1. Getting Started

DMS 2 Operating Manual Page 3

Step 4: If you select the AUTO zeroing procedure, the instru-

ment will zero the probe on its own. If instead you selected

manual zeroing, zero the instrument-probe combination by

using the following procedure.

• With the probe uncoupled (not touching any material),

press

.

• Couple the probe’s measurement surface (after applying

couplant) to the ZERO BLOCK on the front of the DMS 2.

• The instrument display will indicate when the zeroing

process is complete.

NOTE: Couplant must be used between the measurement

surfaces of all probes and the material being tested. Thickness

readings can not be obtained without the use of couplant.

Step 5: Determine the material velocity by performing a one-

point calibration. Note that while the default velocity setting

represents common steel (0.2313 × 10

6

inches per second),

you must calibrate the instrument to match the specific

material that you’re inspecting. In Step 3, you selected the dual

measurement mode. Most probes will allow you to perform a

one-point calibration and operate in this mode. See Sections

3.3.1 and 3.3.4 for additional calibration options. Otherwise,

use the following procedure to calibrate your instrument.

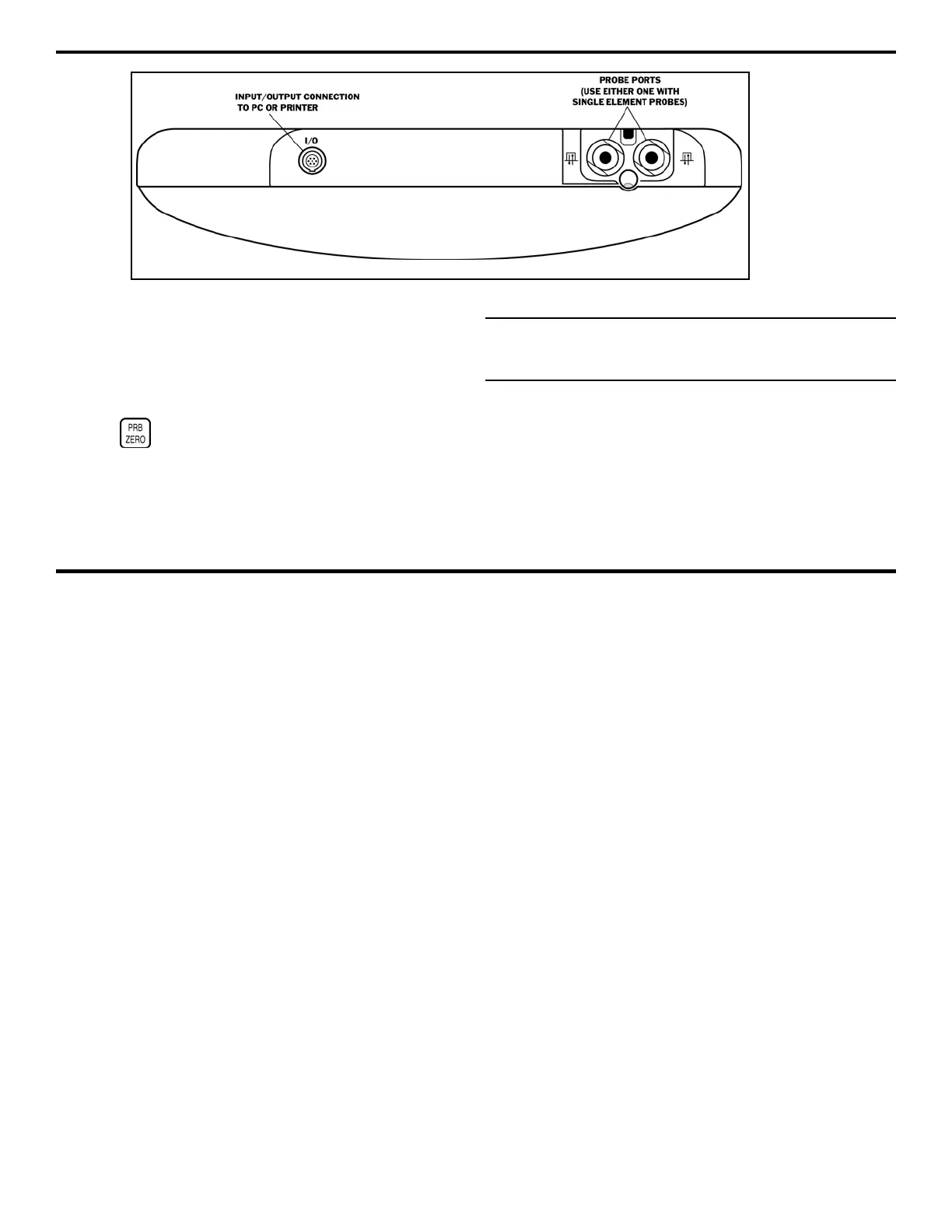

FIGURE 1-2—The instrument’s connectors are shown here.

Loading...

Loading...