6 - 31

6.13 TRANSAXLE REMOVAL

NOTE: If attachment is installed it will have to be

removed.

1. Remove the transmission.

2. Remove the PTO gearbox.

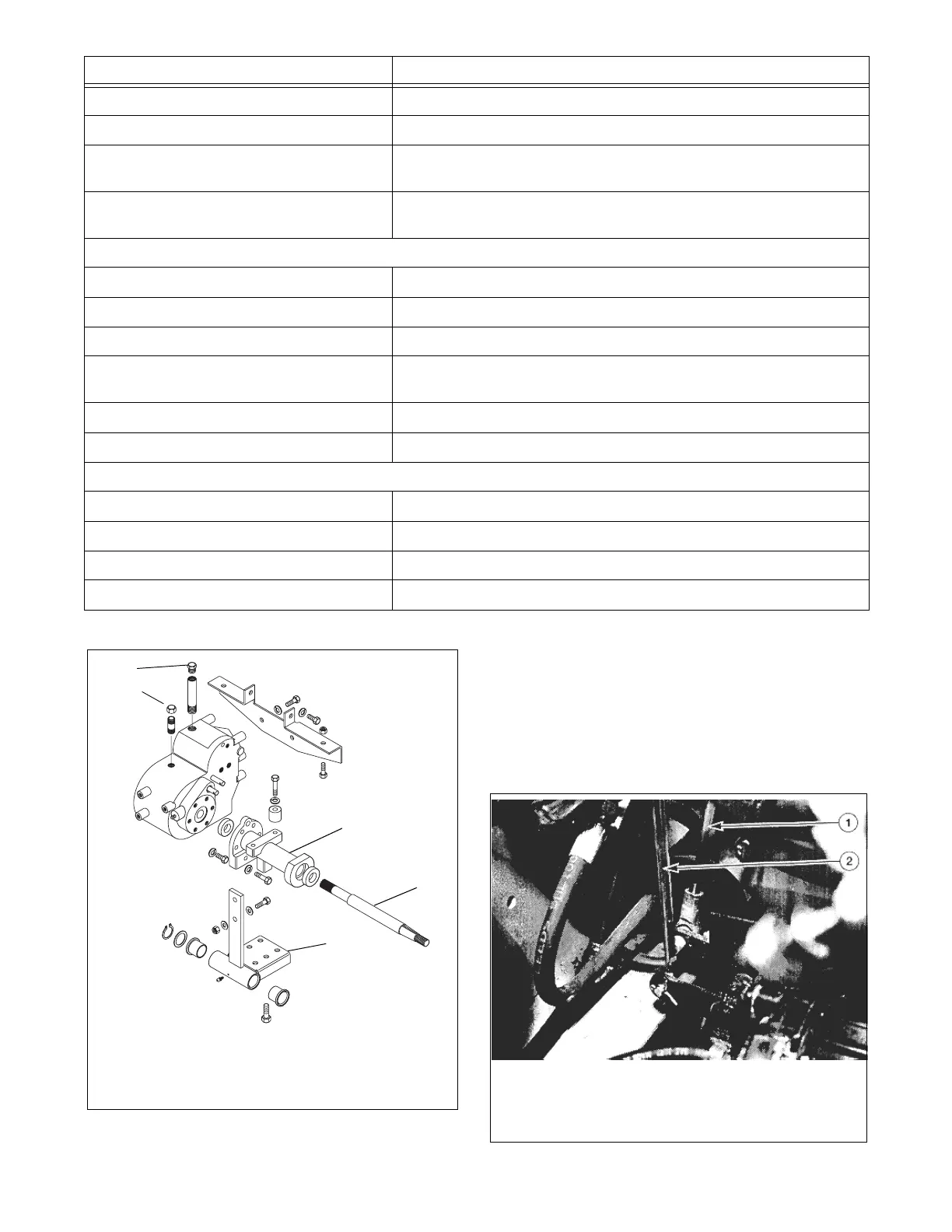

3. Disconnect the hi/low speed selector and

differential lock rods at the transaxle. See

Figure 36.

Shift lever bent and hitting unit frame Replace shift lever.

Shift rod grooves wornReplace shift rods.

Shift rod of improper length or grooving

installed

Check rod length. Replace with correct part.

Constant mesh gears improperly installed on

counter shaft

Reposition gears.

Axles cannot be turned (same direction) with unit in neutral gear

Axle housing not installed (or not tightened) Seal retainers are not properly sealed. Tighten axle housing bolts.

Burrs on gears Remove gear and hone smooth.

Parts missing Install missing parts.

Broken shifter stop allowing unit to be shifted

into two speeds at the same time.

Replace snap rings on shift rod out of groove.

Thrust washers in wrong position. Recheck thrust washer and reposition, if wrong.

Bearings not pressed in deep enough Use the proper bearing tool to seat the bearing.

Unit Does Not Drive

Differential bevel gears broken Replace.

Stripped teeth on gears Replace.

Keys sheared in drive pulleys Replace.

Broken input gear Replace.

CAUSE REMEDY

Figure 35

1. Breather Plug

2. Pipe Cap

3. Axle Housing

4. Axle with Taper

5. Pivot Bracket

Weldment

1

2

3

4

5

PF1202

Figure 36

1. Differential Lock

2. Hi/Low Speed Selector

Loading...

Loading...