6 - 27

5. Visually inspect the wear surfaces of the valve

plate, cylinder block and slippers for damage.

Check to be sure pistons move free in bores.

6. Remove the thrust plate from the counterbore in

the swashplate. Visually inspect both sides for

damage and flatness.

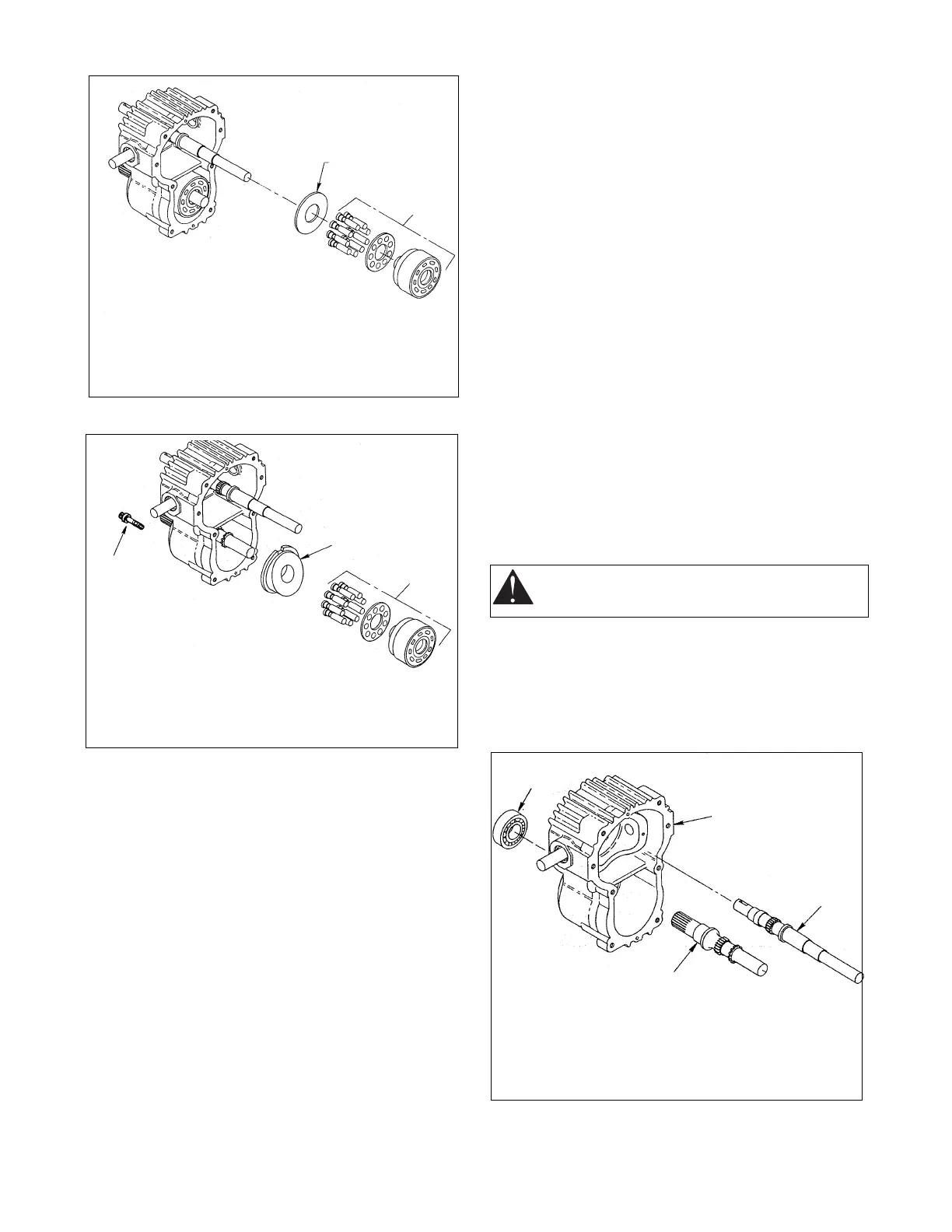

7. Lift out the motor (lower) cylinder block assembly,

Figure 28. This is the same for both pump and

motor. The pistons may come out of the cylinder

bores, however, there is no special orientation of

the piston to bore that needs to be maintained.

NOTE: Do not attempt to disassemble the spring and

other parts from the center bore of the cylinder block.

The entire assembly should be replaced if any of its

components are damaged.

8. Visually inspect the wear surfaces of the valve

plate, cylinder block and slippers for damage.

Check to be sure pistons move free in bores.

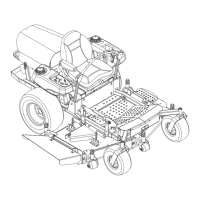

9. Remove the two cap screws then remove the fixed

swashplate from the counterbore in the housing.

Visually inspect the wear surface for damage.

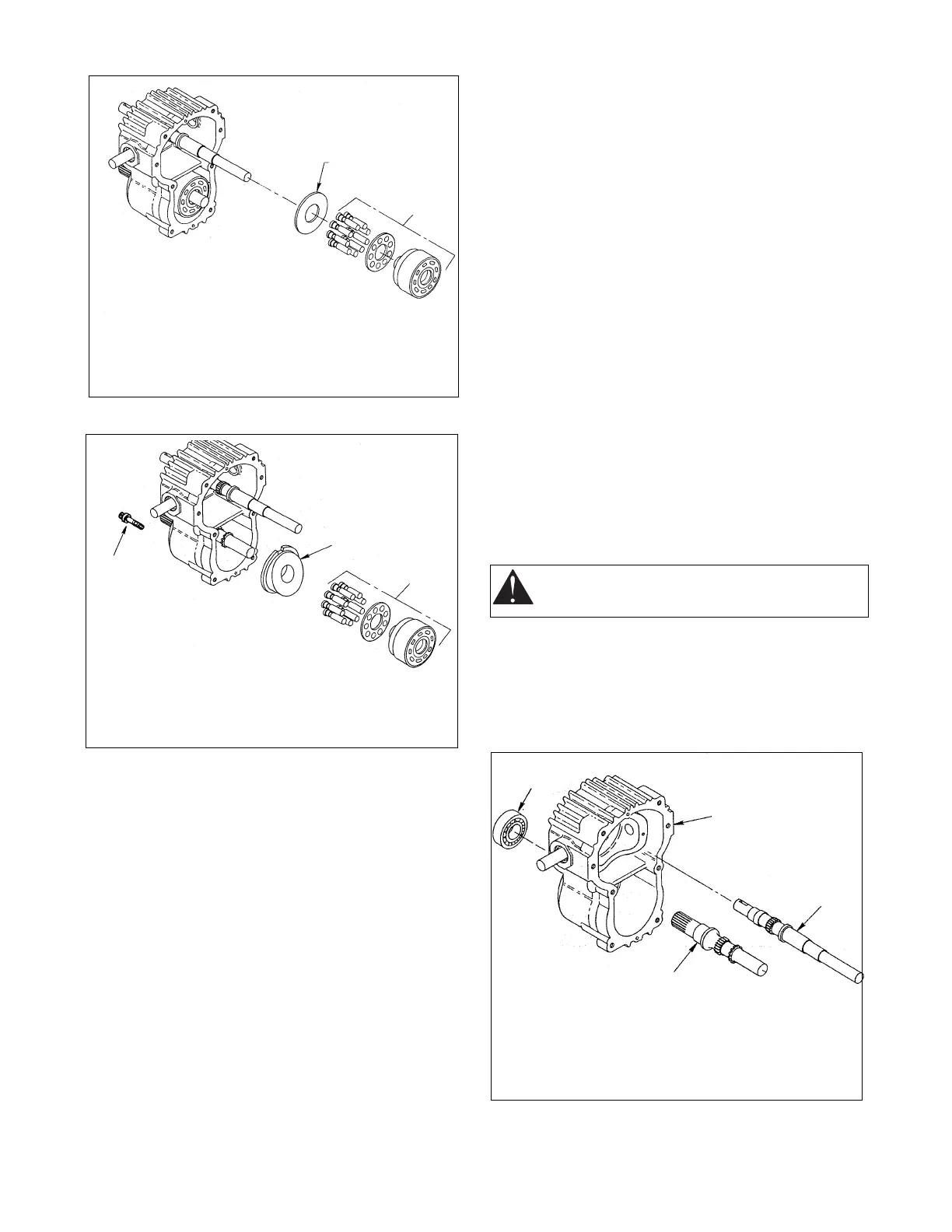

10.The pump shaft and motor shaft can be removed

by pressing them out through the large cavity of the

housing, Figure 29.

11.The motor shaft bearing is removed by pressing

out toward the front of the housing. Replace the

bearing if necessary.

12.Visually inspect the needle bearings and replace if

necessary by pressing them out of the center

section, Figure 30.

NOTE: When replacing the bearings, press into the

center section leaving 3/32" to 1/8" of bearing protrud-

ing beyond the face. The valve plates pilot on these

bearings.

13.Place the housing with the large cavity up. Use

care not to damage the housing. Place a 3/16"

diameter punch in the control shaft and tilt the

swashplate to its full angle (15 degrees, full

forward), Figure 31.

14.Use a second 3/16" diameter punch and drive out

the single pin in the trunnion shaft until it hits the

housing.

15.Drive both pins out of the control shaft until the first

pin contacts the housing. Twist the swashplate

(control shaft) back toward neutral and the first pin

and the pin on the trunnion shaft side should fall

into the housing.

Figure 27

1. Thrust Plate

2. Cylinder Block Assembly

1

2

Figure 28

1. Cap Screw

2. Swashplate

3. Cylinder

Block Assembly

1

2

3

CAUTION: Do not continue to drive the pin or

the housing will be damaged.

1

2

3

4

Figure 29

1. Bearing

2. Housing

3. Pump Shaft

4. Motor Shaft

Loading...

Loading...