Setup

General Equipment Guidelines

Maintain and inspect the generator, air compressor,

and other equipment per the manufacturer

recommendations to avoid an unexpected shutdown.

Unexpected equipment shutdown will cause voltage

fluctuations that can damage electrical equipment.

Electrical Connections

Connect air compressor, breathing air, and auxiliary

power electrical connections to the specified circuit

breakers. See Circuit Breakers, page 32.

1. Remove one or more knock-outs on side

of electrical enclosure, as required, and

route wires through for air compressor,

breathing air, and auxiliary equipment. See

Circuit Breaker Configuration Options, page 33,

for more information.

Connect Feed Pumps

For illustrations of a system with feed pumps, see

Typical Installation, with circulation, page 15 and

Typical Installation, without circulation, page 14.

1. Install feed pumps (K) in component A and B

supply drums.

2. Seal component A drum and use desiccant dryer

(M) in vent.

3. Install agitator (L) in component B drum, if

necessary.

4. Connect supply hoses from feed pumps to the

component A and component B material inlets

on the system. Ensure A and B inlet valves are

closed.

Note

Supply hoses from feed pumps should

be 3/4 in. (199 mm) ID.

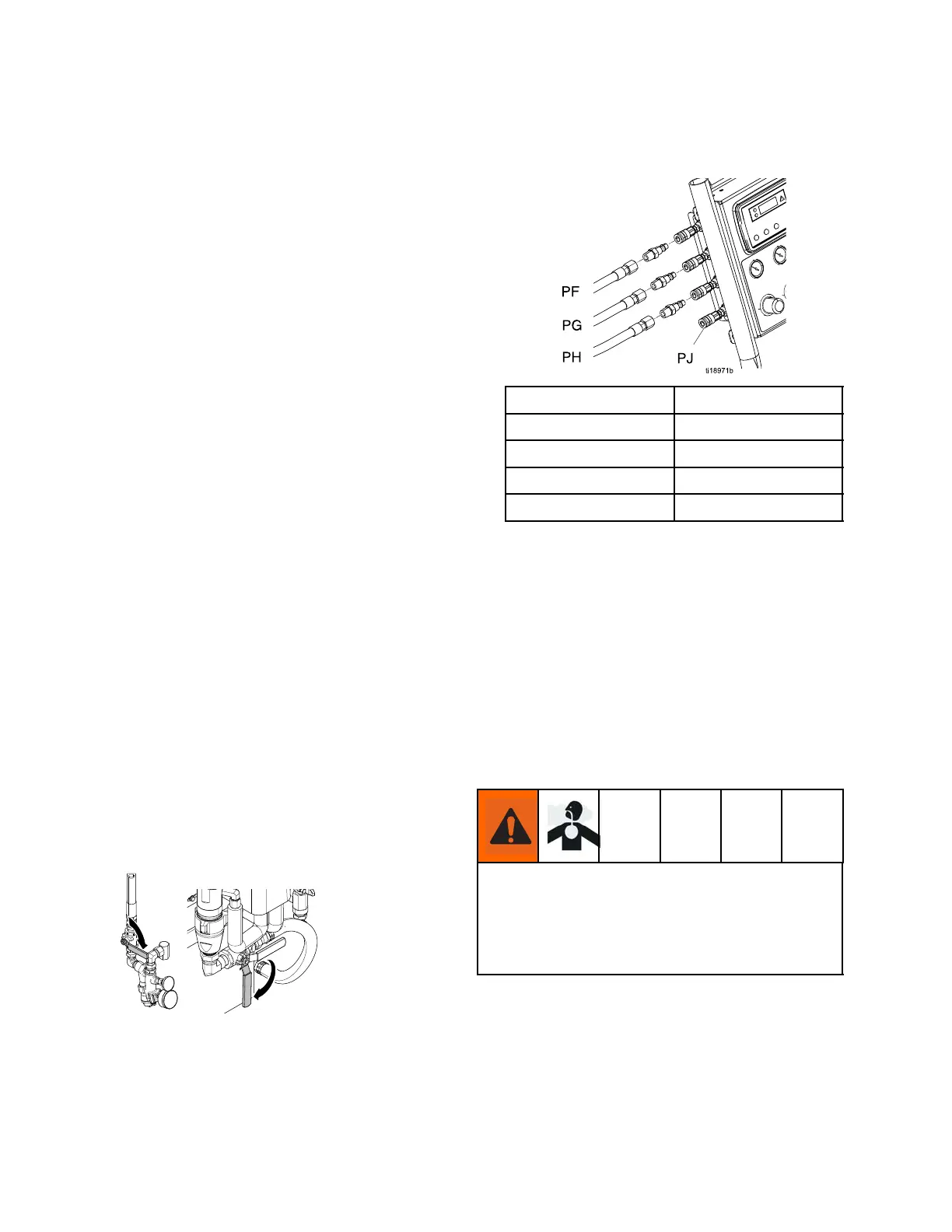

5. Connect air lines to proportioner. Ensure

components are properly connected to correct

location.

Ref Air Outlet

PF A Pump

PG

BPump

PH Agitator

PJ Gun

Note

Agitator air supply (PH) includes a small

internalrestrictionorificetolimittheair

flow to minimize air compressor load.

Maximum supplied air flow is 2.0 scfm

(0.1 m3/min) at 100 psi (0.7 MPa, 7 bar).

Designed for use with Twistork agitator

224854. Do not use the agitator air outlet

(PH) for any other component.

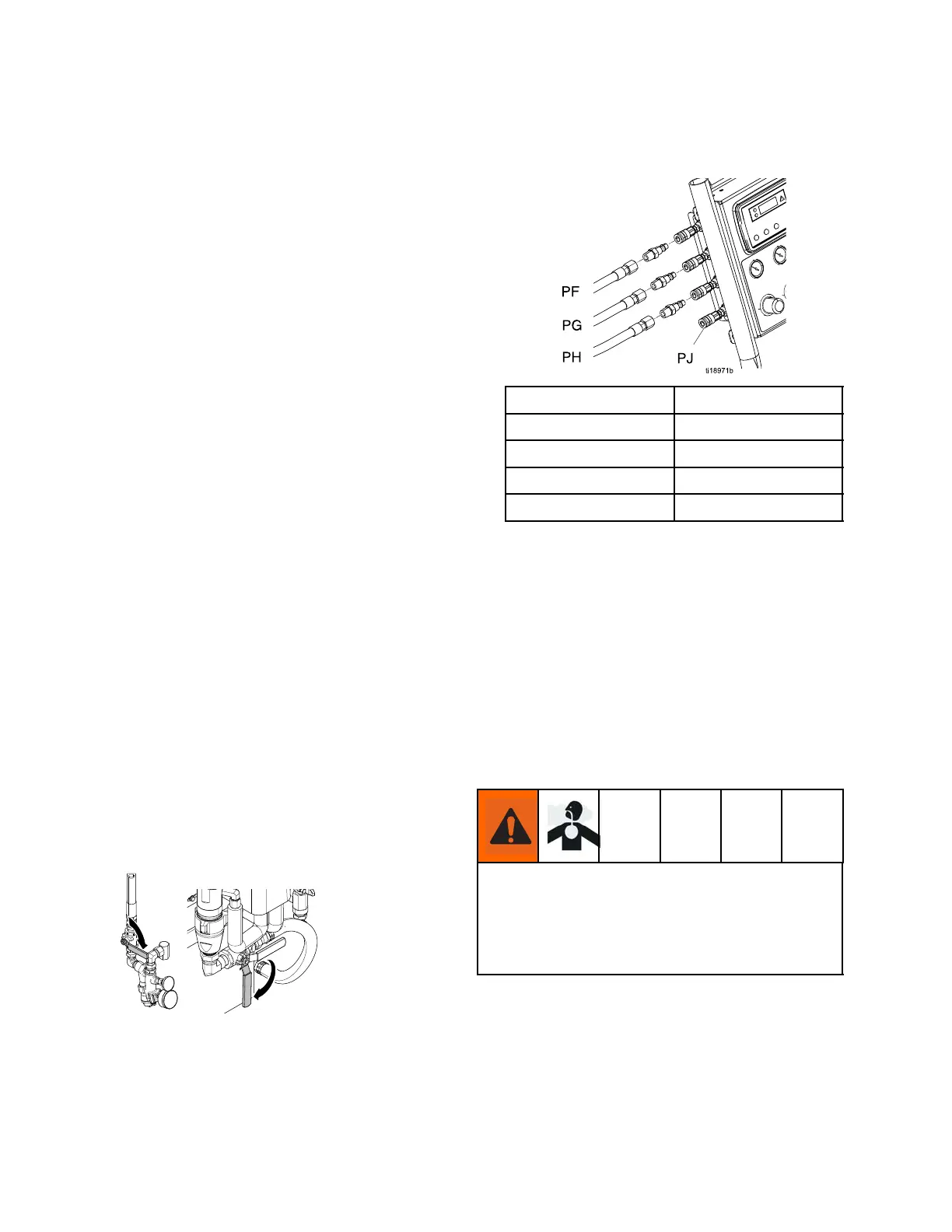

Breathing Air

Breathing the air from the compressed air supply

can cause serious injury if inhaled.

• Only use an independent and approved

breathing air system with adequate air flow to

provide clean breathable air.

42

332636C

Loading...

Loading...