6 Owner’s Manual for Power Zone Pro Main Controller

General Information

Features

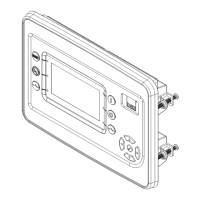

• HMI 4.3 inch Color Touchscreen Display

• System Configurable via the Connectivity server

using most Wi-Fi

®

, Bluetooth

®

devices, or wired

Ethernet connection

• Remote Communication via Modbus

®

RTU,

Modbus TCP/IP, 10/100 Mbs Ethernet IEEE 802.3

or Wi-Fi

• Configurable Analog and Digital I/O

• Configurable Monitoring of Analog I/O, Digital I/O,

and Machine State Data

• Configurable Detection and Mitigation of Faults

with E-Mail Annunciation

• Configurable Logging of Faults and Events with

Associated Data Capture

• Configurable Logging and Trending of Data

• Digitally Controlled Generator Output Voltage and

Frequency Regulation

• Customer Programmable Built-in Multichannel PLC

Logic Controller

• Alternator I

2

T with 300% Current Limiting for

Breaker Coordination

• Alternator Ground Fault Indication

Parameters Monitored on Display or

Connectivity Server

•

Keyswitch Position Monitoring

• Amps per Phase - Generator

• Line to Line and Line to Neutral Volts - Utility and

Generator

• Power Factor - Generator

• Real Power - kW - Generator

• Apparent Power - kVA - Generator

• Reactive Power - kVAR - Generator

• Frequency - Utility and Generator

• Engine Speed

• Engine Coolant Temperature

• Engine Oil Pressure

• Engine Oil Temperature

• Battery Voltage

• Shutdown Messages

• Diagnostics

• Maintenance Events/Information

• Engine Run Hours

Voltage Regulation (Single or Three-Phase

Module Options)

•

Digital Control

• Single-Phase or Three-Phase RMS Sensing with

Loss of Sensing Protection

• Variable V/F Slope Settings and Adjustable Gains

• Negative Power Protection

• Soft Start Ramping

• Fault Protection (I

2

T Function and GFI)

Electronic Governor

•

Electronic Speed Control for Electronically

Controlled Compression and Spark Ignited

Engines

• Adjustable Gains

• Low Speed Exercise

PLC (Built-In Programmable Logic Controller)

•

Configurable Through Software Tool

• Customer Configurable for Non-Standard Options

• Up to 8 Simultaneously Running PLC Programs or

in Sequence

Connections

•

21 Digital Outputs Maximum (Open Drain, 35 V

1.7 A)

• 7 fast PWM capable Outputs, 1 High Current

• 15 Digital Inputs Maximum

• 7 fast PWM capable Inputs

• 12 General Purpose Analog Inputs

• 2 Special Purpose Analog Inputs

• 2 Analog Outputs (0-10 V )

• 1 E-Stop Relay Output

• 3 Current Sense Inputs

• 8 High Voltage Sense Inputs (3-Phase + Neutral)

• 1 Magnetic Pickup Input

• 1 Coolant Level Sensor Input

• 2 CAN bus Channels

• 2 External RS-485 Ports (1 available to customer)

• 2 Switchable 12 V Power Outputs

NOTE: Actual I/O may vary due to configuration.

Qualification Testing

•

Life Test in Environmental Chamber

• Temperature Rating

• Vibration Tested and Protected

Loading...

Loading...