GE Analytical Instruments ©2006 12-15 DLM 14291 Rev. A

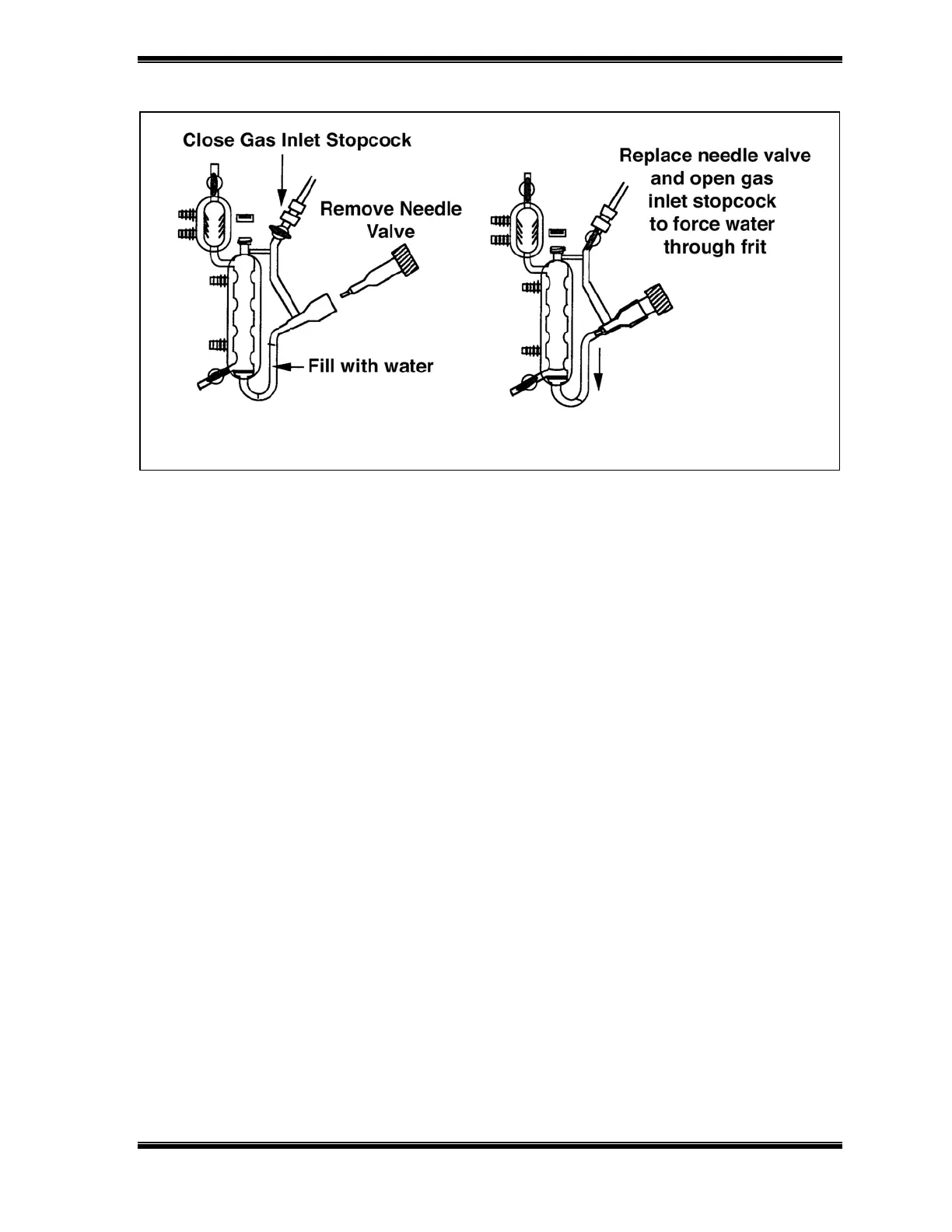

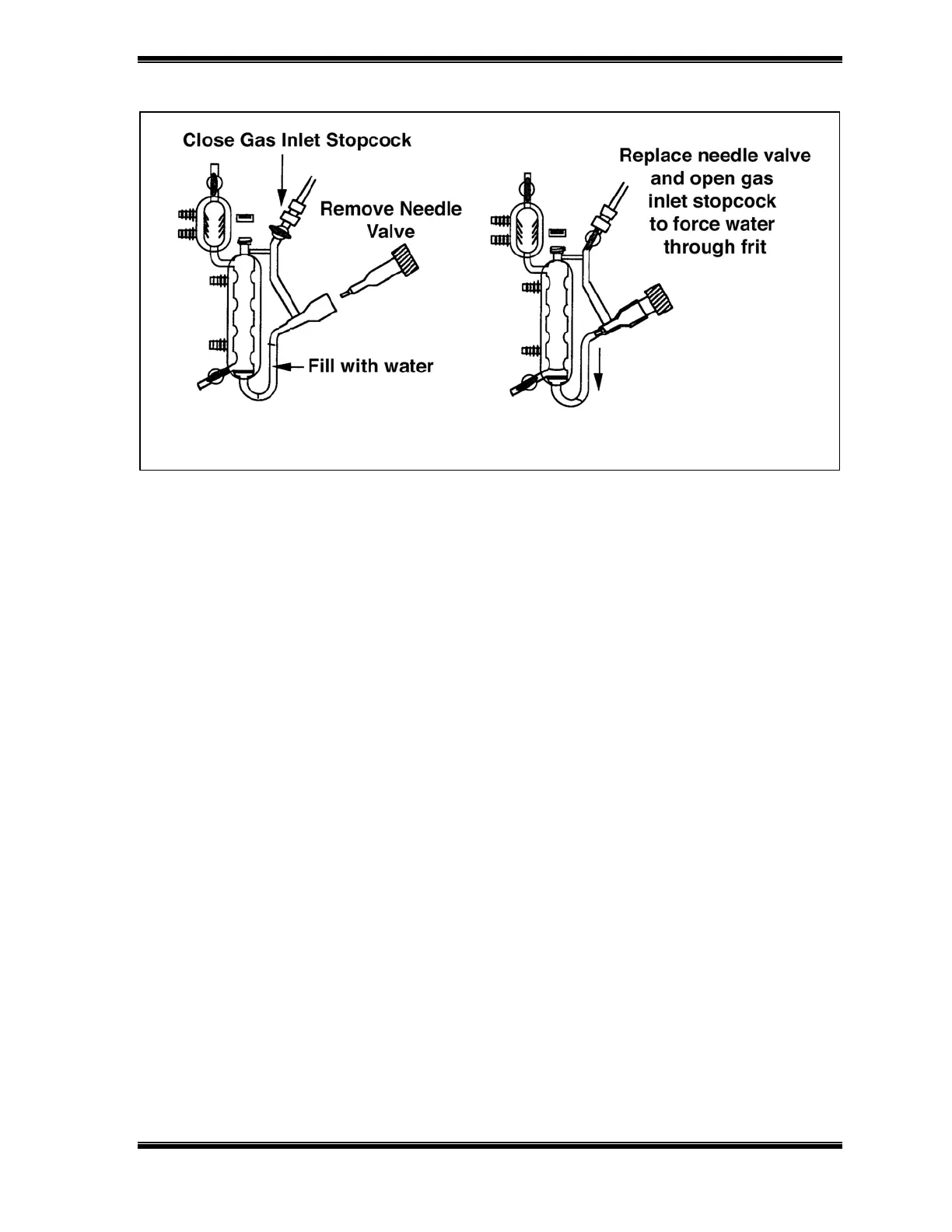

Figure 12-3: Cleaning the Purge Vessel Frit.

• If the condenser cannot be totally cleaned by rinsing, loosen the clamp so that

the purge vessel can be tilted. Fill the purge vessel with water then replace the

screw cap a few turns so that it is not tightly sealed, and will allow air to

escape. Tilt the purge vessel to fill of the condenser with water then return to

the upright position. Repeat until all of the contamination has been removed.

• To clean the frit, turn off the gas inlet stopcock and unscrew and remove the

needle valve on the purge vessel. Use a wash bottle or pipette to fill the glass

tube between the needle valve connection and the frit with water.

• Replace the needle valve, and open the gas inlet stopcock to allow the gas to

force the water through the frit. Once the water has been passed through the

frit, turn off the gas inlet stopcock, remove the needle valve, and add more

water to the tube. Replace the needle valve, and turn on the gas to force the

water through the frit. Repeat this procedure 3 or 4 times to completely clean

the frit and tubing.

• After cleaning the frit, replace the reducing union on the outlet of the purge

vessel. Tighten the 1/4" nut fingertight. Do not use a wrench to tighten the nut

because the glass will break if the nut is overtightened (see Procedure for

Tightening Swagelok Fittings page 11-4).

Loading...

Loading...