4 - 13

2. Raise the seat plate.

3. Remove the check plug. Oil level should be at the

top of the check tube.

To add oil:

1. Remove breather. Add oil to fill tube until oil level

can be seen in check tube.

2. Replace breather and check plug.

IMPORTANT: To prevent severe damage to

transmission, always maintain proper oil level.

Check oil daily after changing transmission oil and/or

filter. Add oil if necessary. Continue daily checks until

oil level is stable.

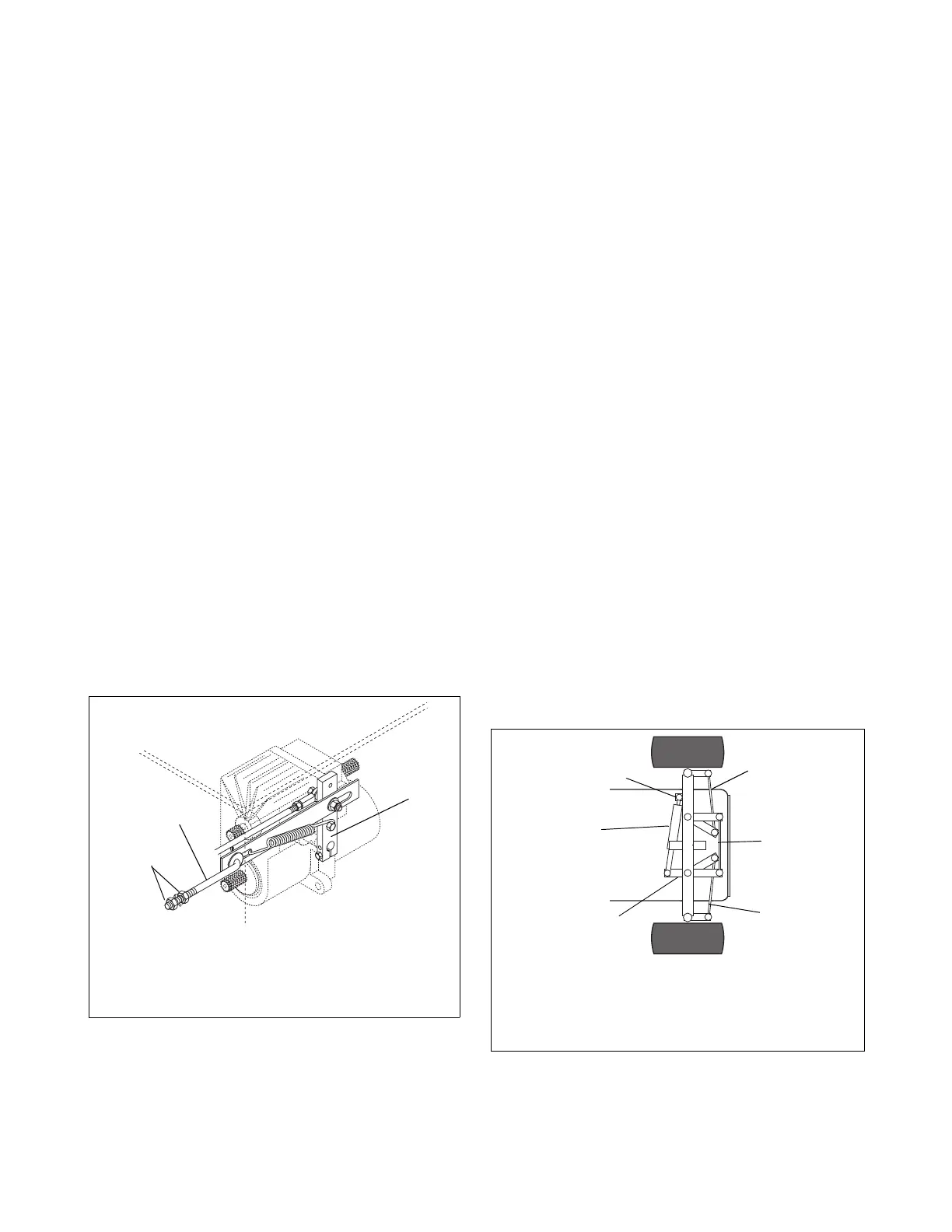

4.4 TRANSMISSION NEUTRAL

The direction control pedal should return to neutral

after foot pressure is removed. If the unit creeps while

in neutral, the neutral stop mechanism may need

adjusting (Figure 4).

NOTE: Adjusting the neutral at operating temperature

is recommended.

1. Stop the engine, remove the ignition key, and lock

the brakes.

2. Raise the seat plate and loosen the hex nuts on

the neutral detent rod.

3. Loosen/tighten hex nuts to shift pump arm in

opposite direction of the creep. Make small

adjustment (one turn or less.)

4. Tighten the hex nuts.

5. Run the unit and check for creeping.

6. Repeat above steps as necessary.

4.5 TIRES AND WHEELS

Tires

Before each use, make a visual check of the tires.

Check the pressure every 25 hours. See the side wall

for correct air pressure.

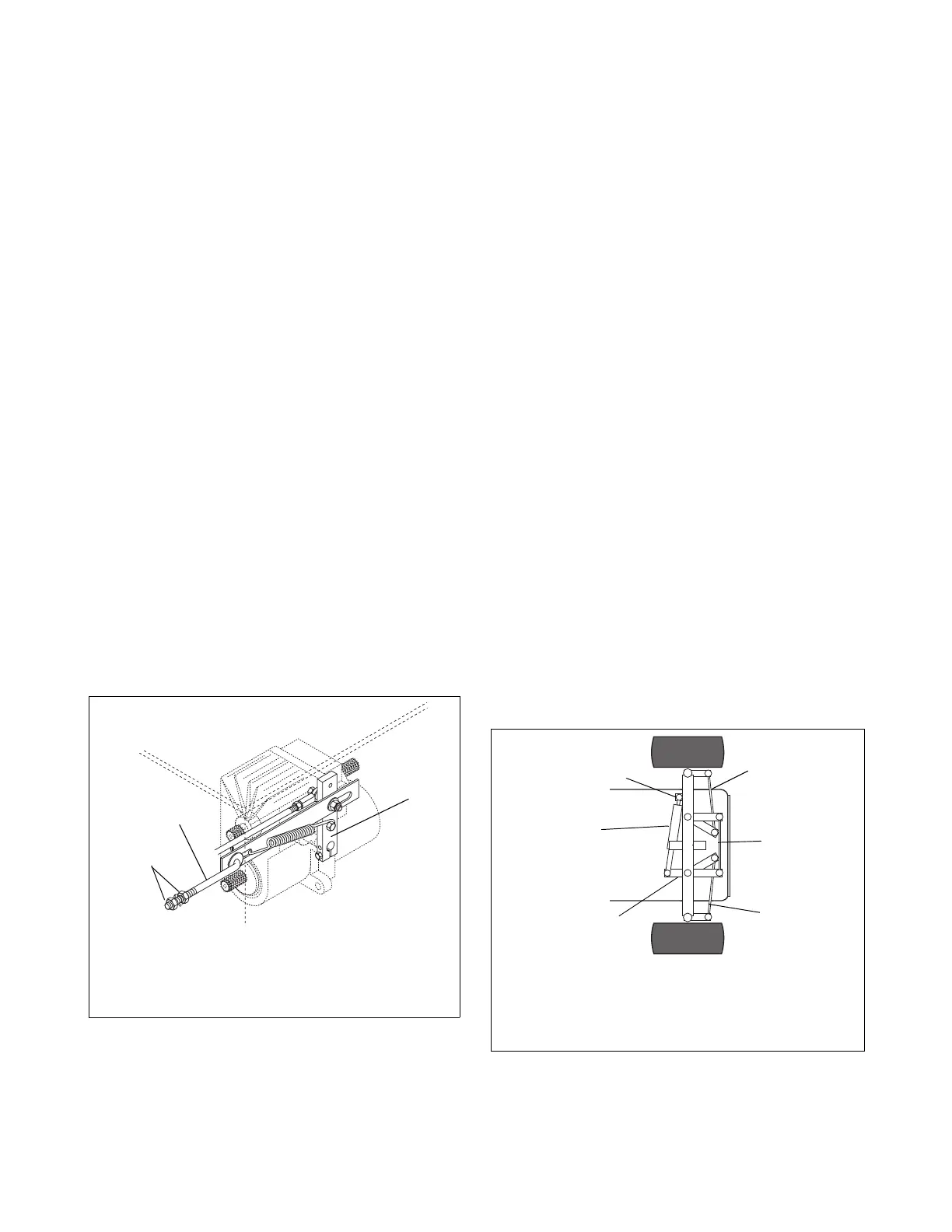

Wheel Alignment

Proper alignment of rear wheels is necessary to assure

proper steering and to reduce tire wear. Proper toe-in is

when the front of the wheels are 1/16" to 1/8" closer

together than the rear of wheels, measured at

horizontal center line of rim flange.

If unit steering wanders or excessive tire wear

develops, toe-in should be checked.

Outer tie rods should be adjusted equally; the correct

length is 13.25" from bolt centers.

The correct length for the center tie rod is 12.75" from

bolt centers on two wheel models. On models with four

wheel assist, the correct distance is 12.12". The center

tie rod should not be used to make other adjustments.

To change toe-in (Figure 5):

1. Loosen jam nuts on the outer tie rods.

2. Turn outer tie rods to adjust toe-in.

3. Tighten jam nuts.

4. Turn the wheels to each side until the idler arms

stop against the tab on the center of the axle. If the

idler arms do not reach the tab, the steering

cylinder is adjusted properly.

To adjust the steering cylinder (Figure 5):

1. Turn wheels so that cylinder is extended.

2. On one end of steering cylinder, loosen jam nut on

rod end and remove hardware fastening rod end.

3. Fully extended cylinder and lock rear wheels to

one side.

4. Turn rod end until it aligns with hole in axle

weldment or steering arm.

5. Replace hardware and tighten jam nut.

Figure 4

1. Hex Nuts

2. Detent Rod

3. Pump Arm

OF0790

1

2

3

Figure 5

1. Outer Tie Rods

2. Center Tie Rods

3. Steering Cylinder

4. Axle Weldment

5. Steering Arm

OF0800

1

1

2

3

4

5

Loading...

Loading...