Section 3 • Scheduled Maintenance Procedures January 2012

3 - 32 GS-30 • GS-32 • GS-46 • GS-47 Part No. 228901

Checklist D Procedures

D-1

Check the Scissor Arm

Wear Pads

Genie requires that this procedure be performed

every 1000 hours or annually, whichever comes

first.

Maintaining the condition of the scissor arm

wearpads is essential to safe machine operation.

Continued use of worn out wear pads may result in

component damage and unsafe operating

conditions.

Note: Perform this procedure with the platform in

the stowed position.

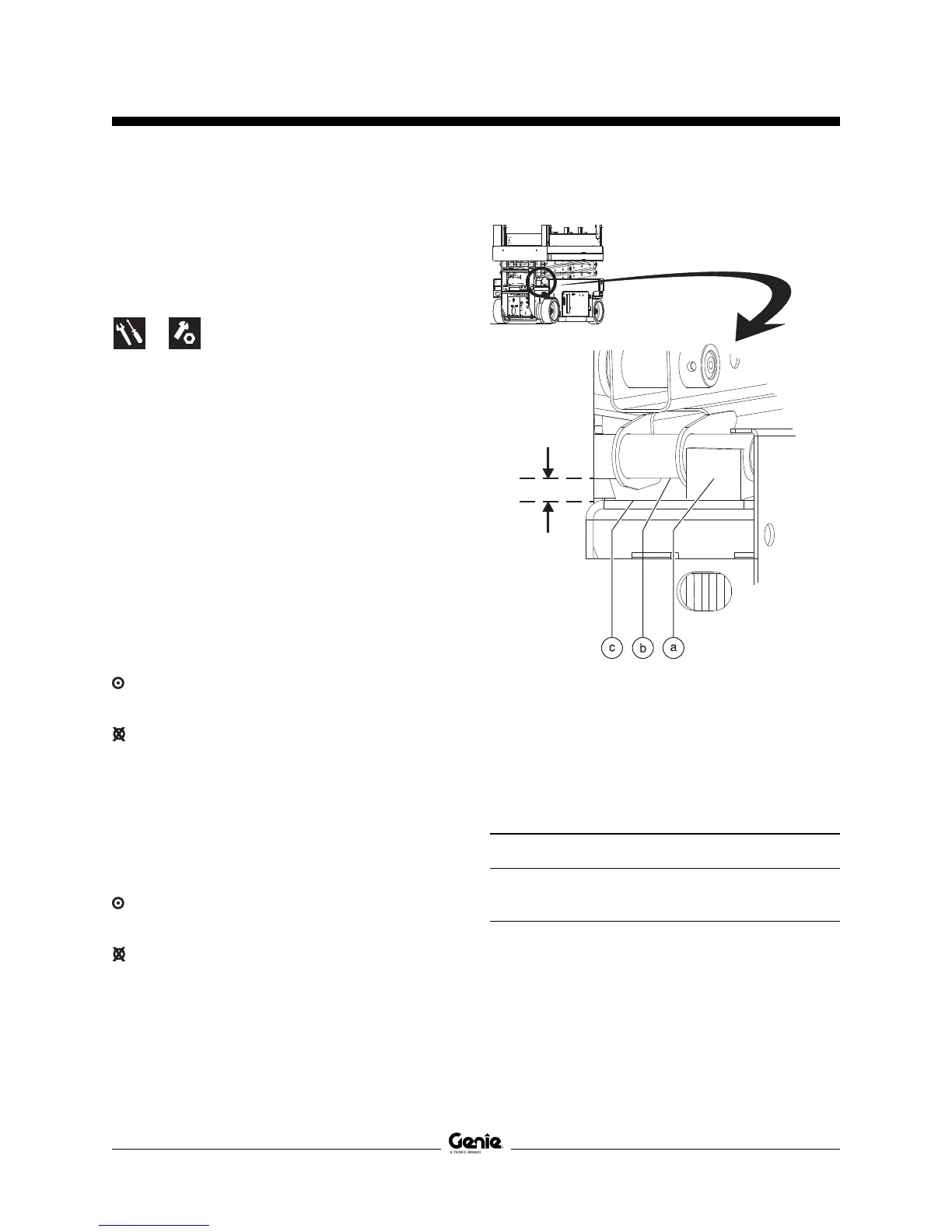

1 Measure the distance between the number one

inner arm cross tube and the chassis deck at

the ground controls side of the non-steer end of

the machine. Refer to illustration 1.

Result: The measurement is

0.90 inch / 22.9 mm or more. Proceed to step 2.

Result: The measurement is less than

0.90 inch / 22.9 mm. Replace both wear pads.

Refer to Repair Procedure 9-1 or 9-2,

How to

Replace the Scissor Arm Wear Pads

.

2 Measure the distance between the number one

inner arm cross tube and the chassis deck at

the battery pack side of the non-steer end of

the machine. Refer to illustration 1.

Result: The measurement is

0.90 inch / 22.9 mm or more. Proceed to step 3.

Result: The measurement is less than

0.90 inch / 22.9 mm. Replace both wear pads.

Refer to Repair Procedure 9-1 or 9-2,

How to

Replace the Scissor Arm Wear Pads.

Illustration 1

a wear pad

b inner arm cross tube

c chassis deck

3 Apply a thin layer of dry film lubricant to the

area of the chassis where the scissor arm wear

pads make contact.

Cross tube to chassis specification

Measurement, minimum 0.90 inch

22.9 mm

Loading...

Loading...