35

Installation

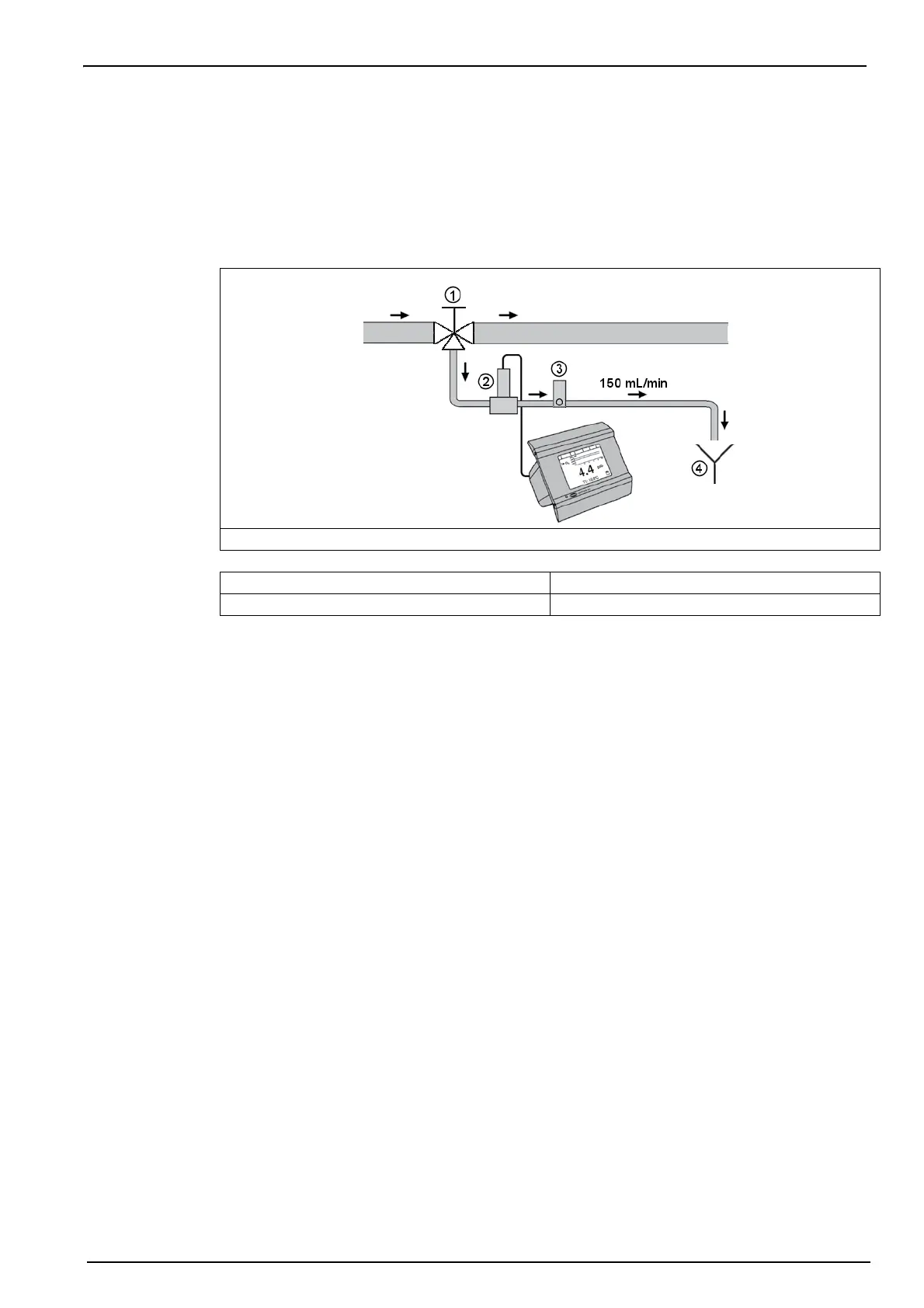

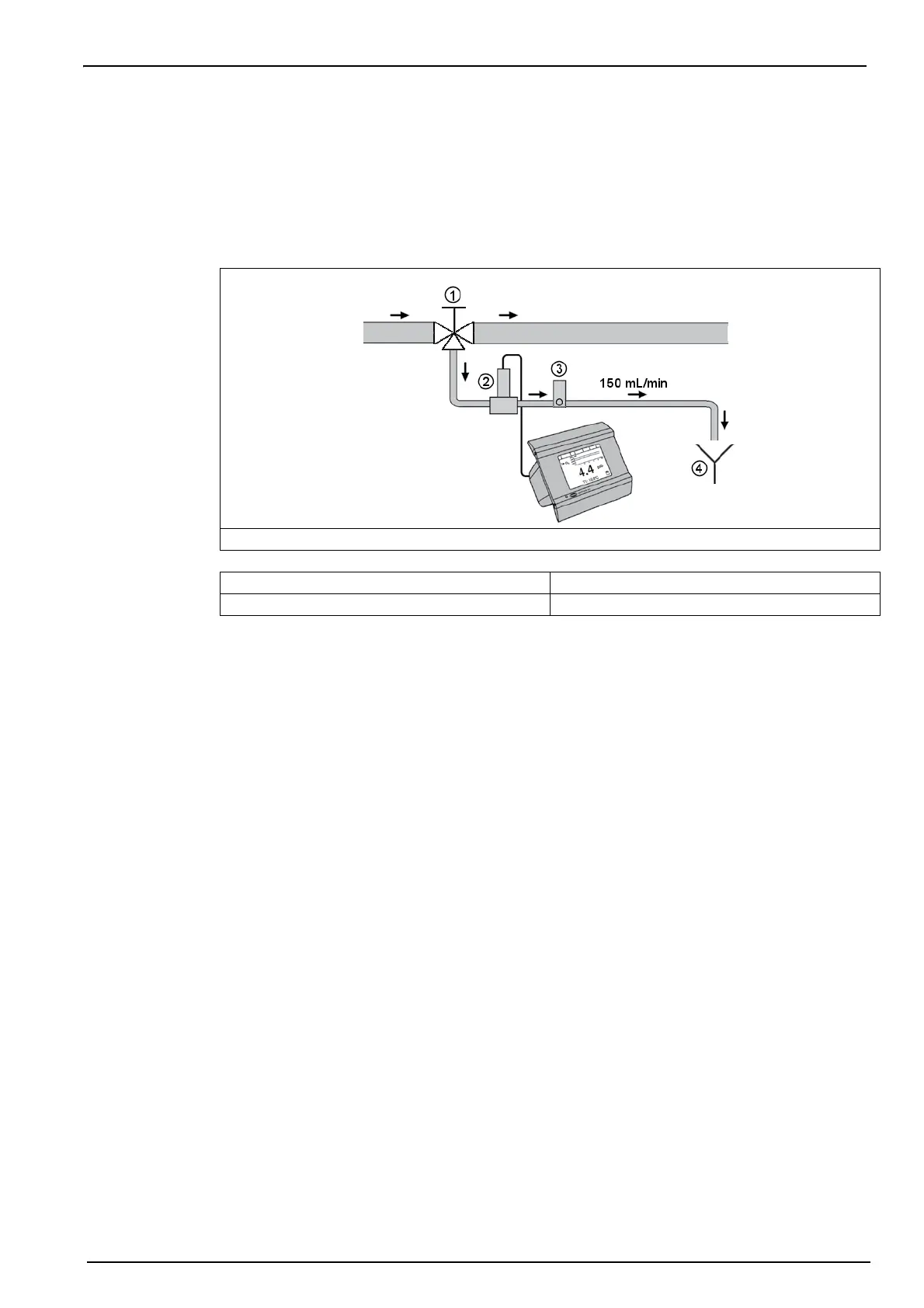

3.8.3 Recommended sample flow rate

For optimal response time, the recommended sample flow rate for optical sensors is

150 mL/min. The optimal TC sensor flow rate is based on the membrane and is necessary a

higher flow rate for TC sensors.

Control the flow with the outlet valve on the flow meter (number 3 in Figure 18 below) to avoid

foam developing inside the flow chamber which could lead to erroneous oxygen measurement

values.

3.8.4 Sensor insertion

• Insert the sensor straight into the flow chamber or socket. Do not twist the sensor.

• Hand tighten the attaching collar.

• Connect the sensor cable.

Check for leaks; replace O-rings if product leaks are visible.

3.8.5 Sensor removal

• If not using the ORBISPHERE 32003 insertion/extraction valve (refer to The 32003

insertion/extraction valve on page 37) you will need to shut off the sample flow and drain the

sampling circuit of liquid.

• Remove the sensor cable connected at the sensor end.

• Hold the sensor body in one hand to avoid rotation, and unscrew the collar with the other

hand.

• Pull the sensor straight out of the socket or flow chamber.

• Install sensor storage cap and sensor base (to protect the connection).

Figure 18 Typical measurement schematic

1. Valve to redirect sample for measurement 3. Flow meter with outlet valve

2. Sensor and flow chamber combination 4. Drain

Loading...

Loading...