8 - 41

8.2 HYDRAULIC LIFT SYSTEM

TROUBLESHOOTING

8.3 HYDRAULIC HOSES

NOTE: When loosening or tightening any hydraulic

hoses, use the correct wrench. If hoses are to be dis-

connected or reconnected at a fitting use two

wrenches, one on the hose and one on the fitting, to

prevent damage by twisting off the fitting.

1. When disconnecting hoses, have an open top

container to drain hydraulic oil into.

2. Clean all fittings and hoses where maintenance is

to be performed, prior to removing hoses to avoid

hydraulic system contamination. Cap hoses,

fittings and hydraulic component ports.

3. Repair or replace any worn or damaged hydraulic

items.

NOTE: Refer to the hydraulic diagram, Figure 54, for

proper hydraulic hose routing.

4. Fittings which use an O-ring seal do not use a

hydraulic sealer for preventing leaks. Fittings

without an O-ring seal, should use a hydraulic

sealer. Use caution not get hydraulic sealer into

hydraulic system.

5. After any hydraulic hose maintenance, refer to

Hydraulic System Servicing and Hydraulic System

Bleeding.

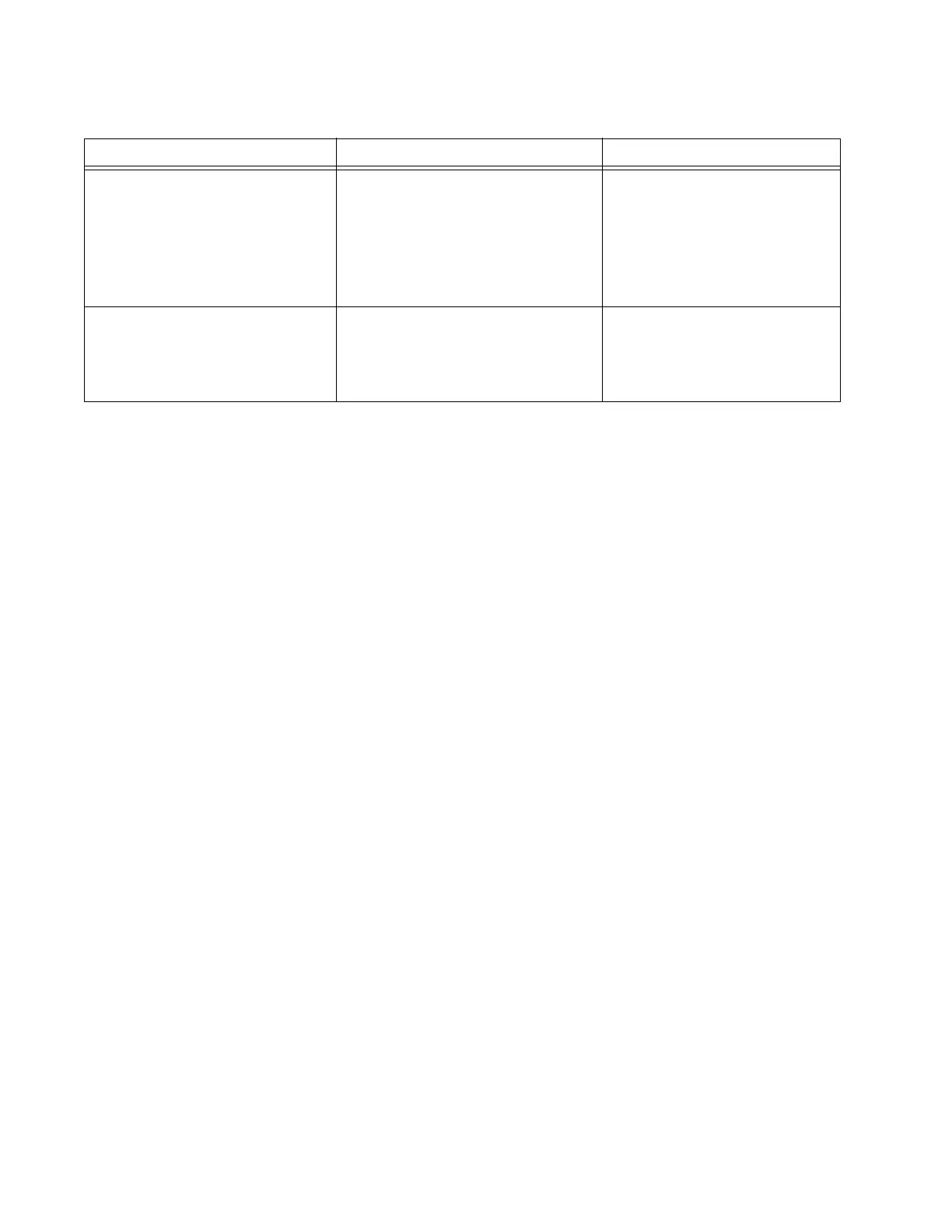

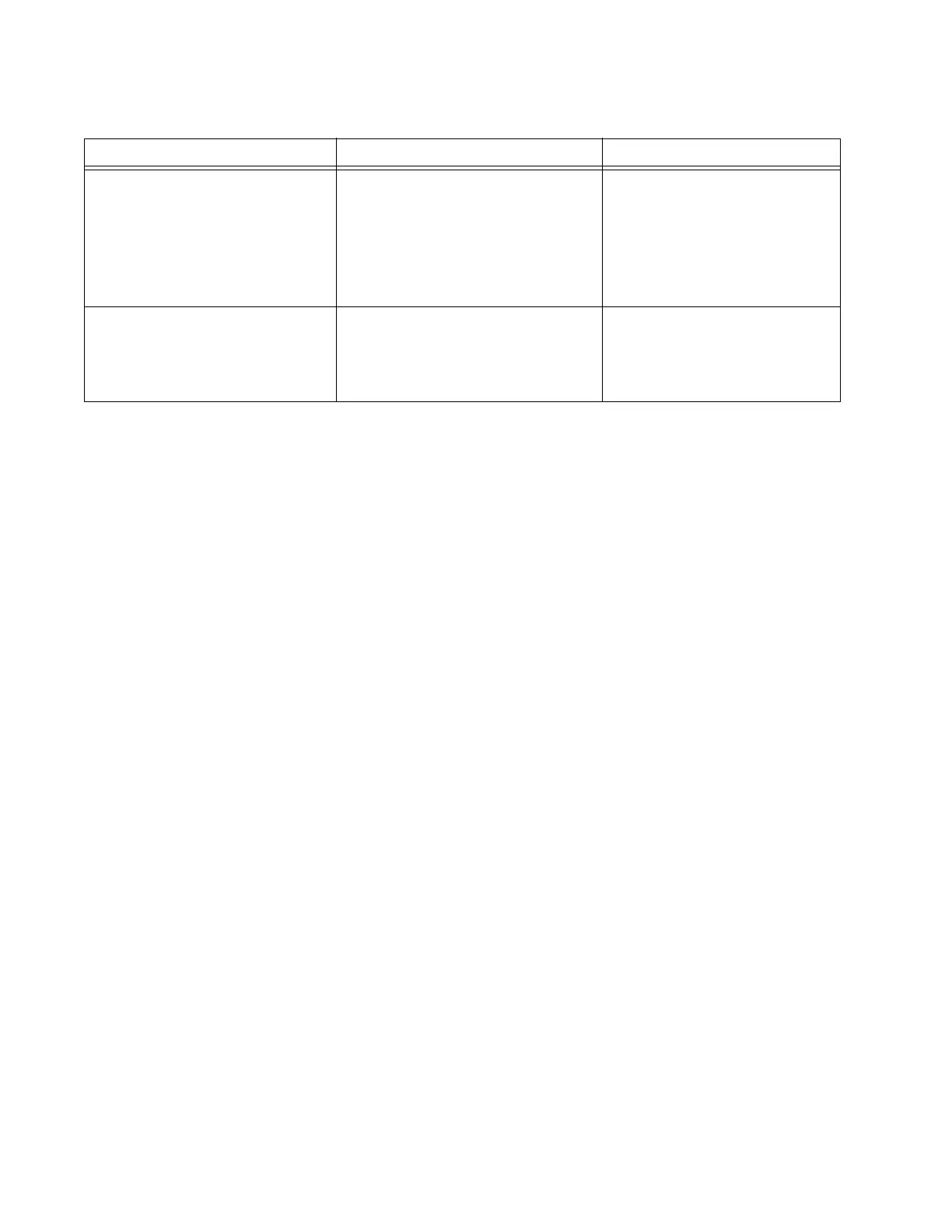

Problem Probable Cause Corrective Action

Mower deck will not raise Hydraulic system low on fluid

Pinched or restricted hydraulic hose

Air in system

Hydraulic valve or valve linkage

Transmission charge pressure too low

Add oil to hydraulic system

Repair or replace

Bleed hydraulic system

Repair or replace

Adjust

Mower deck bleeds down Transmission charge pressure too low

Hydraulic valve

Hydraulic hose or fitting leak

Lift Cylinder

Adjust

Replace

Repair or replace

Repair or replace

Loading...

Loading...