Setup

18 312062A

4. Connect feed pumps

a. Install feed pumps (K) in component A and B

supply drums. See F

IG. 1 and FIG. 2, pages 8

and 9.

b. Seal component A drum and use desiccant

dryer (M) in vent.

c. Install agitator (L) in component B drum, if nec-

essary.

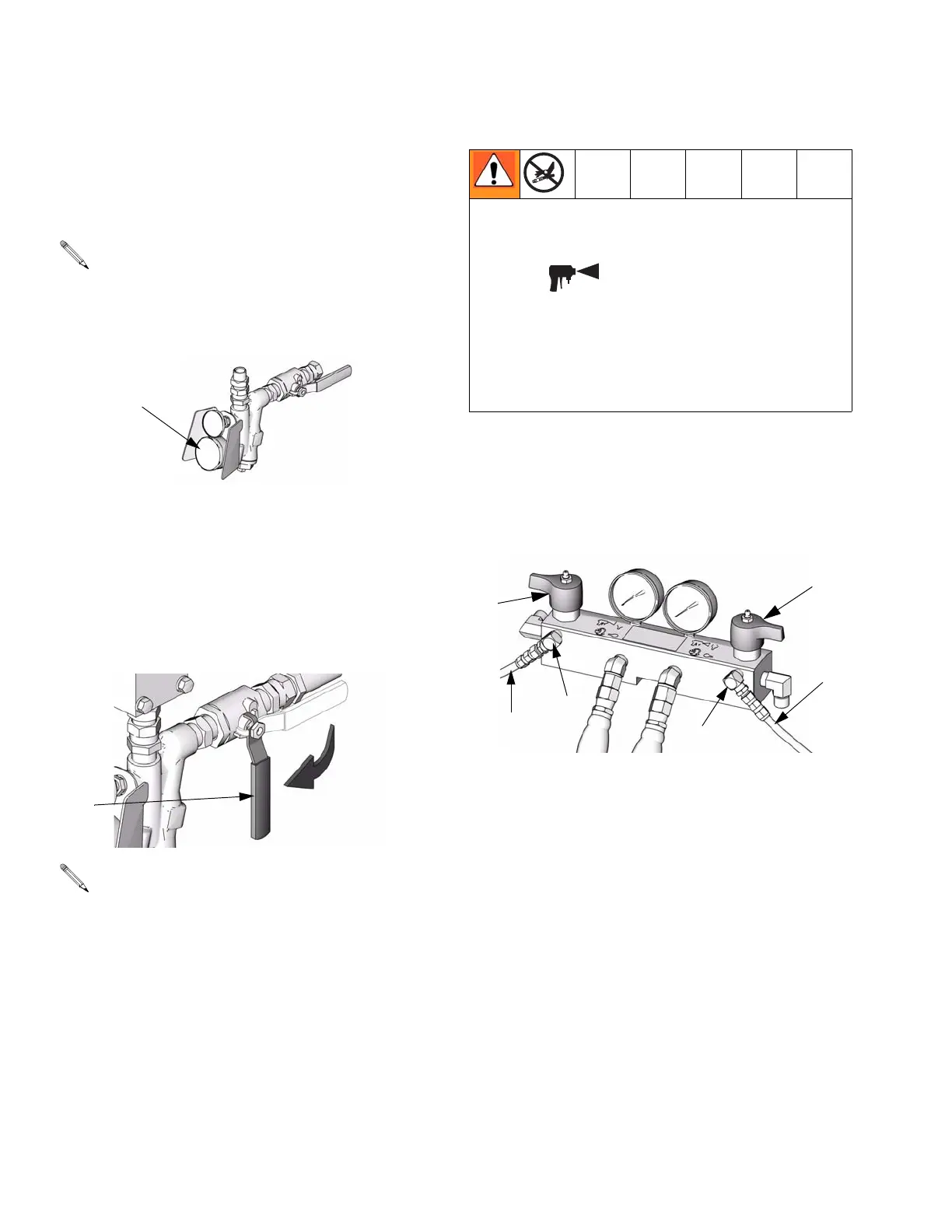

d. Ensure A and B inlet valves (FV) are closed.

e. Connect and tighten component B supply hose

to the 3/4 npt(f) swivel on the component B inlet

valve.

f. Connect and tighten component A supply hose

to the 1/2 npt(f) swivel on the component A inlet

valve.

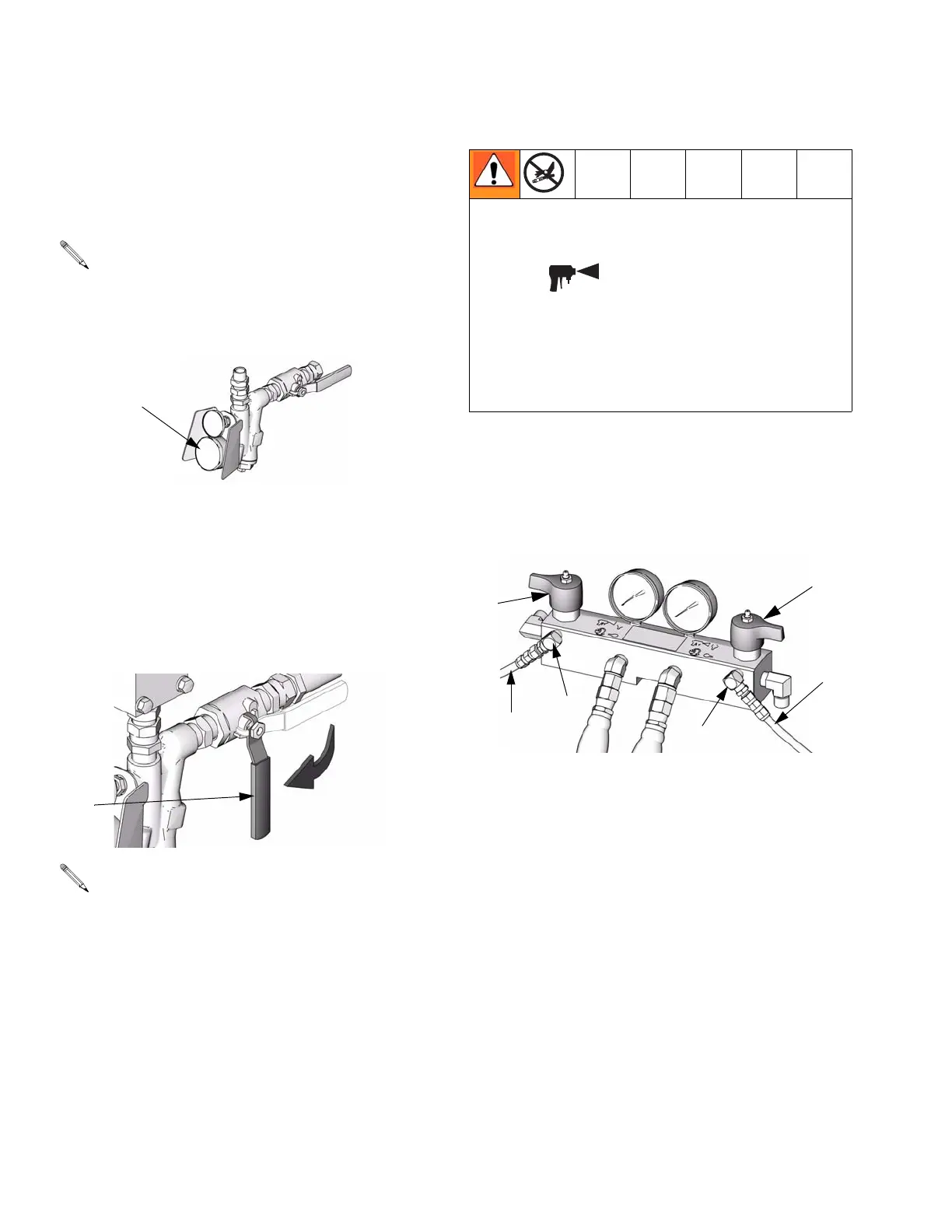

5. Connect pressure relief lines

a. Recommended: Connect high pressure hose

(R) to relief fittings (BA, BB) of both PRES-

SURE RELIEF/SPRAY valves, Route hose back

to component A and B drums. See F

IG. 1, page

8.

b. Alternately: Secure supplied bleed tubes (N) in

grounded, sealed waste containers (H). See

F

IG. 2, page 9.

6. Install Fluid Temperature Sensor (FTS)

The Fluid Temperature Sensor (FTS) is supplied. Install

FTS between main hose and whip hose. See Heated

Hose manual 309572 for instructions.

A minimum feed pressure of 50 psi (0.35 MPa, 3.5

bar) is required at both feed inlet pressure gauges

(FP). Maximum feed pressure is 250 psi (1.75 MPa,

17.5 bar). Maintain A and B feed pressures within

10% of each other.

Supply hoses from feed pumps should be 3/4 in.

(19 mm) ID.

FP

ti10006a

FV

ti9883a

Do not install shutoffs downstream of the PRES-

SURE RELIEF/SPRAY valve outlets (BA, BB). The

valves function as overpressure relief valves when set

to SPRAY . Lines must be open so valves can

automatically relieve pressure when machine is oper-

ating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum work-

ing pressure of this equipment.

ti9880a

BA

BB

R

R

SB

SA

Loading...

Loading...