En-9

CAUTION

•Groundtheunit.

Do not connect the ground cable to a gas pipe, water

pipe, lightning rod, or a telephone ground cable.

Improper grounding may cause electric shock.

•Donotconnectpowersupplycablestothetransmission

or remote control terminals, as this will damage the

product.

•Never bundle the power supply cable and transmission

cable together. Bundling these cables together will cause

miss operation.

•WhenhandlingPCB,staticelectricitychargedinthebody

may cause malfunction of the PCB. Follow the cautions

below:

•Establishagroundfortheindoorandoutdoorunitsand

peripheral devices.

•Cutpower(breaker)off.

•Touchmetalpartoftheindoorandoutdoorunitsfor

more than 10 seconds to discharge static electricity

charged in the body.

•Donottouchterminalsofpartsandpatterns

implemented on PCB.

]1

6.1. Electrical requirement

Voltage rating

230 V

Operating range

198 - 264 V

Recom-

mended cable

size (mm

2

)

Cable type Remark

Power

supply cable

2.5

Type245 IEC57

or equivalent

1ø 50 Hz

198 - 264 V

2 Cable + ground

Transmission

cable

0.33

LONWORKS

compatible cable

22 AWG

LEVEL 4 (NEMA)

non-polar 2 core,

twisted pair solid

core diameter

0.65 mm

Remote

control cable

0.33

Sheathed

PVC cable*

Polar 3 core

Twisted pair

*: Useshieldedcableinaccordancewithlocalrulesfor

remote control cable.

]1

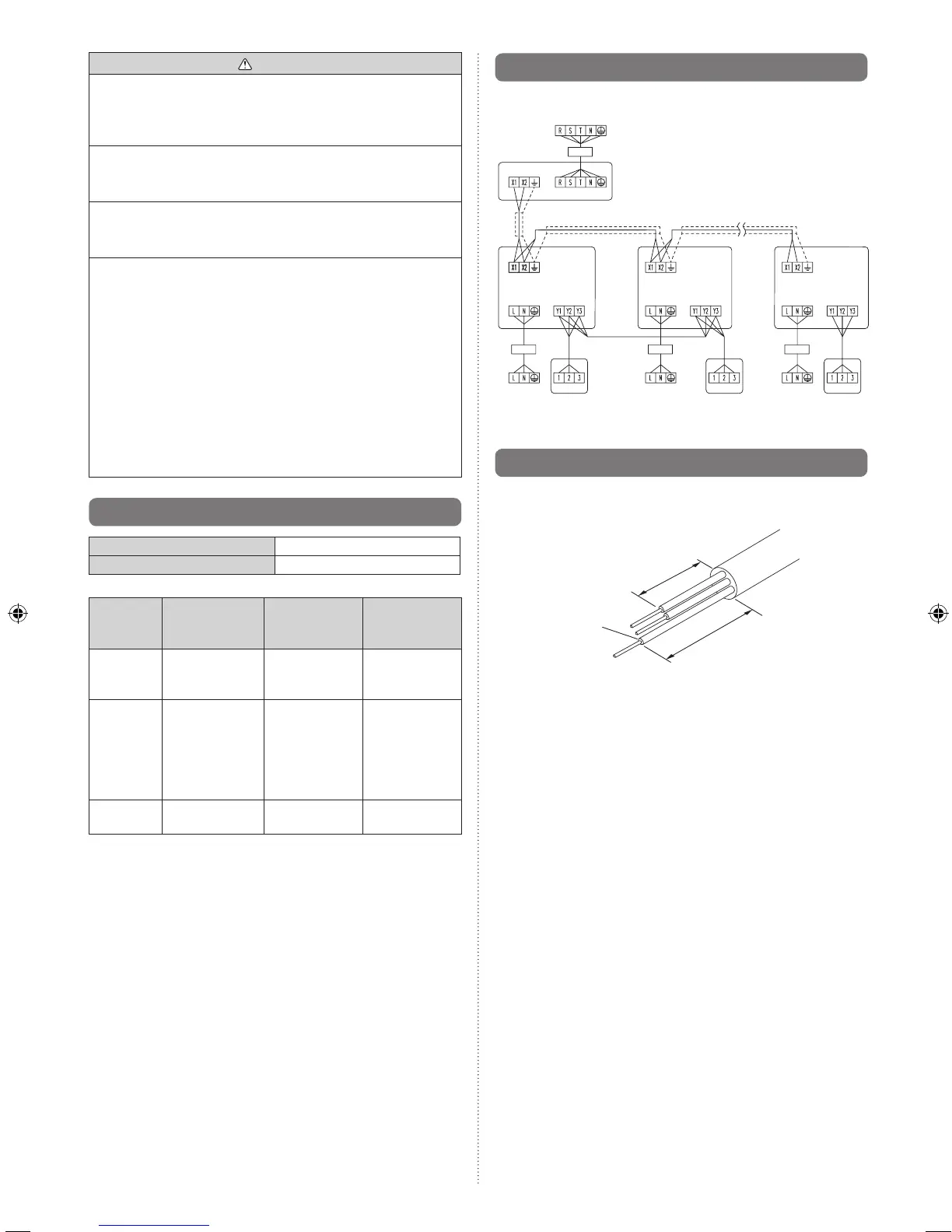

6.2. Wiring method

(EXAMPLE)

POWER SUPPLY

OUTDOORUNIT

BREAKER

POWER SUPPLY

TRANSMISSION

TRANSMISSION

POWER

SUPPLY

POWER

SUPPLY

REMOTE

CONTROL UNIT

(MASTER)

REMOTE

CONTROL UNIT

POWER

SUPPLY

REMOTE

CONTROL

TRANSMISSION TRANSMISSION

POWER

SUPPLY

POWER

SUPPLY

REMOTE

CONTROL

REMOTE

CONTROL

INDOORUNIT

POWER SUPPLY

REMOTE

CONTROL UNIT

(SLAVE)

INDOORUNIT

INDOORUNIT

BREAKER BREAKER BREAKER

]1

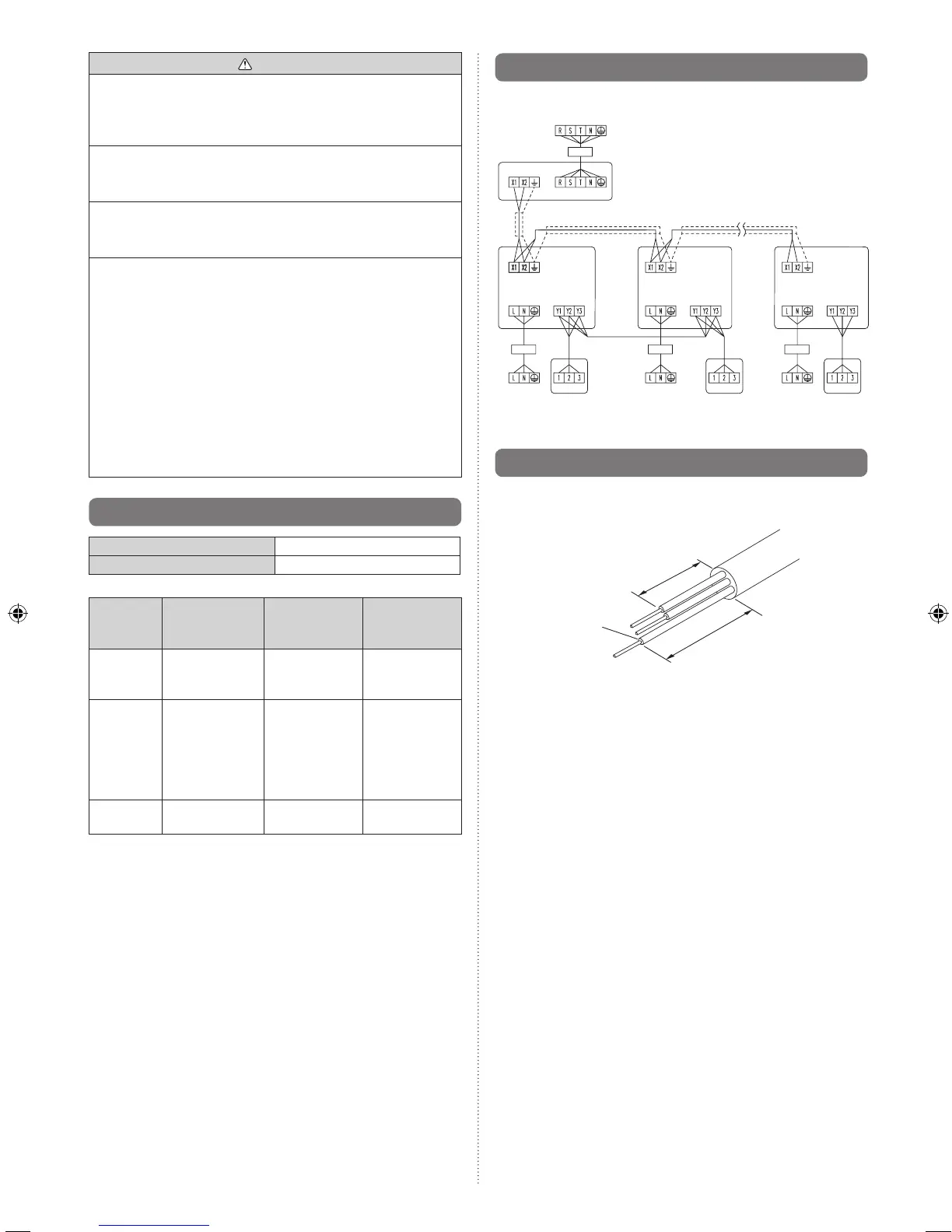

6.3. Unit wiring

• Beforeattachingthecabletoterminalblock.

6.3.1. Power supply cable

Power supply cable

20 mm

Earth cable

30 mm

A. For solid core wiring

(1) To connect the electrical terminal, follow the below

diagram and connect after looping it around the end of the

cable.

(2) Usethespeciedcables,connectthemsecurely,and

fasten them so that there is no stress placed on the

terminals.

(3) Use an appropriate screwdriver to tighten the terminal

screws.Donotuseascrewdriverthatistoosmall,

otherwise, the screw heads may be damaged and prevent

the screws from being properly tightened.

(4) Donottightentheterminalscrewstoomuch,otherwise,

the screws may break.

(5) See the table for the terminal screw tightening torques.

(6) Pleasedonotxtwopowersupplycableswithonescrew.

Loading...

Loading...