Model G0771Z (Mfd. Since 01/21)

-47-

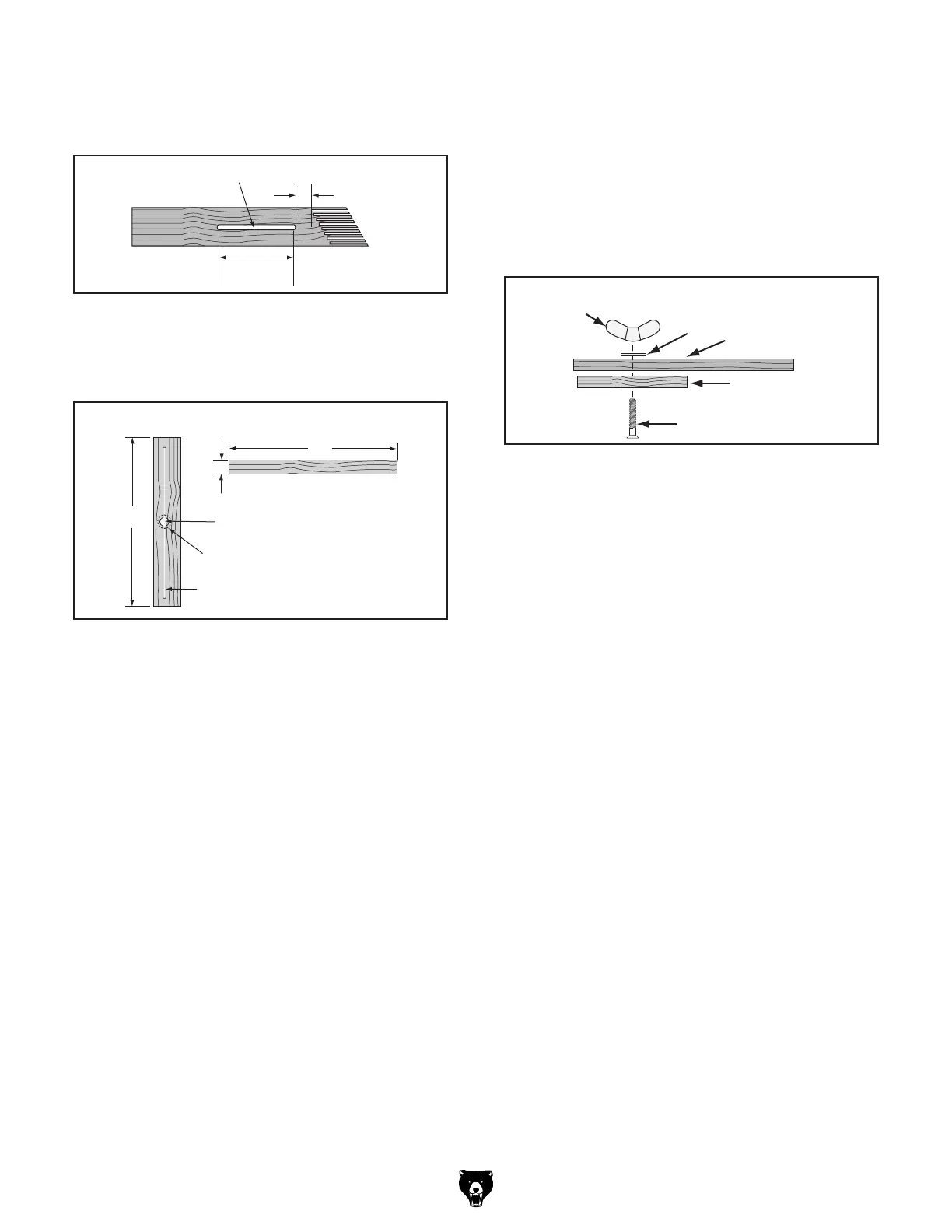

5"

5"

4" Slot

(Top View)

(Side View)

3

/

8

"

Countersink on Bottom

1

/

4

" Hole

Figure 75. Miter bar pattern.

5. Cut a miter bar approximately 5" long that will

fit in table miter slot, as shown in Figure 75.

7. Mark a 4" line through center of countersunk

hole in center, then use a jig saw with a nar-

row blade to cut it out.

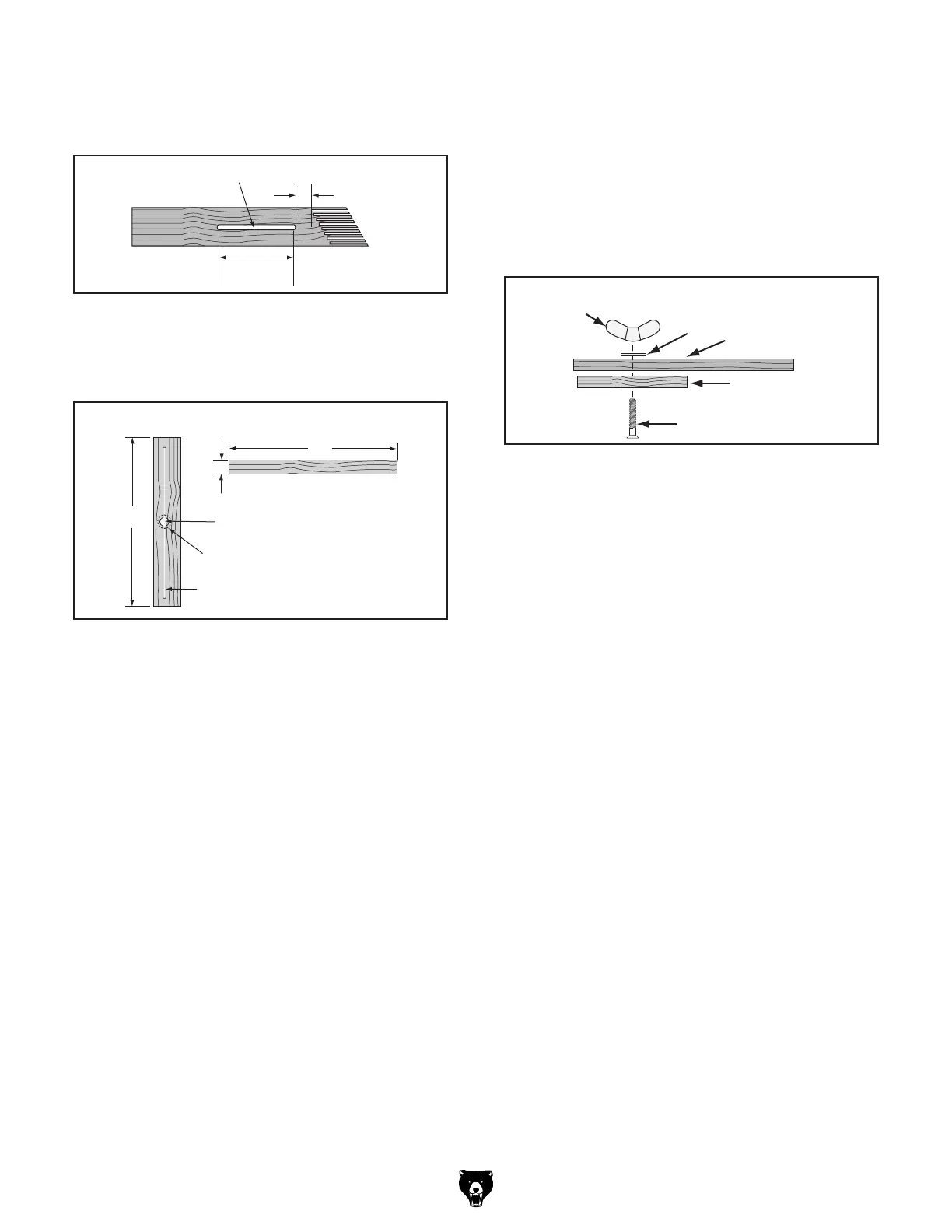

8. Assemble miter bar and featherboard with

a

1

⁄4"-20 x flat head screw, flat washer, and

a wing nut or a star knob (see Figure 76).

Congratulations! Your featherboard is com-

plete.

4. Rout a

1

⁄4"–

3

⁄8" wide slot 4"–5" long in

workpiece and 1"–2" from short end of feath-

erboard (see Figure 74).

Figure 74. Slot routed in featherboard.

1"-2"

4"-5"

1

/

4

"-

3

/

8

" Slot

(Side View)

Wing Nut

Miter Bar

Featherboard

Flat Head Screw

Flat Washer

Figure 76. Assembling miter slot featherboard

components.

Note: The routed slot, countersink hole, and

flat head screw are essential for miter bar to

clamp into miter slot. When wing nut is tight-

ened, it will draw flat head screw upward into

countersunk hole. This will spread sides of

miter bar and force them into walls of miter

slot, locking featherboard in place.

Tip: The length of the flat head screw depends

on thickness of featherboard—though 1

1

⁄2" to

2" lengths usually work.

Now, proceed to Mounting Featherboard in

Miter Slot on Page 48.

6. Drill a

1

⁄4" hole in center of bar, then counter-

sink bottom to fit a

1

⁄4"-20 flat head screw.

Tip: Consider making miter bar longer for

larger featherboards—approximately half the

length of total featherboard—to support force

applied to the featherboard during use.

Loading...

Loading...