36

Installation

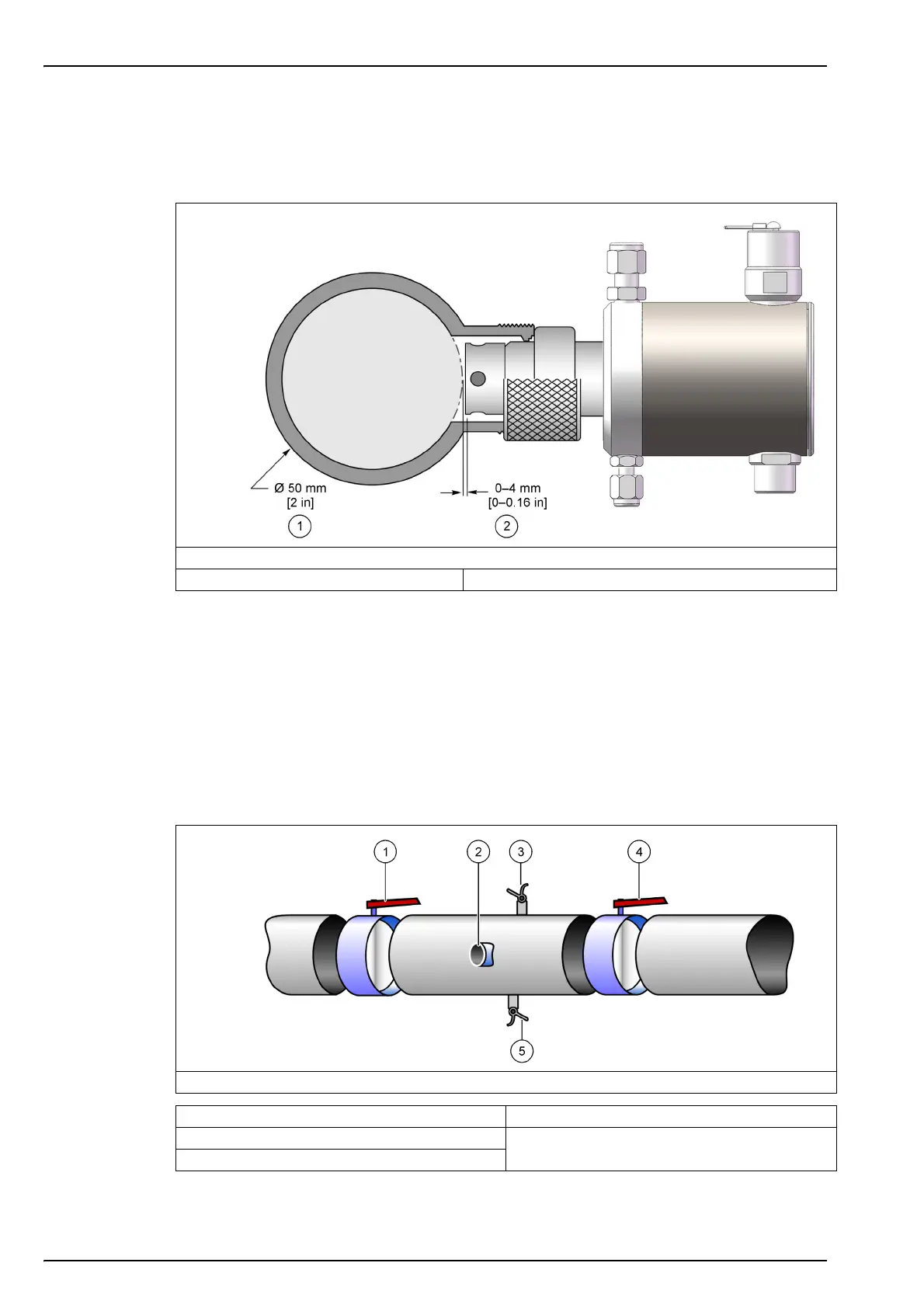

3.8.6 Weld-on stainless steel socket

The ORBISPHERE 29501 weld-on sensor socket can be used to install a sensor into a stainless

steel pipe (min.Ø 50 mm or 2”). When welding the socket to the pipe, check that setback

between the pipe’s inner diameter and the sensor tip does not exceed 4 mm (see diagram).

Note: Be sure to remove the two O-rings from the socket before welding and leave the sensor’s stainless

steel cap screwed on during welding to prevent thread distortion.

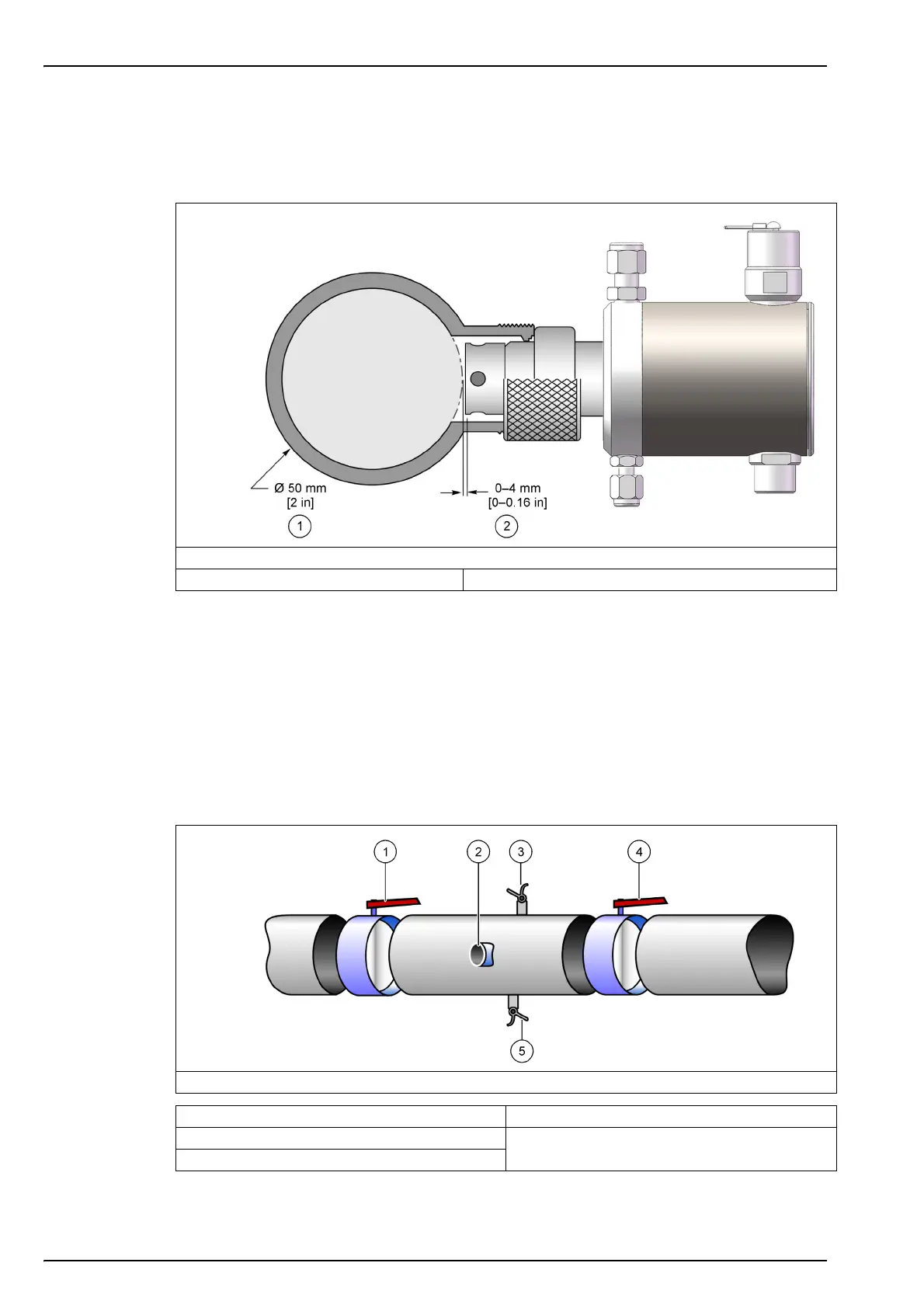

Recommendation:

To facilitate sensor removal and installation, we suggest installing the socket in a location where

the liquid can be drained quickly and easily. By creating a one meter long piece of pipe

(Figure 20) with shut off valves at both ends, just a small volume of liquid needs to be drained to

enable sensor removal.

Also, a precise sensor and socket installation can be performed in the workshop, and this

assembly can be placed in the production line with minimal down time.

Figure 19 Weld-on sensor socket

1. Pipe external diameter 2. Setback allowed from internal pipe diameter

Figure 20 Installation in-line

1. Shut off valve 4. Shut off valve

2. Sensor socket 5. Sampling valve

3. Sampling valve

Loading...

Loading...