GE Analytical Instruments ©2006 8-6 DLM 14291 Rev. A

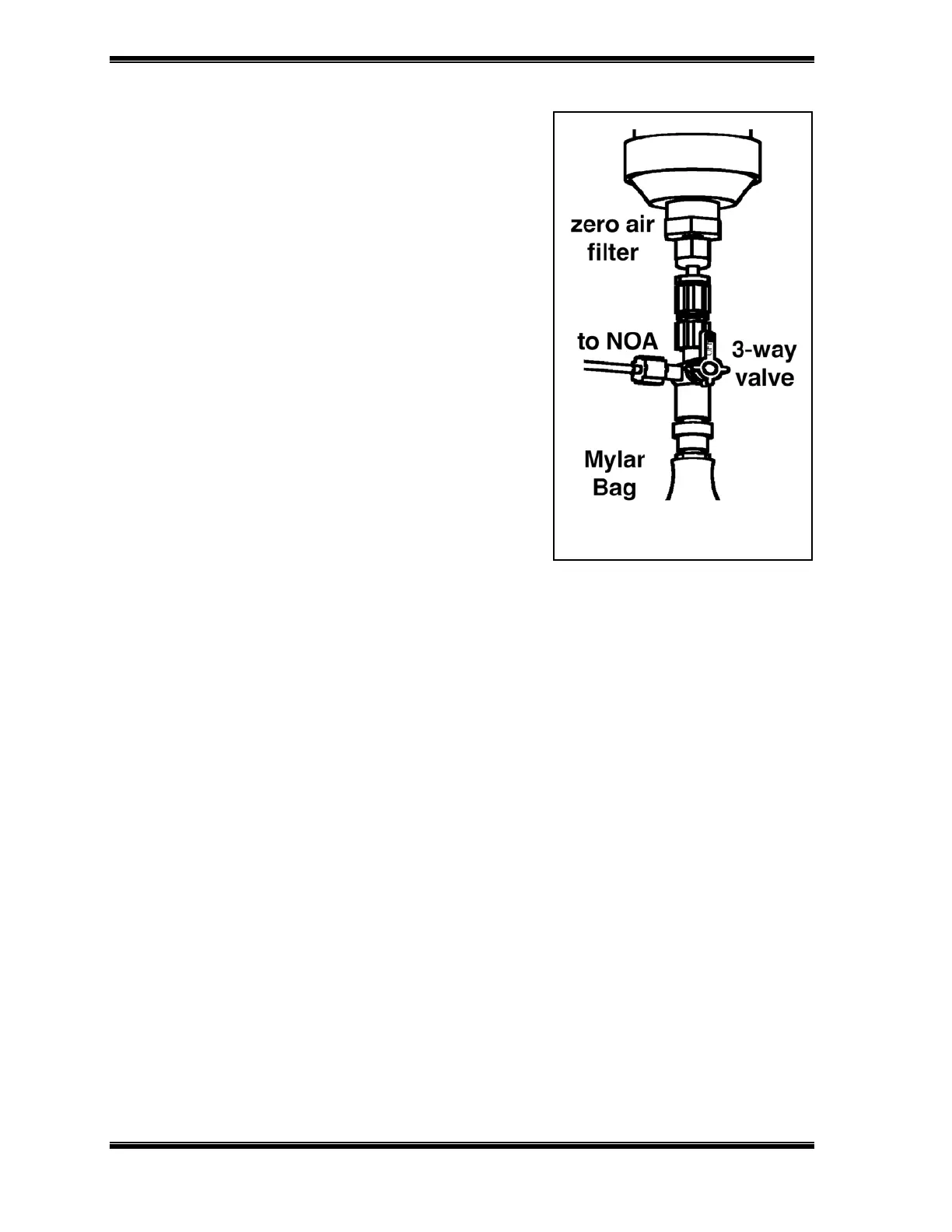

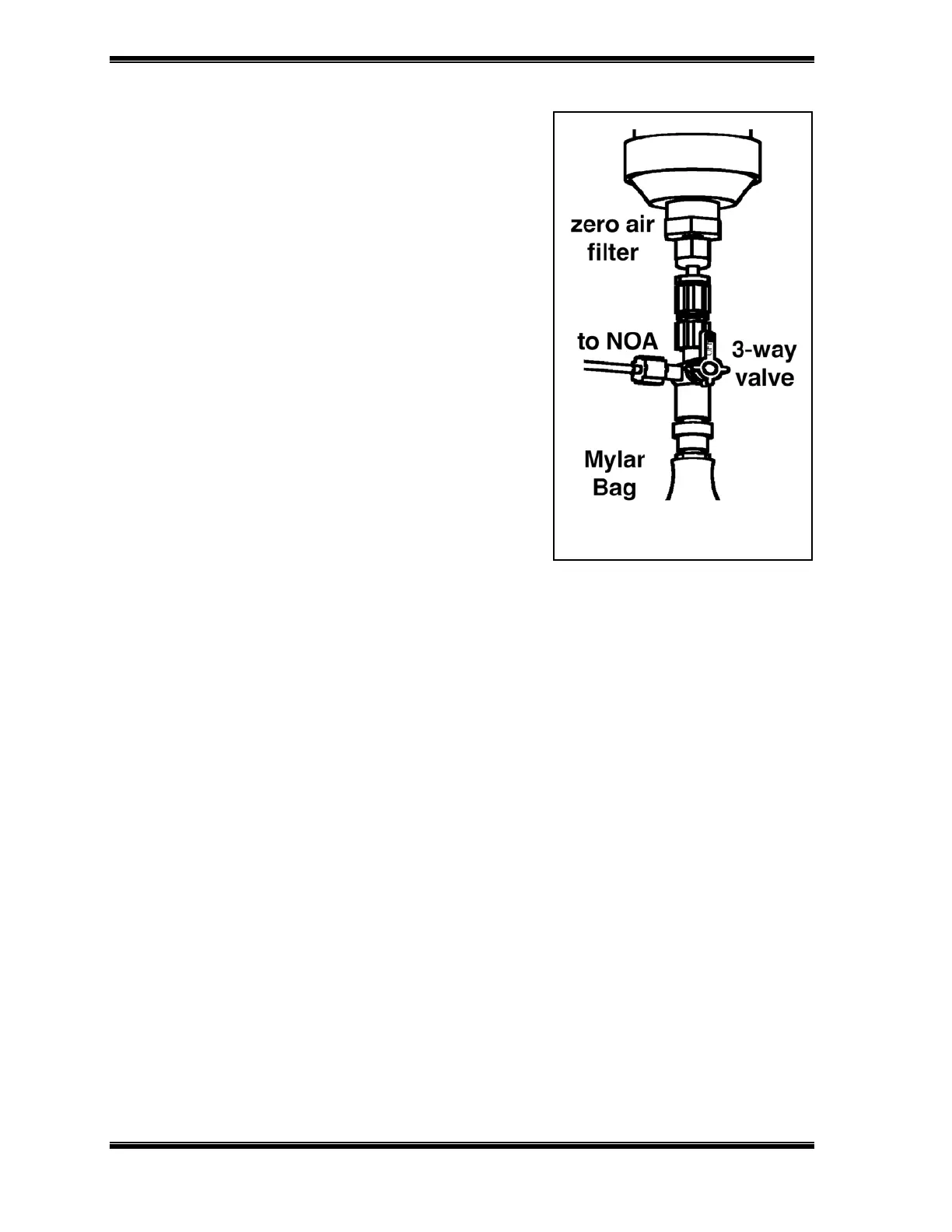

Figure 8-3: Setup for

Cleaning Bags.

and the final leg connected to the bag (Figure 8-

3). As outlined below, this setup allows zero air to

be drawn into the bag.

• Remove the frit restrictor from the NOA and

connect the Nafion drier directly to the NOA

sample inlet. With 3-way valve and zero air

filter connected to the NOA, turn the valve so

that OFF is positioned toward the Zero Air

Filter and allow the NOA to completely

evacuate the gas from the bag. Disconnect the

bag and repeat for the remaining bags.

• Connect the bag to a source of dry, low NO gas

and slowly fill the bag. It is not necessary to completely fill the bag.

• Reconnect the bag to the 3-way valve. Turn the valve so that OFF points

toward the zero air filter. Allow the NOA to completely evacuate the contents

of the bag.

• After the bag is evacuated, turn the 3-way valve so that OFF points toward the

sampling line connected to the NOA. This will allow gas from the zero air filter

to be drawn into the Mylar bag and bring the pressure inside the bag back to

atmospheric. Disconnect the bag, and seal the bag with the cap. Reposition the

3-way valve so that OFF points toward the Zero Air Filter. Repeat for remaining

bags. Store the bags in a clean, dry and secure location. Reinstall the

restrictor before using the NOA for gas analysis.

Bags cleaned by this procedure will remain low in NO for approximately 24 hours.

Collecting the Samples – Vital Capacity Bag Kit

Loading...

Loading...