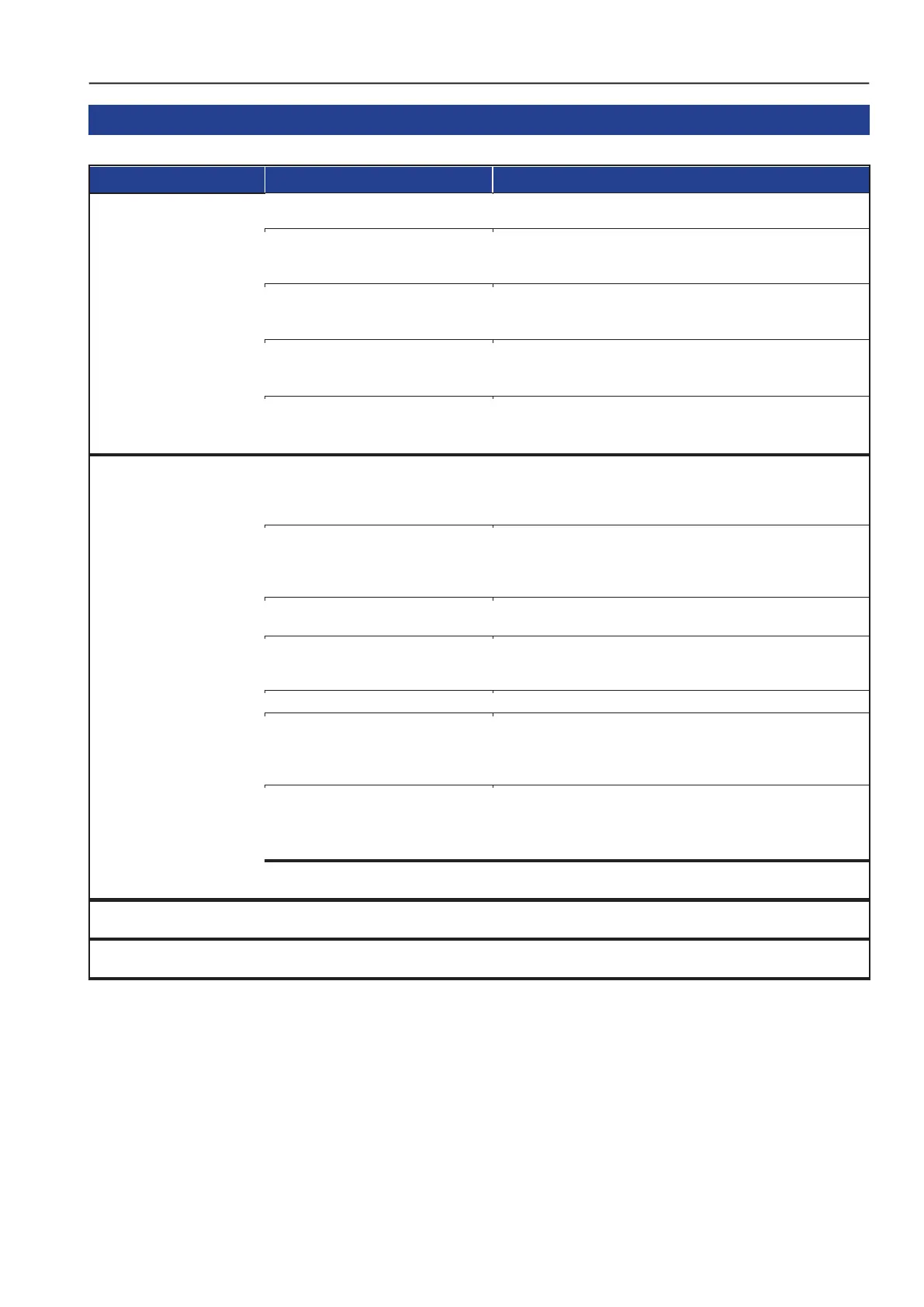

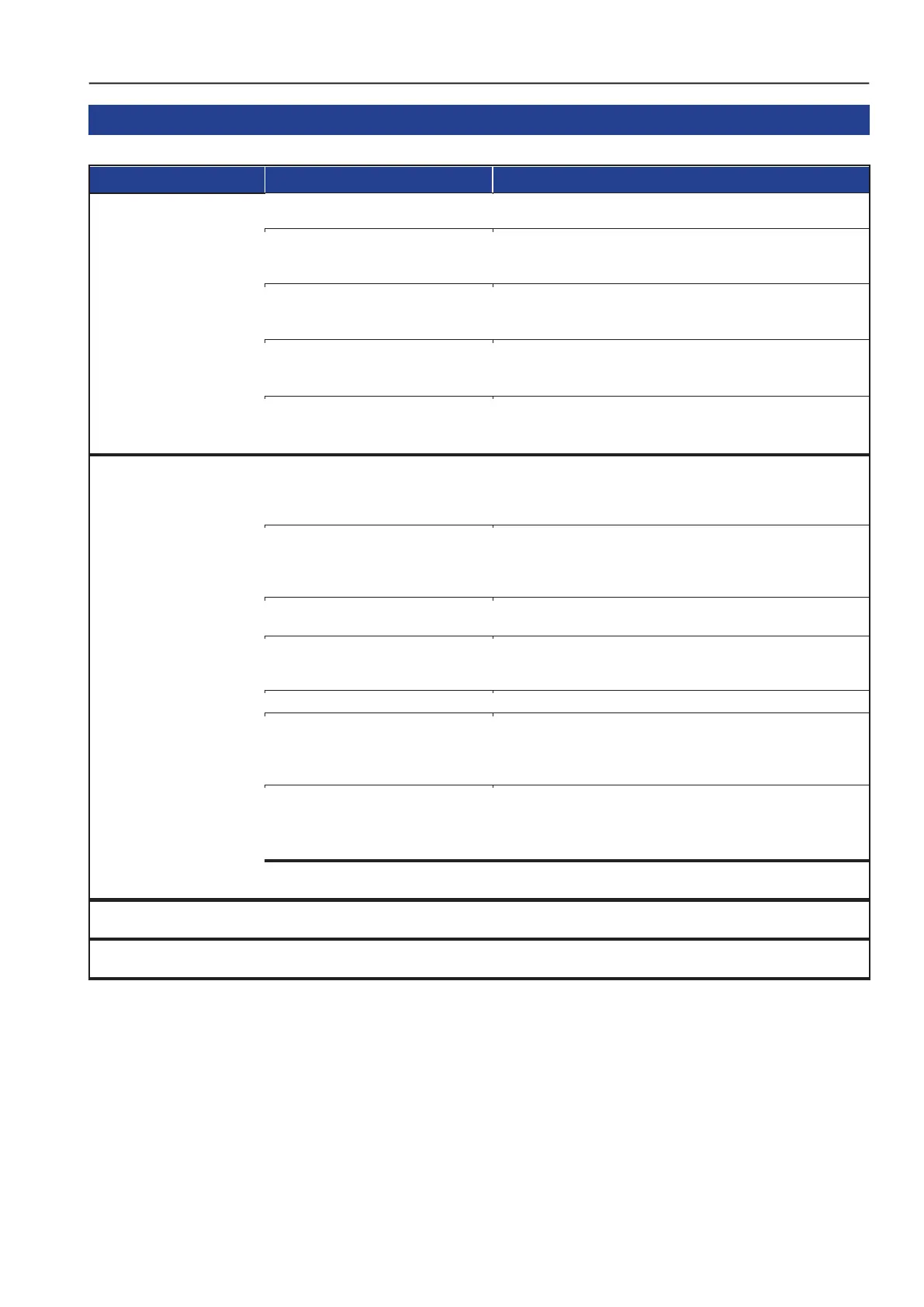

8.1 TROUBLESHOOTING GAS BOILER

Check air and gas servo motors and check CO2 and O2

combustion levels.

Check draft with a gauge. Draft should be -.05 to -.10 mbar

with the burner off, or -.10 to -.15 mbar when operating.

A barometric damper may need to be installed.

Check draft complies with min/max parameters

(Technical Data Sheet Appendix A).

4. Negative Room Pressure

Ensure there are no exhaust fans running in the boiler

room.

Check fan for obstructions, clean as required.

Check for cracks in porcelain, if found replace

the electrode. Check electrodes for carbon build-

up. Clean as required.

Check settings, adjust if required.

Check the detector is located correctly and clean.

Check draft complies with min/max parameters (Technical

Data Sheet Appendix A).

4. Negative room pressure

Ensure no exhaust fans are running in the boiler room.

Check Air servo motor operation and setting.

Check gas pressure coming into the gas train, if low

contact the gas supplier.

Check the setting on the gas valve regulator, adjust as

required.

Check flue Carbon build up and or obstruction.

Loading...

Loading...