6.6 BOILER INTERNAL INSPECTION

The lower hand hole doors should be

removed after one month of operation

and the interior of the boiler thoroughly

examined. If scale or sludge build-up is

observed, it should be removed and

the water treatment supplier advised.

New gaskets must be fitted every time

a

hand hole door is removed (see

Section 6.7 - Fitting New Gaskets To

Boiler Inspection Holes).

Subsequent interior examinations

should be carried out on a regular

basis until satisfactory conditions are

observed. Thereafter, inspections

should be carried out at three monthly

intervals.

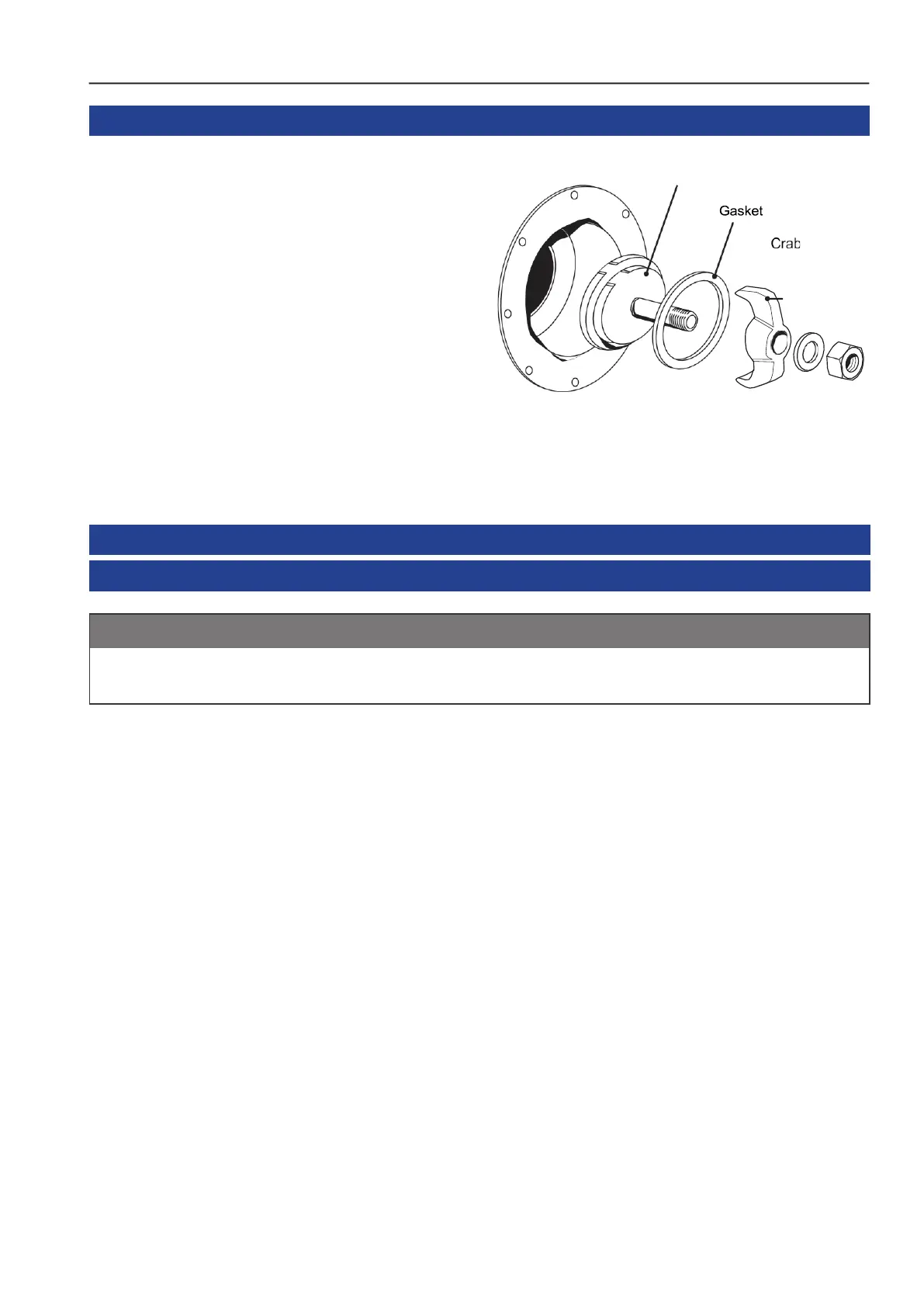

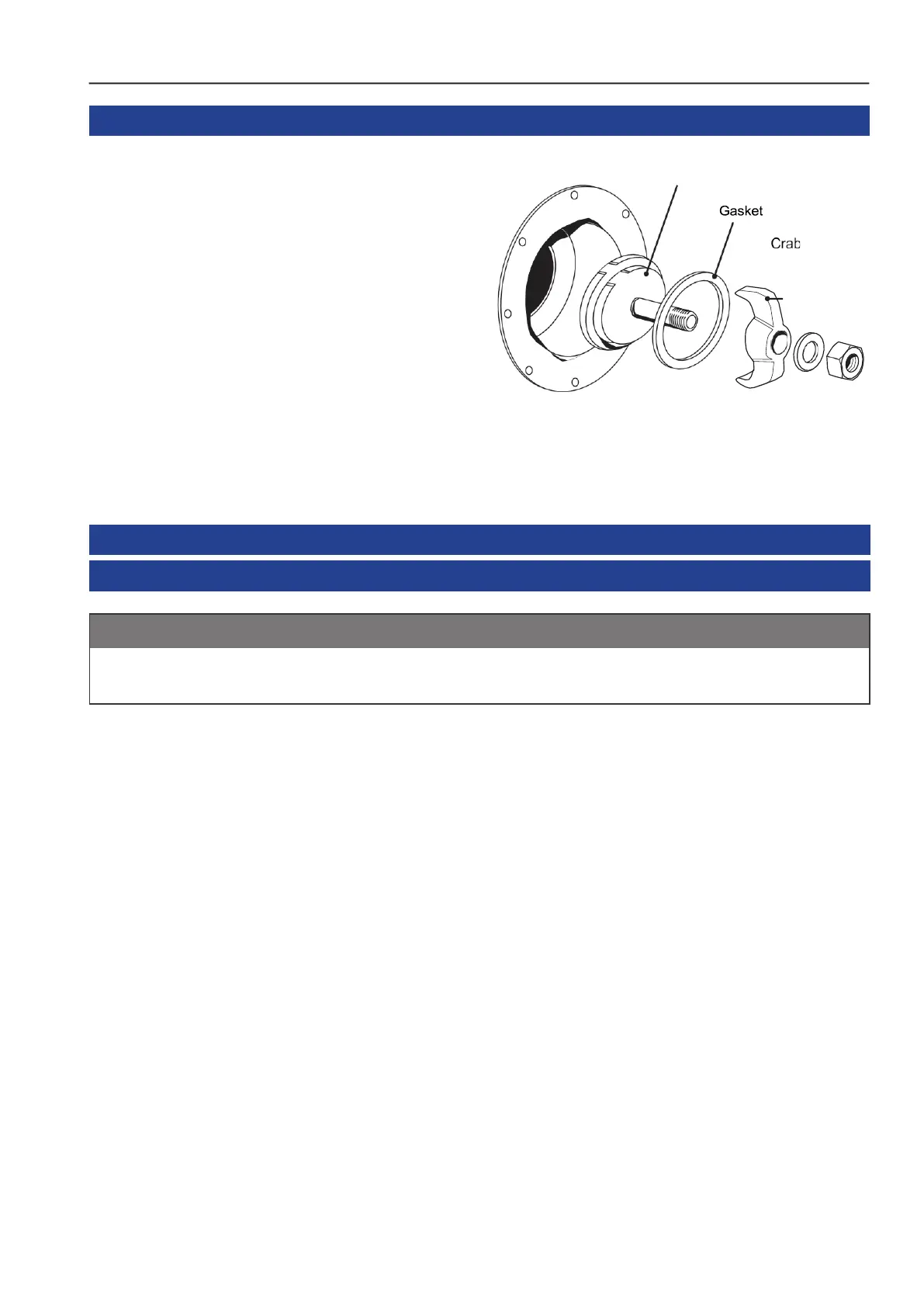

Hand Hole Cover Plate

Figure. 20 - Hand Hole

6.7 FITTING NEW GASKETS TO BOILER INSPECTION HOLES

6.7.1 IMPORTANT INFORMATION

TOPOG-E gasket have a finite life after installation and must be renewed annually.

It is important that the instructions given in this section are adhered to.

The VSRT boilers are fitted with TOPOG-E gaskets in all the steam and water side inspection

openings of the boiler. These gaskets work very well and millions have been safely used over

the last 30 years, however, it is absolutely essential to observe a few simple rules in order to get

the best performance from your installation.

Elastomeric Vulcanizates, which form the basis of TOPOG-E gaskets, undergo degradation

from many sources including heat, oxygen, stress, and overdosing from certain types of water

treatment. This takes the form of material oxidation, hardening/embrittlement and cracking which

may result in gasket failure. Steps must be taken to minimise the effects of such attacks.

Water treatment and oxygen attack can be minimised by ensuring that the gasket is aligned

correctly so that only the extreme edges of the gasket are exposed. If a new gasket leaks after

fitting this is almost certainly due to incorrect seating or alignment. As such gaskets are very

flexible it is possible to cure the leak by excessive tightening, but such an action will seriously

reduce the life of the gasket and cause problems later.

Undue stress can be avoided by tightening just sufficiently to stop any leakage when fitting cold

and

before firing the boiler. Start the boiler and gradually bring it up to working temperature,

allowing the increasing steam pressure to take over and complete the seal. This will allow the

gasket material to contract naturally and follow the topography of the mating surfaces. The

securing nut can then be tightened gently by approximately a quarter of a turn, to ensure a ‘snug’

fit and prevent the seal from being broken when the boiler is cold and under negative pressure.

Gentle warming of the boiler on initial firing after maintenance will also help to ensure that the

ru

bber ‘cures to shape’. If the rubber post-cures, the elastic memory will be destroyed and any

initial over tightening will cause the gasket to become hardened and embrittled, leading to cracks

and eventual failure.

Loading...

Loading...