TI-30-Auto TDS Blowdown-2017-4

Systems that return for example very little condensate during the day, but a high proportion at night, are almost

impossible to control with any real accuracy. At best a compromise calibration will be achieved, where too much

blowdown at times may be the penalty.

When installing and

commissioning a new Automatic TDS Control Blowdown System, it must be

accepted that the calibration will be are iterative process, requiring continual sampling, testing, and re-

calibration until stable system operating conditions are achieved.

When purchasing an Automatic TDS Control Blowdown System from Fulton, the equipment would normally

be suppl

ied with the controller wired and fitted to the boiler control panel, with all the other parts supplied

loose for piping and wiring on site by others, unless agreed otherwise in our order acknowledgement.

The purchase price of the system supplied fully or part fitted includes for one single visit to commission the system

once installe

d. Part of the commissioning process will be the initial calibration of the TDS sensor to the water

conditions prevailing at the time.

Further re-calibration will be required until the water treatment regime has been established, and “typical”

water conditions have been achieved. Routine calibration checks will be required as part of the site

maintenance and water treatment monitoring.

The equipment and staff training required to carry out TDS sampling and calibration can be provided by Fulton. In

order to achieve the m

aximum benefit from the installation of an Automatic TDS Blowdown System, it is strongly

recommended that site personnel be provided with the necessary equipment, and training in order for them to fully

understand the function of the system, and the possible consequences of their actions.

Note: Where Automatic TDS Blowdown systems are provi

ded as part of a skid mounted or packaged plantroom

system, they will be fully installed piped and wired.

For further details on the installation

of Automatic TDS Controlled Blowdown Systems consult the Fulton Ltd

Technical Information Sheet 35. Automatic TDS Control Blowdown System Installation Guide.

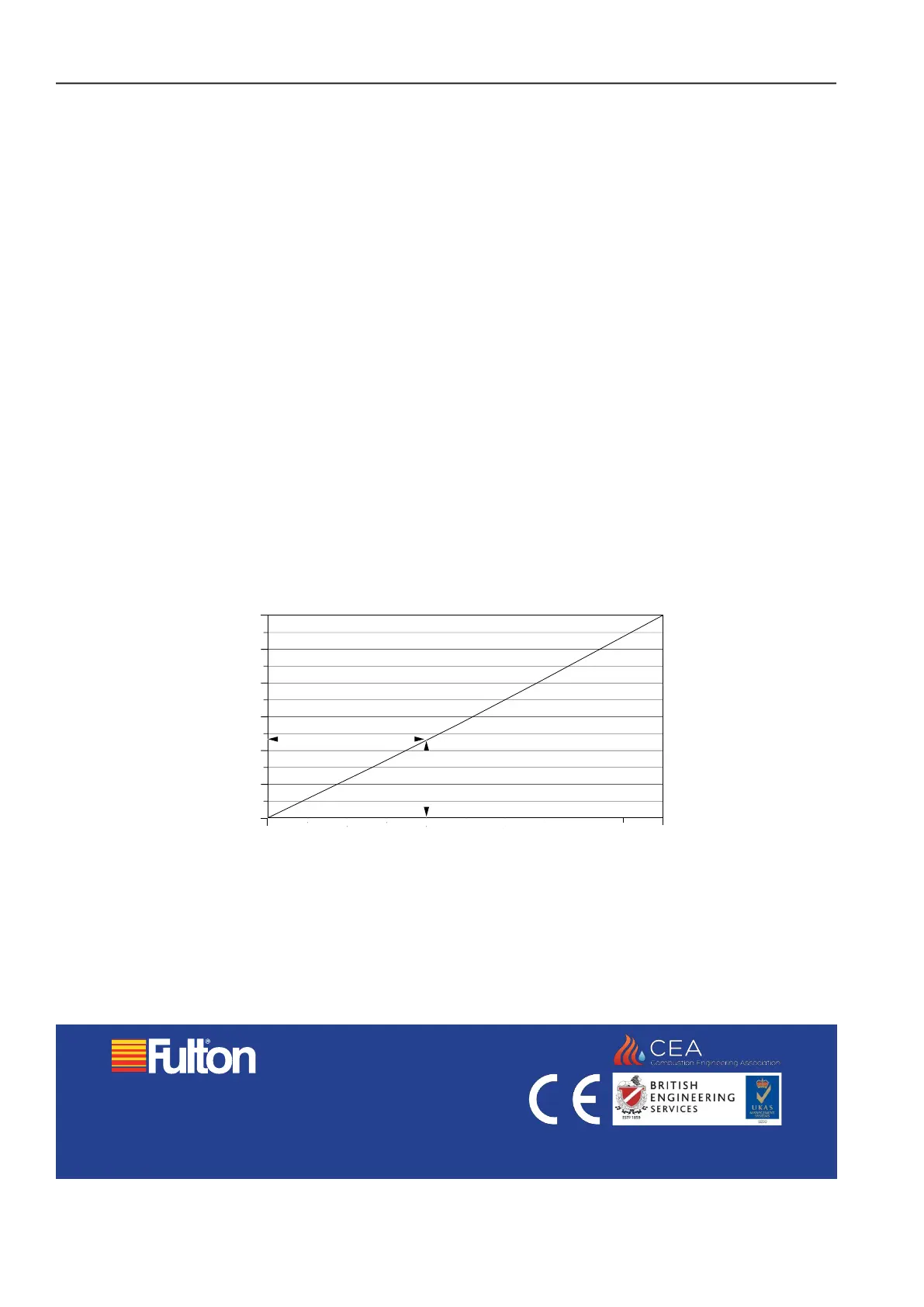

30

25

20

15

10

5

0

0 100 200 300 400 500

Feedwater TDS (ppm)

From Fig. 1.

%Blowdown required to maintain a boiler

TDS

of 2000 ppm against

feedwater TDS

Figure. 2 - TDS Graph 2

e.g. Hourly blowdown rate required to maintain a boiler TDS of 2000 with a feedwater TDS of 200 = 12%

For a 1000 kg/h boiler 120 kg/h (120 l/h) of blowdown is required.

Page 2 of 2

Every effort is made to ensure accuracy at time of going to press. However as part of our policy of continual product improvement, we reserve the right to alter specifications without prior notice.

Blowdown

(as a percentage of boiler output)

Fulton Ltd

Tel: +44 (0)117 972 3322

5 Fernhurst Road, Fishponds, Fax: +44 (0)117 972 3358

Bristol, BS5 7FG Email: sales@fulton.co.uk

England Website: www.fulton.co.uk

Loading...

Loading...