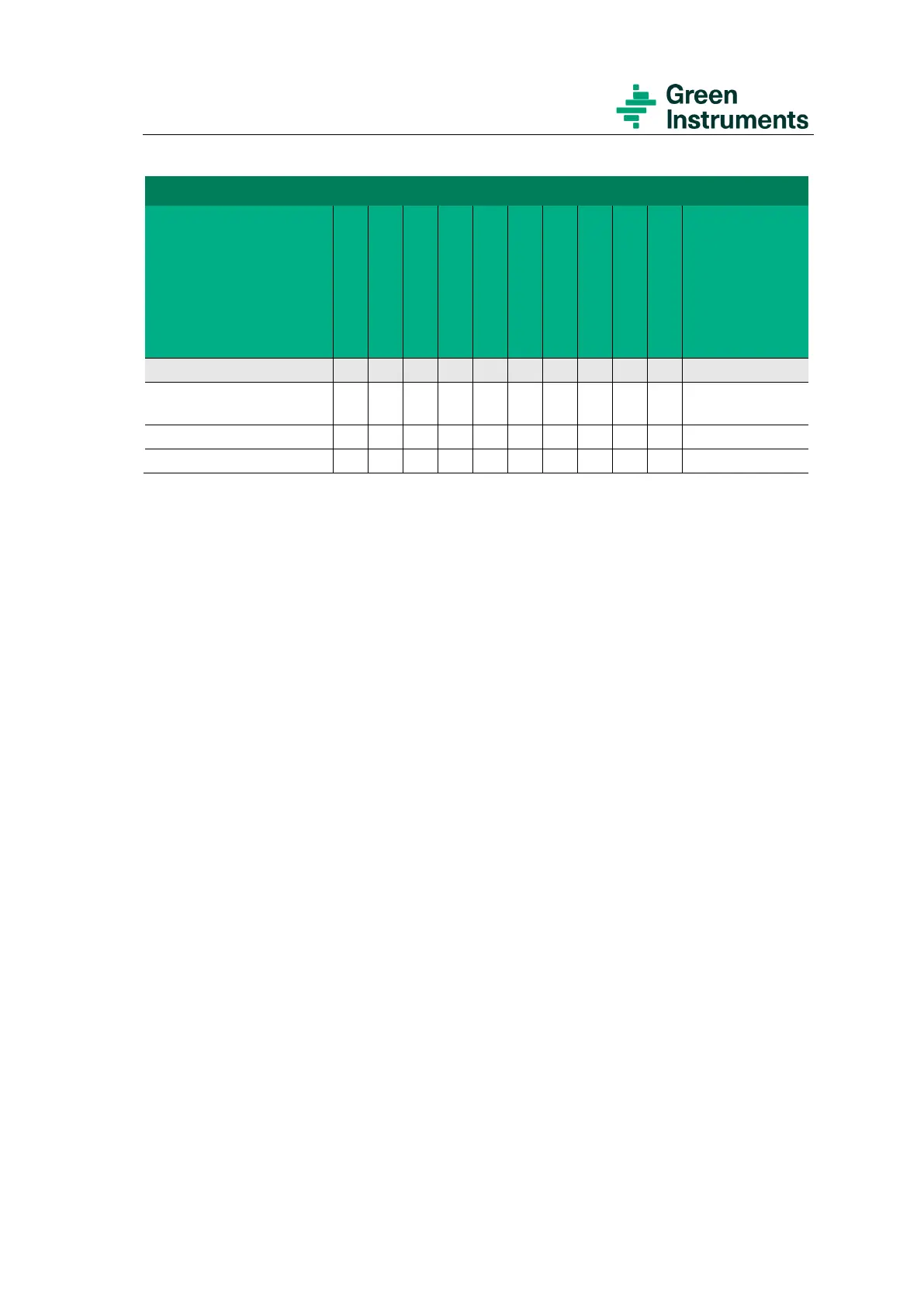

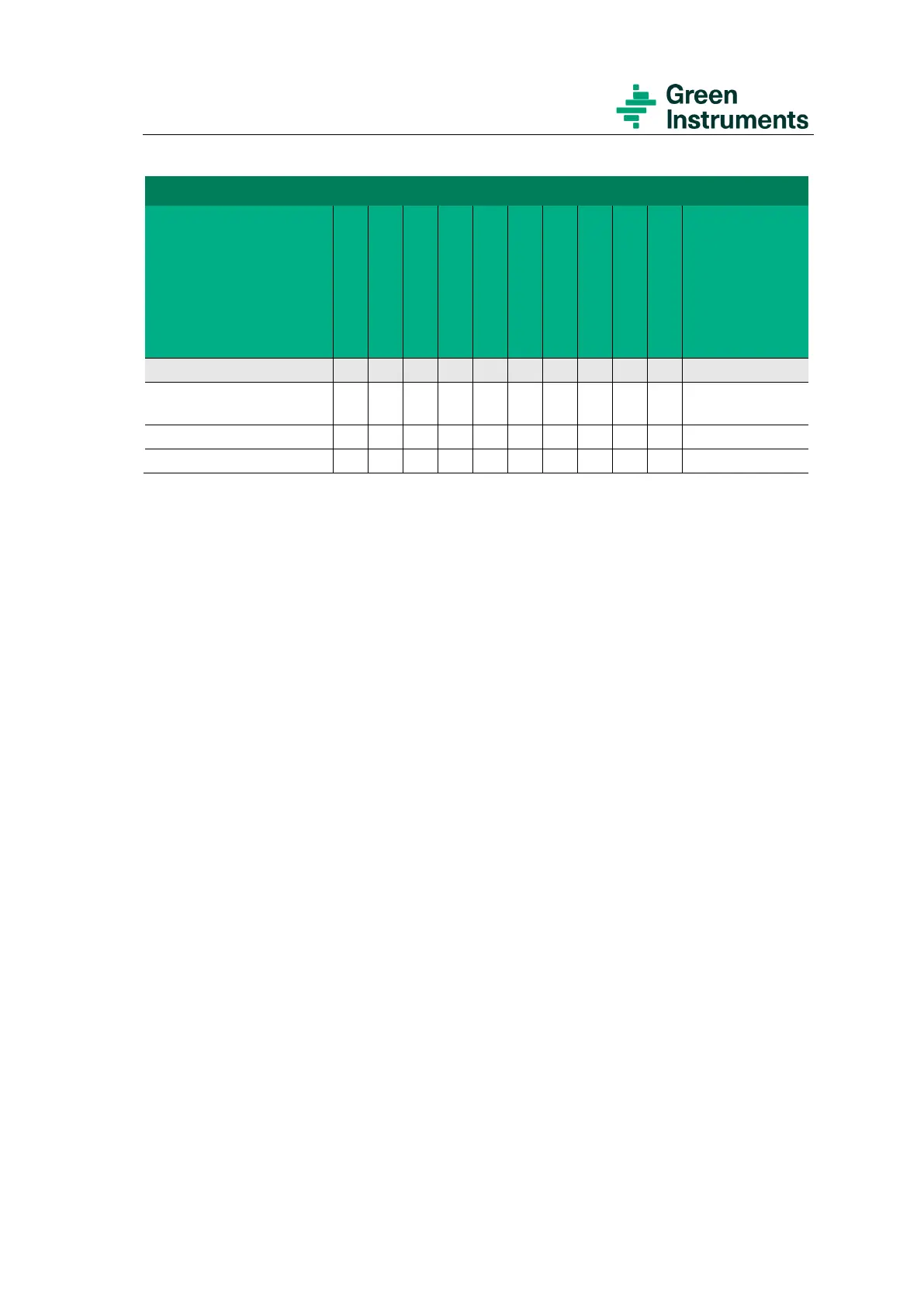

Figure 8-1: Planned Maintenance Program for the Water Monitoring System

8.1 Inspection & Cleaning

8.1.1 General Notes

In general as a routine maintenance, please make sure that the sensors and measuring

chambers are clean. Please follow the planned maintenance program in Figure 8-1. We

recommend a visual inspection every week.

If the sensor measurement is static, seems unrealistic, or the response time is slow, cleaning

of sensor and measuring chamber could be necessary

Another important routine maintenance is the validation of the sensors. Please follow the

planned maintenance program in Figure 8-1.

The strainer must be inspected and cleaned. We recommend checking the strainer every

week or more frequently. Make sure to integrate strainer check in the routine maintenance

schedule according to achieved experience during operation.

8.1.2 WM

PAH

When inspecting the G6110/G6111 PAH chamber or G6110 bushing, it is important to

check internal surfaces to verify that these are clean. Furthermore, pay close attention to

the lenses which should be totally clean from oil and salt deposits. In order to clean and

flush away solids manually, please attach the syringe to the CAL. INPUT of VALVE 4 and

use the syringe to suck out any remaining water inside the measuring chamber. Clean

Loading...

Loading...