Owner’s Manual for Snow Blower 23

Maintenance

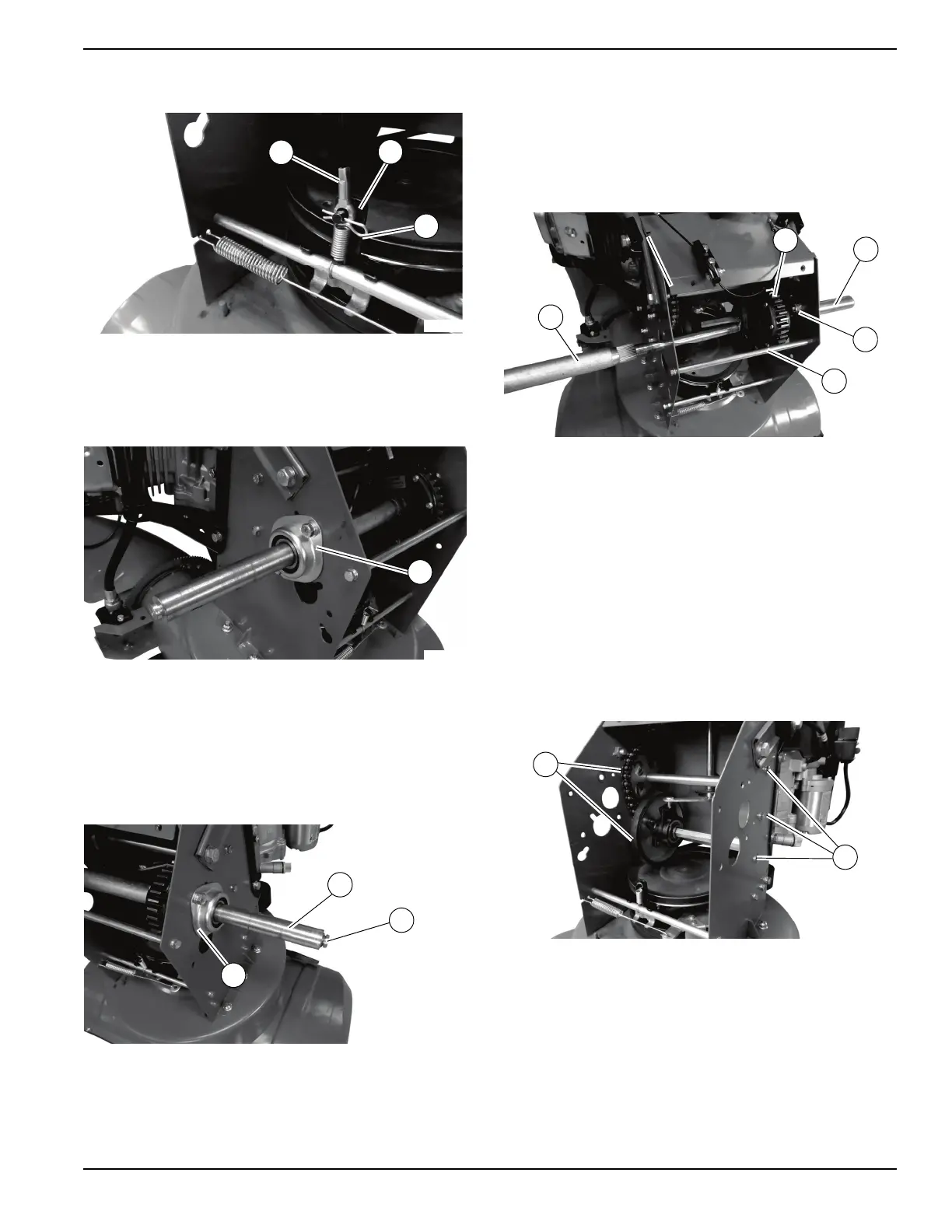

8. See Figure 4-23. Remove pin (I) and traction cable

(K) from traction drive bracket (J).

Figure 4-23. Removing Pin and Traction Cable

9. See Figure 4-24. Remove the two bolts, lock

washers, flat washers, and l

ocknuts securing left

side wheel bearing assembly (L) using two 13mm

wrenches.

Figure 4-24. Wheel Bearing Assembly

10. Remove bearing assembly

from axle.

11. See Figure 4-25. Hold the larger diameter outer

shaft (M) of the right-side axle shaft while hitting

the

smaller diameter inner shaft (N) with a dead

blow hammer. This will push the smaller shaft in,

separating it from the larger outer shaft.

Figure 4-25. Outer and Inner Shafts

NOTE: A

brass punch may be needed to push the

smaller diameter shaft in further to separate the two shaft

sections.

12. R

emove the two bolts, lock washers, flat washers,

and locknuts securing right side wheel bearing

assembly (O) using two 13mm wrenches. Remove

the bearing assembly from the axle.

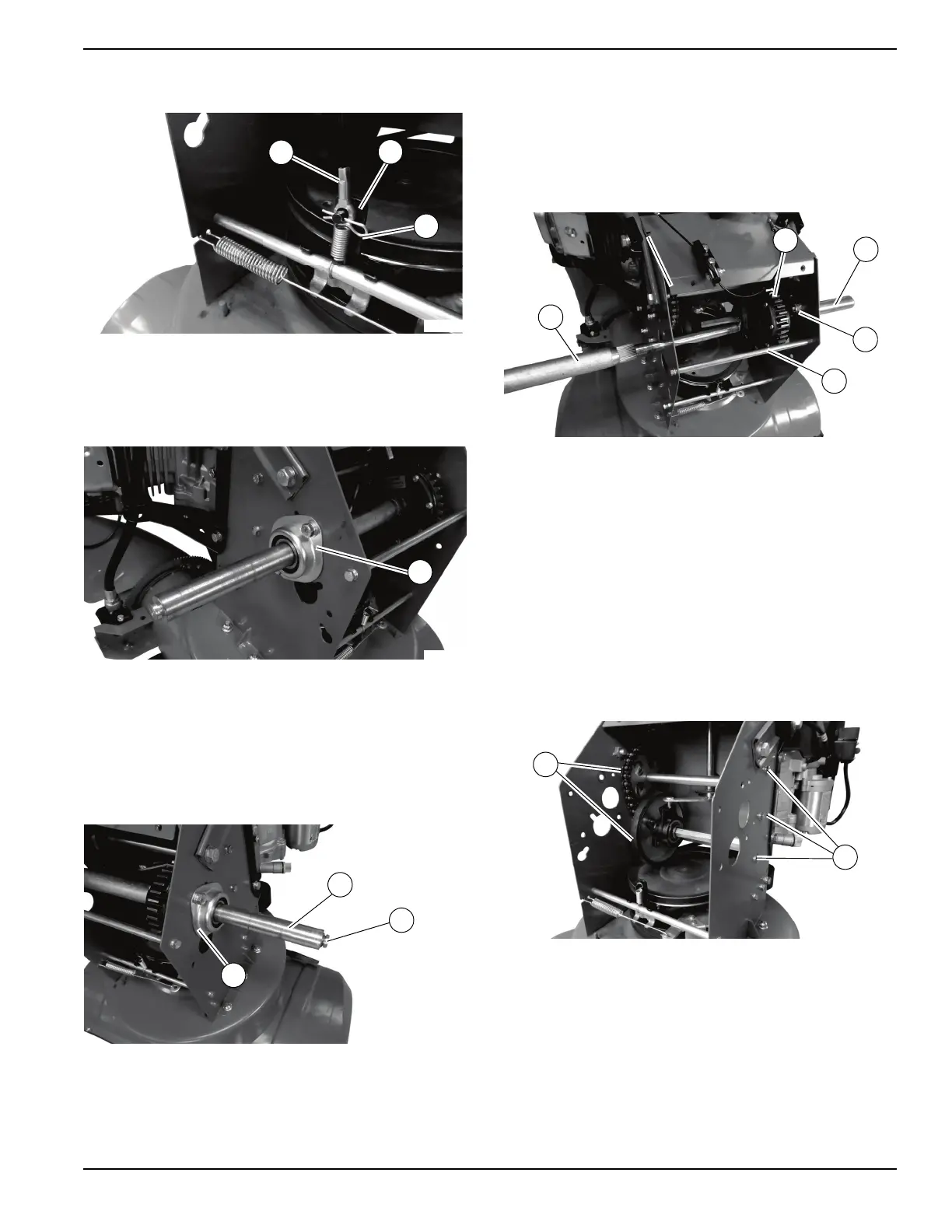

13. See Figure 4-26. Remove the two rear strut bolts

and lock washers using a 10mm wrench and

re

move strut (P).

Figure 4-26. Rear Strut Assembly

NOTE: V

erify the orientation of the differential (Q) on the

shaft before removing it (bolt heads facing left side of

machine), to keep it in the same orientation during

assembly.

14. Remo

ve the long shaft (T), short semi-shaft, shaft

sleeve (Q), and differential (S).

NOTE: A

dead blow hammer may be used to tap the dif-

ferential to separate it from the shaft splines for removal.

15. See Figure 4-27. Remove the six bolts, lock wash-

ers and flat washers (U) securing the friction drive

whe

el assembly (V) using a 10mm wrench.

Figure 4-27. Removing Friction Drive Wheel

Assembly

16. Carefully remove fric

tion wheel assembly. Verify

everything stays together.

NOTE: V

erify the chain side of the friction drive wheel

assembly stays together during the following steps for an

easier installation.

Loading...

Loading...