Troubleshooting

26 3A8099A

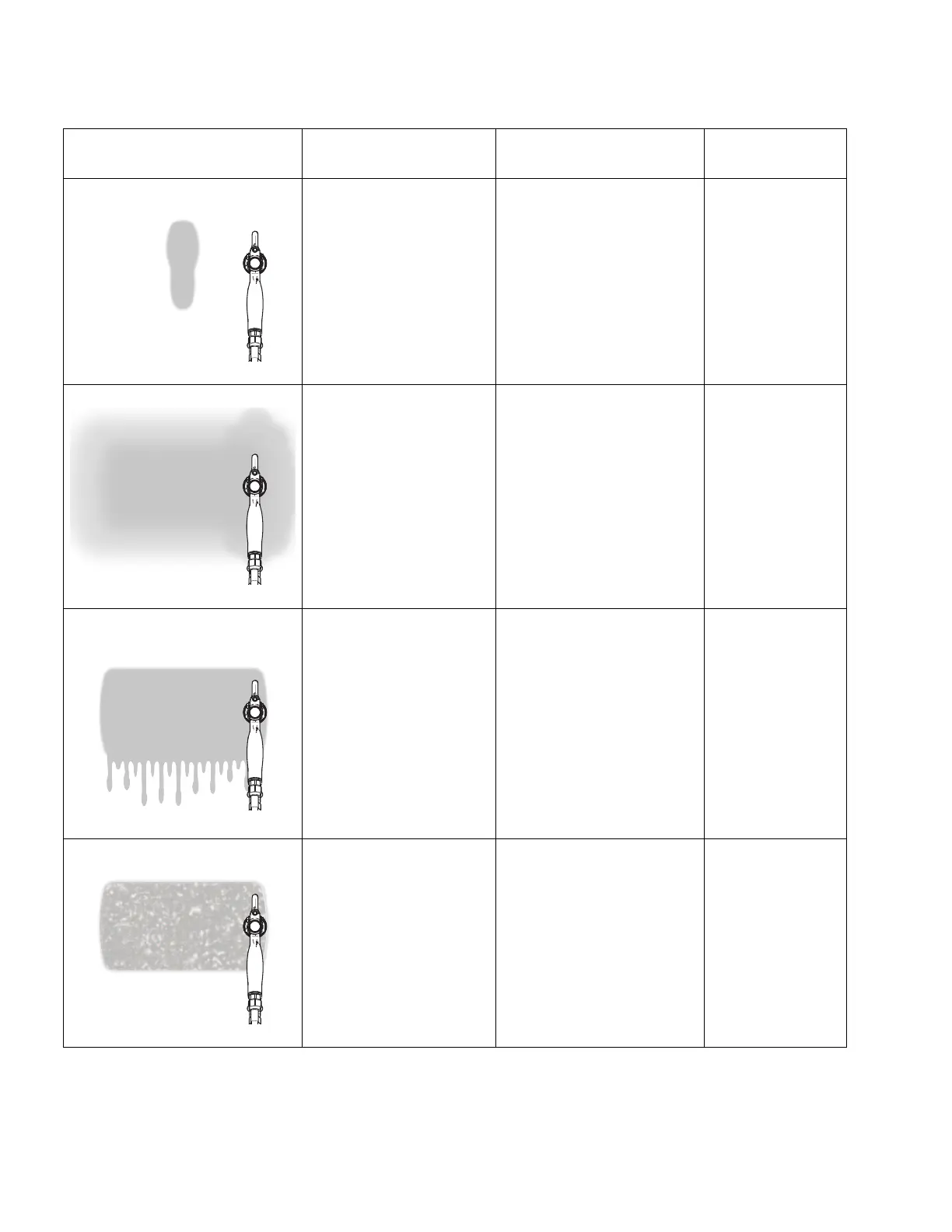

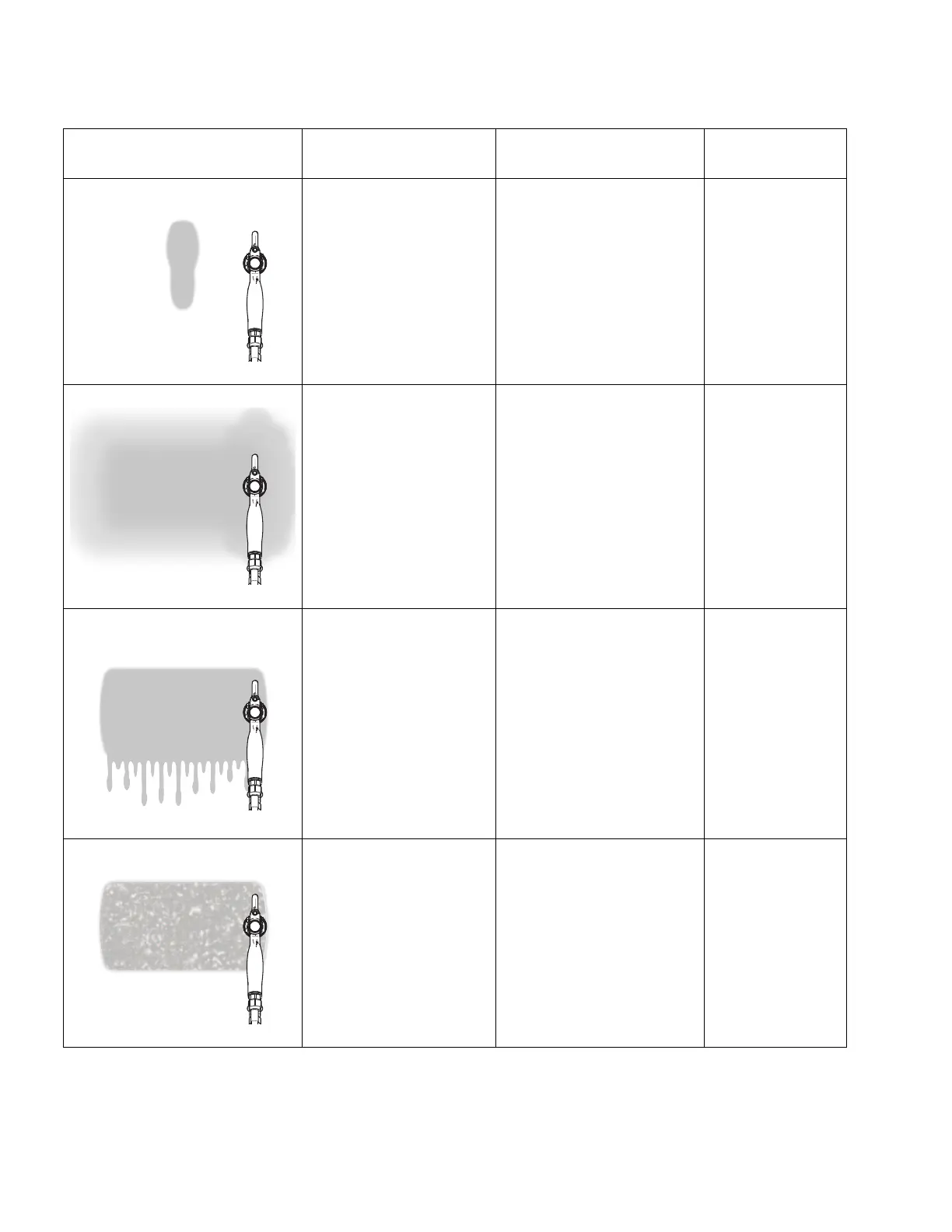

Irregular pattern

• Spray tip partially

plugged

• Dirty or plugged air

cap holes

• Clean or replace tip

• Clean or replace air cap

• Test different types of air

caps

• Even and

blended finish

• Even 50%

overlaps

• Even paint

thickness and

coverage

Fogging, overspray, or dry spray

• Too much atomization

air

• Too high of fluid

pressure

• Incorrect tip size

• Reduce air pressure

• Decrease fluid pressure

• Increase tip orifice size

• Increase

transfer

efficiency

• Decrease

overspray

• Improves

spray booth

cleanliness

Paint runs or Paint Coverage

Thickness

• Too much fluid flow

• Tip worn

• Incorrect tip size

• Operator spray

technique

• Check tip wear and flow

rate

• Decrease tip orifice size

• Review operator

technique

• Minimizes runs

• Maintains

transfer

efficiency

• Even paint

thickness and

coverage

• Even 50%

overlaps

Rough finish or specking

• Too much atomization

air

• Too much fan pattern

adjustment

• Too much distance

between gun and part

• Decrease air pressure

• Decrease tip pattern size

• Adjust gun to part

distance

• Increases

wetness of the

paint on the

part

• Allows material

to flow evenly

• Even / blended

finish

Problem Possible Causes Solutions

Why it is

important

Loading...

Loading...