-60-

Model G0771Z (Mfd. Since 01/21)

Blade Tilt Calibration

The blade tilt settings for this saw have been set at

the factory and should not require adjustment dur-

ing assembly. However, after prolonged use, or if

the saw does not cut accurate bevels, the settings

should be checked and adjusted accordingly.

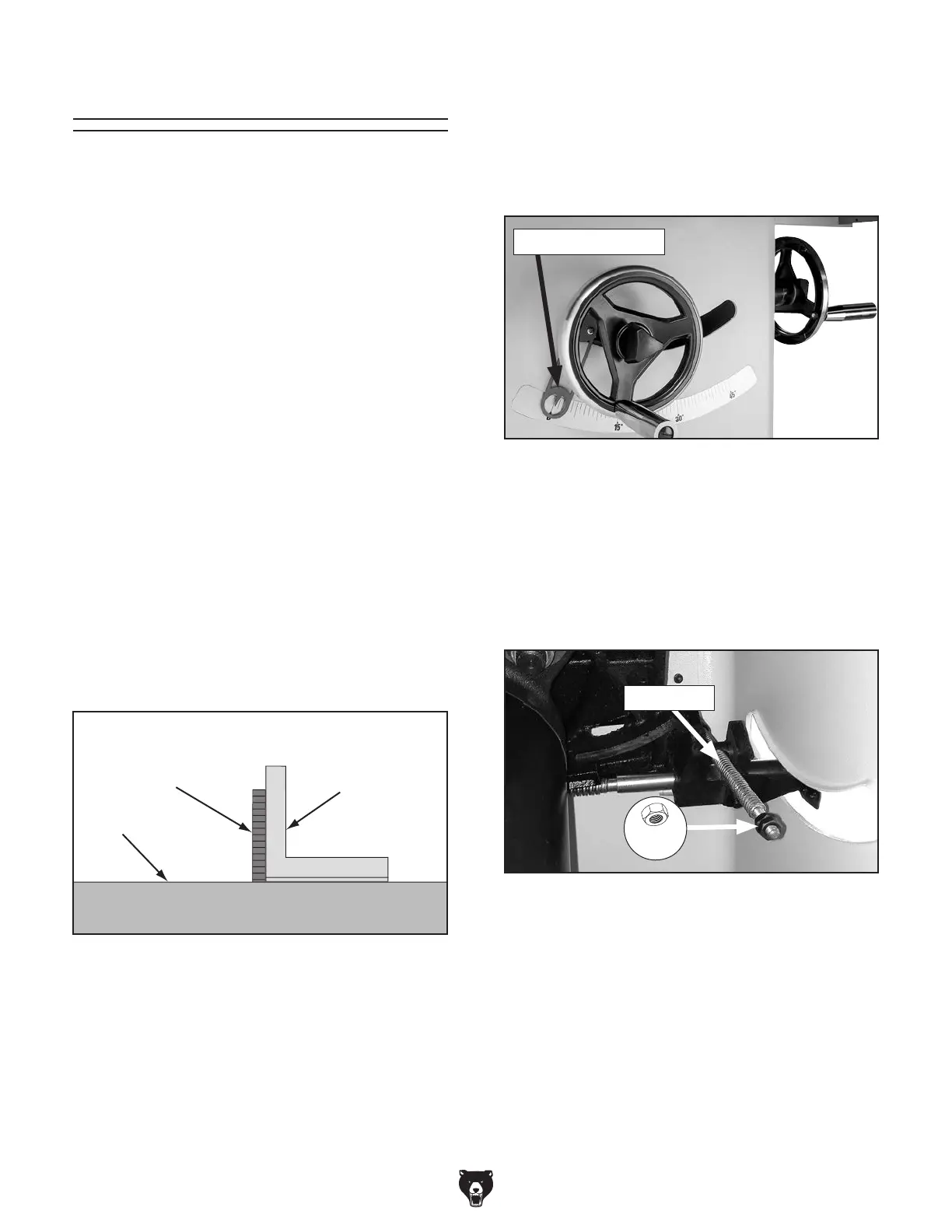

Note: The tilt scale reads "0" when the blade is

90° to the table.

Tools Needed Qty

90° Square ........................................................ 1

45° Square ........................................................ 1

Hex Wrench 4mm .............................................. 1

Setting 90° Stop

1. DISCONNECT SAW FROM POWER!

2. Raise blade as high as it will go, then tilt it

toward 90° until it stops and cannot be tilted

any more.

3. Place a 90° square against table and blade

so it contacts blade evenly from bottom to

top, as shown in Figure 104. Make sure a

blade tooth does not obstruct placement of

square.

Figure 104. Checking blade at 90°.

Table

90° Square

Blade

— If blade is 90° to table, then no adjust-

ments are necessary. Make sure tilt indi-

cator arrow shown in Figure 105 points to

0° mark on scale. Adjust position by loos-

ening Phillips head screws, moving indica-

tor with fingers, then tightening screws.

— If blade is not 90° to table, you will need to

adjust 90° stop nuts. Proceed to Step 4.

4. Remove motor cover (see Page 20).

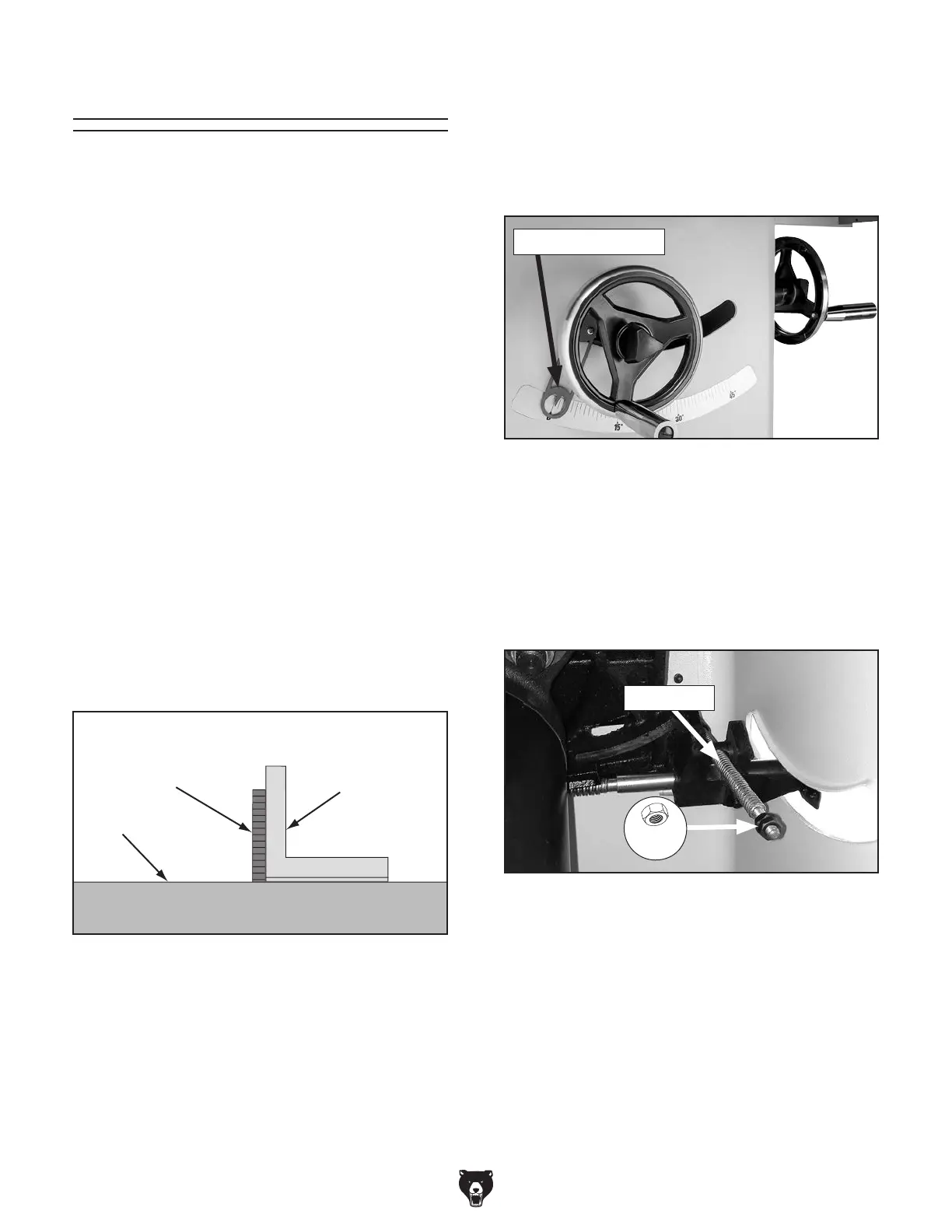

5. Loosen (2) M8-1.25 hex nuts on leadscrew

(see Figure 106).

Figure 106. Location of 90° stop nuts.

Leadscrew

6. Tilt blade to about 5° so there is room for stop

nuts to move.

7. Loosen stop nuts and adjust according to

how far off blade was from 90°. Recheck

blade and repeat adjustment as necessary

until blade stops at 90°, then tighten stop nuts

against each other and replace motor cover.

Note: Rotating stop nuts clockwise adjusts

blade further to right; rotating them counter-

clockwise adjusts blade to left.

x 2

Figure 105. Tilt indicator arrow.

Tilt Indicator Arrow

Loading...

Loading...