Page 60

Final Check List

8837prgwrk.fm

Section 6

6.5 Final Check List

For Storm Water Setup

• Intake tubing must slope downward from the sampler to the source—no

loops or dips.

• Does the pump create a lift? If not:

• Did you secure the anchor strainer to prevent the flow velocity from

lifting the strainer to the water surface and exposing it to air?

• Make sure the anchor strainer is submerged in channel.

• Check all intake and pump tubing connections, especially the Teflon

Connection Kit (Cat. No. 2186) for vacuum leaks at the connection

points.

• Did you calibrate the sample volume?

• When the starting conditions occur, will the anchor strainer be

submerged? (i.e. when starting on a level of 0.5 inches).

If this example was for a circular pipe, the anchor strainer would not be

submerged because the Teflon/Stainless Steel anchor strainer is

0.84 inches in diameter.

Note: A shallow depth, 0.406 in. diameter anchor strainer (Cat. No. 2071) is

available for low flow applications.

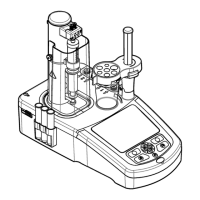

• Does the distributor deposit samples in the bottle?

• Press the

Start Program key; this will cause the distributor to seek

bottle #1.

• Press the

Change/Halt key.

• With the program halted, press the

Take Sample key.

• Press the

Bottle Advance key.

• Press the

Take Sample key again.

• Remove the controller from the bottle tray. Are samples in bottle #1

and #2?

• If the sampler is being powered by a battery, is the battery fully charged?

• Are the knobs on the liquid sensor and pump cover hand tight?

• Make sure the sampler is level.

• Before leaving, make sure the display reads

PROGRAM RUNNING.

Loading...

Loading...