Do you have a question about the Hach SIGMA 900 and is the answer not in the manual?

Explains signal words (Danger, Caution, Note) for hazard communication.

Details warning symbols and their meanings for safe operation.

Defines confined space and its hazardous conditions.

Covers dimensions, weight, and cabinet details.

Details pump, sensor, volume, and repeatability specs.

Lists sampling modes and interval settings.

Describes user interface, clock, programming features, language, and manual modes.

Details program storage, cascade, and data logging features.

Lists power requirements, operating ranges, cooling, and temperature specs.

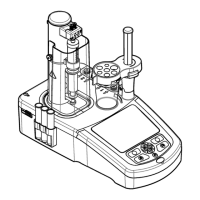

Provides an overview of the sampler's design and capabilities.

Explains how the liquid sensor enables accurate sample volumes.

Explains intake tube pre-rinsing and sample retry features.

Guidelines for choosing location and mounting the sampler.

Details steps for physically installing the sampler unit.

Explains how to install the pump tube correctly.

Details how to connect the vinyl intake tubing.

Explains the assembly process for Teflon tubing.

Guides on properly setting up the intake line and strainer.

Instructions for installing sample bottles and retainers.

Provides instructions and safety precautions for power connections.

Details connecting to flow meters via contact closure and pulse inputs.

Describes connecting to flow meters using 4-20 mA signals.

Explains the auxiliary receptacle for I/O signals.

Details how to use the 12V DC connection for power.

Explains the auxiliary connector and its pin assignments.

Describes the splitter interface for multiple connections.

Instructions for cleaning refrigerator, cabinet, and bottles.

Procedure for cleaning intake and pump tubing.

Covers maintenance related to pump tubing.

Factors affecting pump tubing life and estimates.

Step-by-step guide for replacing pump tubing.

Explains humidity indicator and desiccant replacement.

How to calibrate the temperature control system.

Instructions for replacing fuses.

Steps to reset the internal circuit breaker.

Explains the keypad layout and function of each key.

Provides helpful tips for programming the sampler.

How to change the instrument's display language.

Guides on initial setup and parameter entry.

Steps to enter parameter entry mode.

Lists and explains various system messages shown on the display.

Continues listing and explaining system messages.

Continues listing and explaining system messages.

Continues listing and explaining system messages.

Procedure for setting the sampler's internal clock and date.

How to create, save, and retrieve multiple programs.

Explains how the sampler logs sample data.

Guides on manual operation of pump and distributor arm.

Explains sampling triggered by external conditions.

How to program sampling based on liquid levels.

Overview of storm water sampling capabilities.

Detailed steps for storm water programming.

Explains special output signals and their modes.

Steps to program special output functions.

Explains messages related to special outputs.

Introduces advanced programming features.

Covers start/stop, intervals, and bottle configurations.

Explains timed bottle modes and pre-advance functionality.

Details flow proportional setup and calculation methods for pulses.

Calculating intervals using external pulses.

Calculating intervals using 4-20mA signals.

Continues calculation examples for 4-20mA signals.

Continues calculation examples for 4-20mA signals.

Worksheet for configuring the main sampler program.

Continuation of the main sampler program worksheet.

Worksheet for calibrating sample volume.

Worksheet for setting up storm water programming.

Checklist for storm water setup verification.

Final checklist before leaving the installation.

Diagnosing and resolving issues with the liquid sensor.

Flowchart for diagnosing and resolving sampler issues.

Continuation of the troubleshooting flowchart.

Overview of instrument programming steps and special functions.

Visual guide for setting up various sampling programs.

Visual guide for setting up various sampling programs.

Visual guide for level control and first flush sampling.

Exploded view and parts list for assembly 1.

Exploded view and parts list for assembly 2.

Exploded view and parts list for assembly 3.

Exploded view and parts list for assembly 4.

Exploded view and parts list for assembly 5.

Exploded view and parts list for assembly 6.

Wiring diagram and components for assembly 7.

Exploded view and parts list for assembly 8.

Exploded view and parts list for assembly 9.

Exploded view and parts list for assembly 10.

Exploded view and parts list for assembly 11.

Exploded view and parts list for assembly 12.

Exploded view and parts list for assembly 13.

Exploded view and parts list for assembly 14.

Exploded view and parts list for assembly 15.

| Type | Portable Sampler |

|---|---|

| Power | 12 VDC |

| Controller | Microprocessor-based |

| Pump Type | Peristaltic |

| Operating Temperature | 0 to 50 °C (32 to 122 °F) |

| Communication | RS-232 |

| Storage Capacity | 24 bottles |