37

If you see cracking in the part, bump the head temperature up 5 to 10

o

C. Do not exceed 305

o

C on the head. You

can also try printing slower and make sure the cooling blower is not running.

7.7.3 Model Issues

There are many issues that can be present in the STL files themselves that can cause problems with your prints.

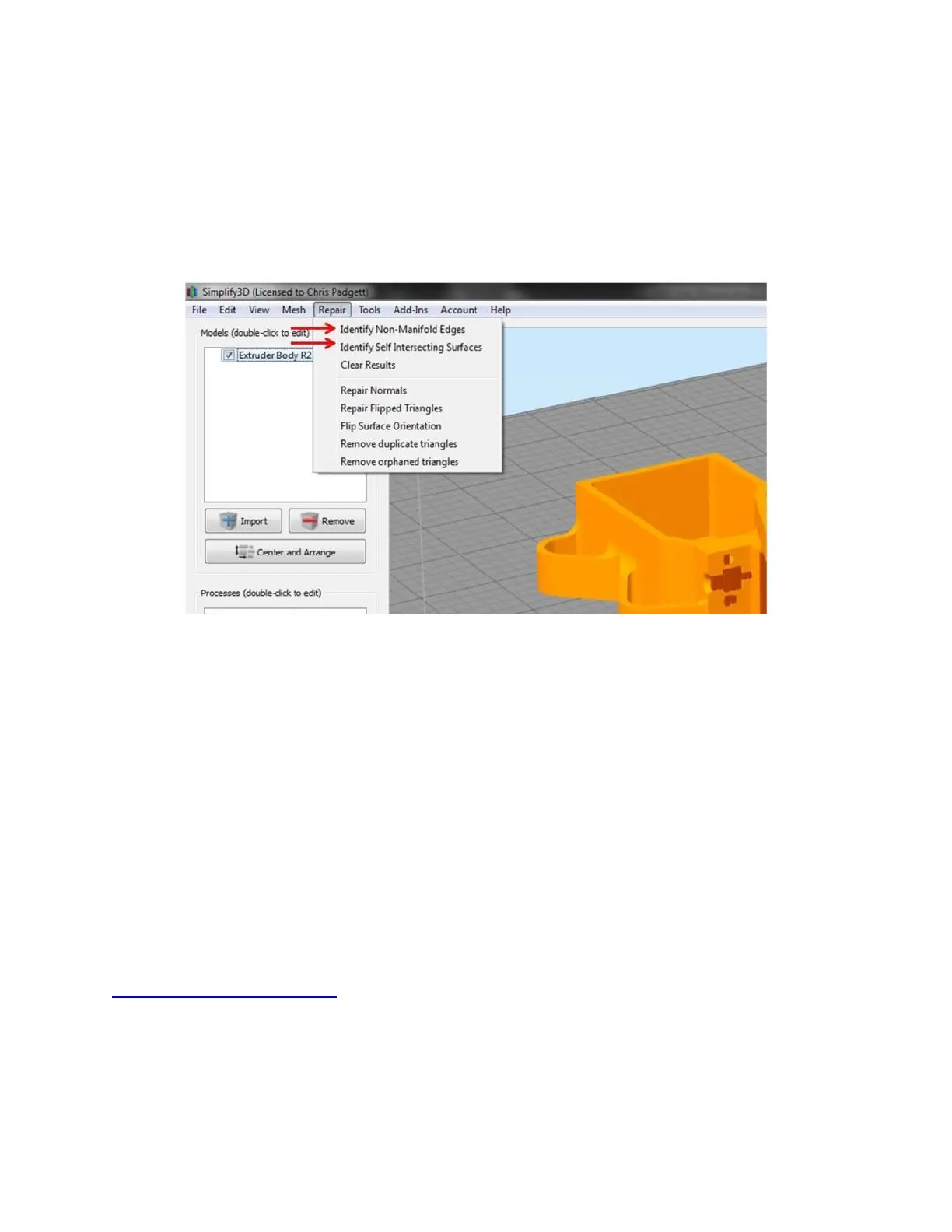

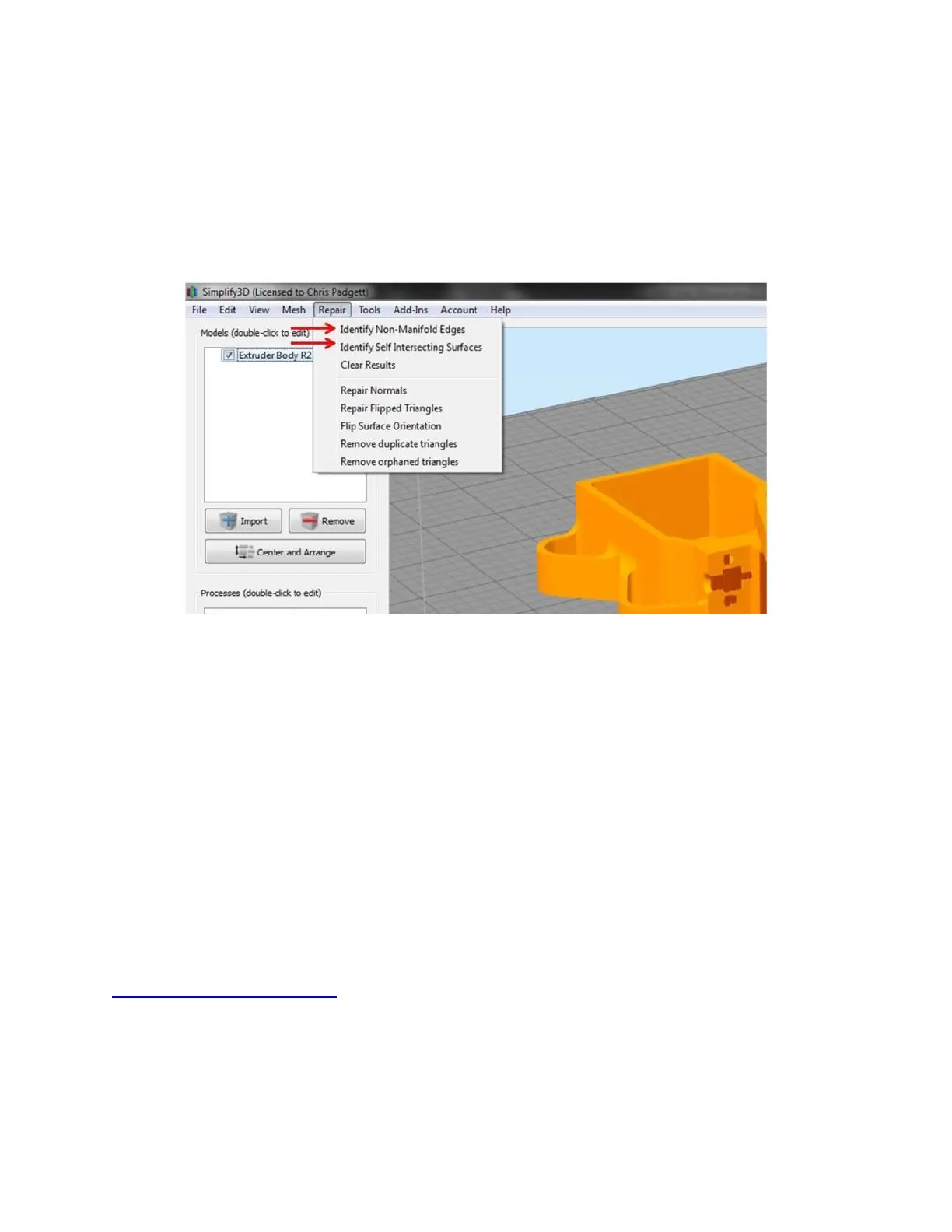

Simplify has some built-in ability to diagnose these problems. Under the “Repair” menu are two options to detect

issues.

In some cases, Simplify will be able to correctly slice the model anyway (it tries to make some assumptions about

what the part should look like) but it’s better to repair the file before attempting to slice it.

Other models may technically be “correct” STL files, but will still print poorly for some of the following reasons:

Internal geometry that is not needed

Not oriented properly (at a very slight angle)

Excessive number of faces

Zero thickness faces

When in doubt, preview the gcode and make sure it makes sense!

7.7.4 Repairing Models

While Simplify has some built-in options for repairing broken models, we’ve had the best luck with an online tool

called Netfabb cloud. This is a free service that will automatically repair any STL you upload and give you a fixed

version to download. You will need a Microsoft online account to use it.

https://netfabb.azurewebsites.net/

7.7.5 “Mystery Bridge” Layers

On some models you may see toolpaths generated that don’t match your model at all. Maybe there is a layer

where a hole is filled in (“bridged”), or maybe there are missing layers of gcode.

Loading...

Loading...