Using the shifter, shift into third gear. In third gear,

the gear cable A on the right dropout should not be

able to be pulled out from the wheel hub any further.

If this is not the case, this means the shift cable is too

slack.

If you cannot shift into third gear, turn the

nuts on the gear shifter inwards (clockwise)

as the shift cable is too taught. You can also

on the right dropout

out of the plastic sleeve of the shift cable a

little ways.

If you can still pull the shift cable “A”

out

further, turn the nuts on the gear shifter

clockwise). You can also

move the plastic sleeve of the shift cable a

little further on gear cable “A”

After the adjustment, run through the gears several

times for testing purposes.

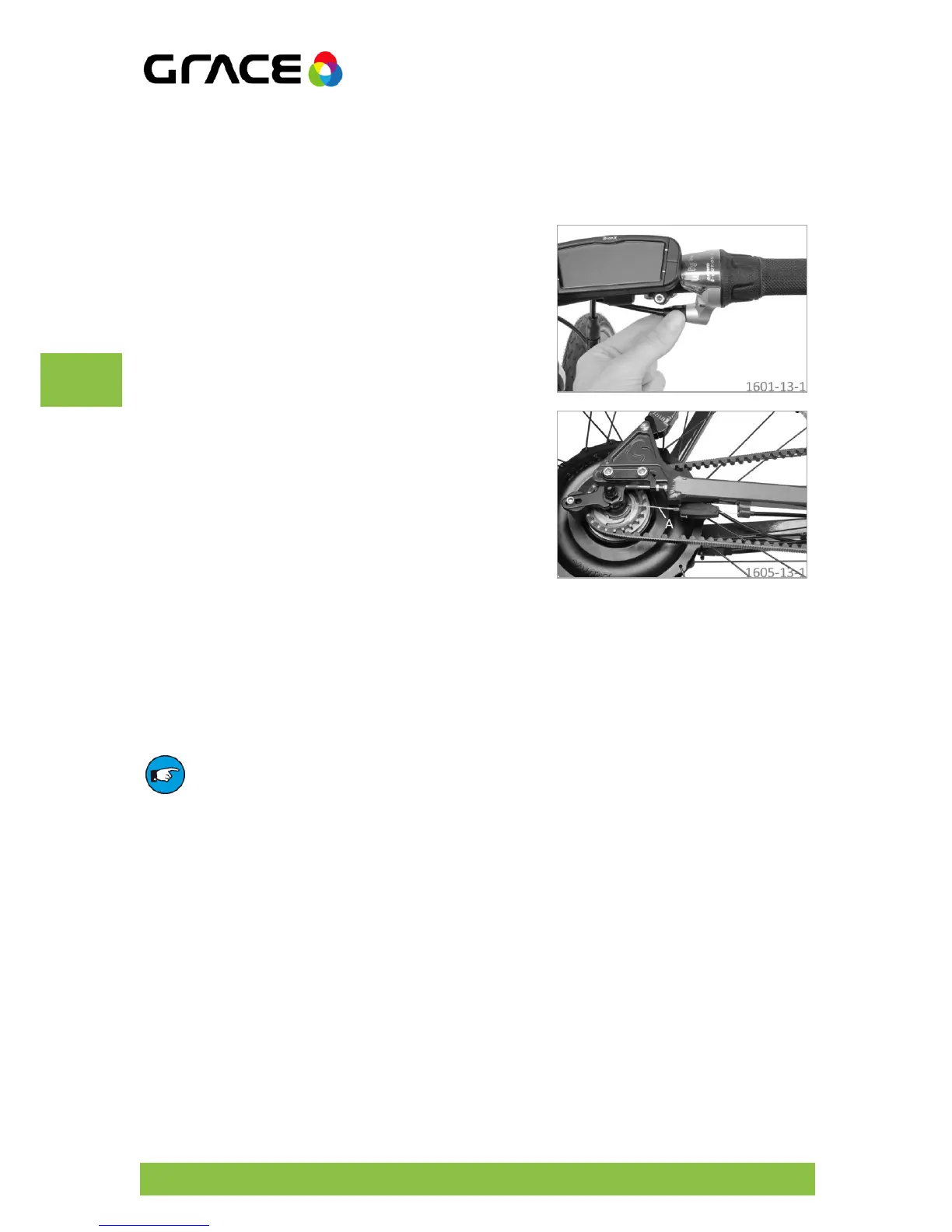

5.5. Tensioning and aligning the drive belt

If the tension on the drive belt is not set correctly, this can cause damage to the

drive belt and other components.

If the tension of the drive belt is too low, the drive belt may slip on the timing

pulley. This may cause damage to the carbon fibres inside the drive belt. If the drive

belt has slipped, you must have it replaced by a specialist workshop.

on the drive belt is too high, this may cause damage to the bearings

and seals in the wheel hub. This also increases the wear and frictional losses in the

entire drive.

Loading...

Loading...