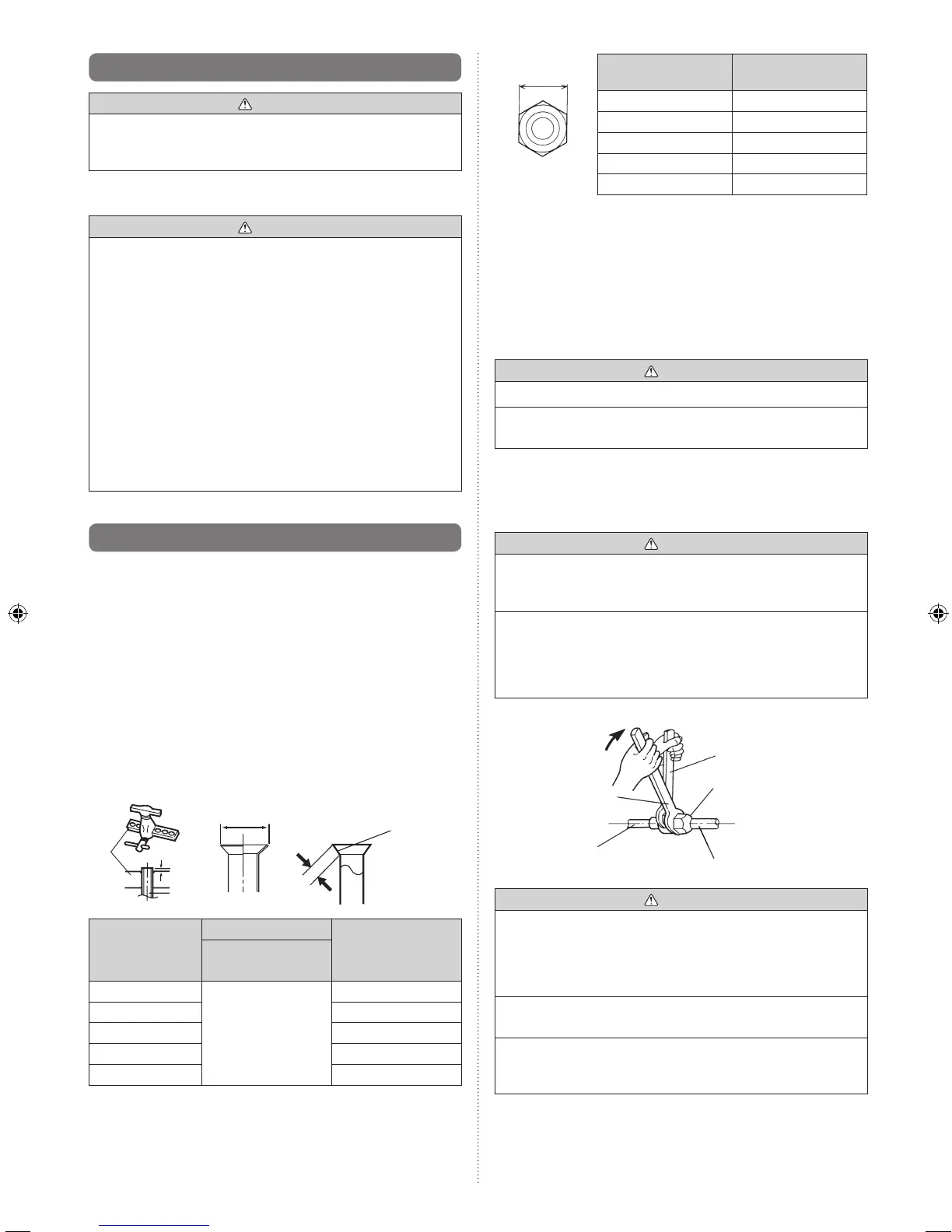

4.3.3. Pipe connection

Whenthearenutistightenedproperlybyyourhand,

hold the body side coupling with a separate spanner, then

tighten with a torque wrench.

CAUTION

•Holdthetorquewrenchatitsgrip,keepingitintheright

angle with the pipe, in order to tighten the flare nut

correctly.

•Tighten the flare nuts with a torque wrench using the

specified tightening method. Otherwise, the flare nuts

could break after a prolonged period, causing refrigerant

to leak and generate a hazardous gas if the refrigerant

comesintocontactwithaame.

Connection pipe

Torque wrench

Indoor unit pipe

(Body side)

Tighten with two wrenches.

Holding wrench

Flare nut

CAUTION

•Besuretoapplythepipeagainsttheportontheindoor

unit and the outdoor unit correctly. If the centering is

improper, the flare nut cannot be tightened smoothly.

If the flare nut is forced to turn, the threads will be

damaged.

•Donotremovethearenutfromtheindoorunitpipeuntil

immediately before connecting the connection pipe.

•Do not use mineral oil on flared part. Prevent mineral

oil from getting into the system as this would reduce the

lifetime of the units.

Width across

ats

Loading...

Loading...