13-21-601 Page 32

Figure 4-3 – BLOWDOWN VALVE

Blowdown Valve (Figure 4-3 – BLOWDOWN VALVE) - This valve normally is used for control functions,

but also serves to relieve reservoir pressure following a shutdown. The blowdown valve is a two-way

solenoid valve which is piped into the oil reservoir outlet ahead of the minimum pressure valve. When the

solenoid is de-energized, the valve opens and the coolant system is blown down. When the solenoid is

energized, the valve closes to allow the coolant system to pressurize. A control air check valve is

provided to ensure that the inlet valve is closed during blowdown.

Oil Level Gauge (Figure 1-6, page 12) - This gauge is located on the oil reservoir and indicates the oil

level. See Section 5 for information on how to correctly read the gauge and proper lubrication.

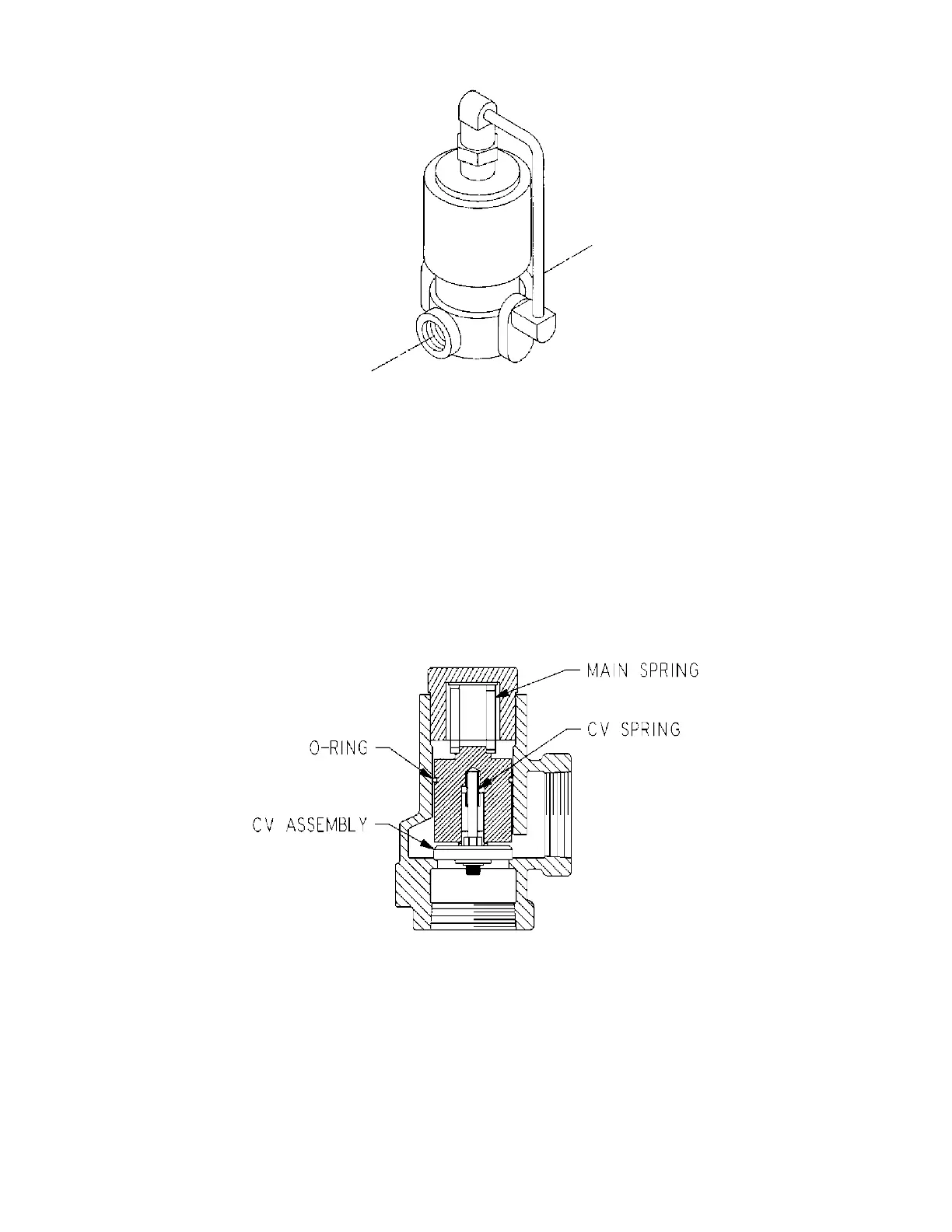

Figure 4-4 – MINMUM DISCHARGE PRESSURE/CHECK VALVE

Minimum Discharge Pressure/Check Valve (

Figure 4-4, page 32) - An internal spring-loaded minimum

pressure valve is used in the final discharge line to provide a positive pressure on the coolant system of

the compressor even if the air service valve is fully open to atmospheric pressure. This valve also

functions as a check valve to prevent back flow of air from the shop air line when the unit stops, unloads,

or is shut down.

Loading...

Loading...