9

T40

HBMA24633.0en/de

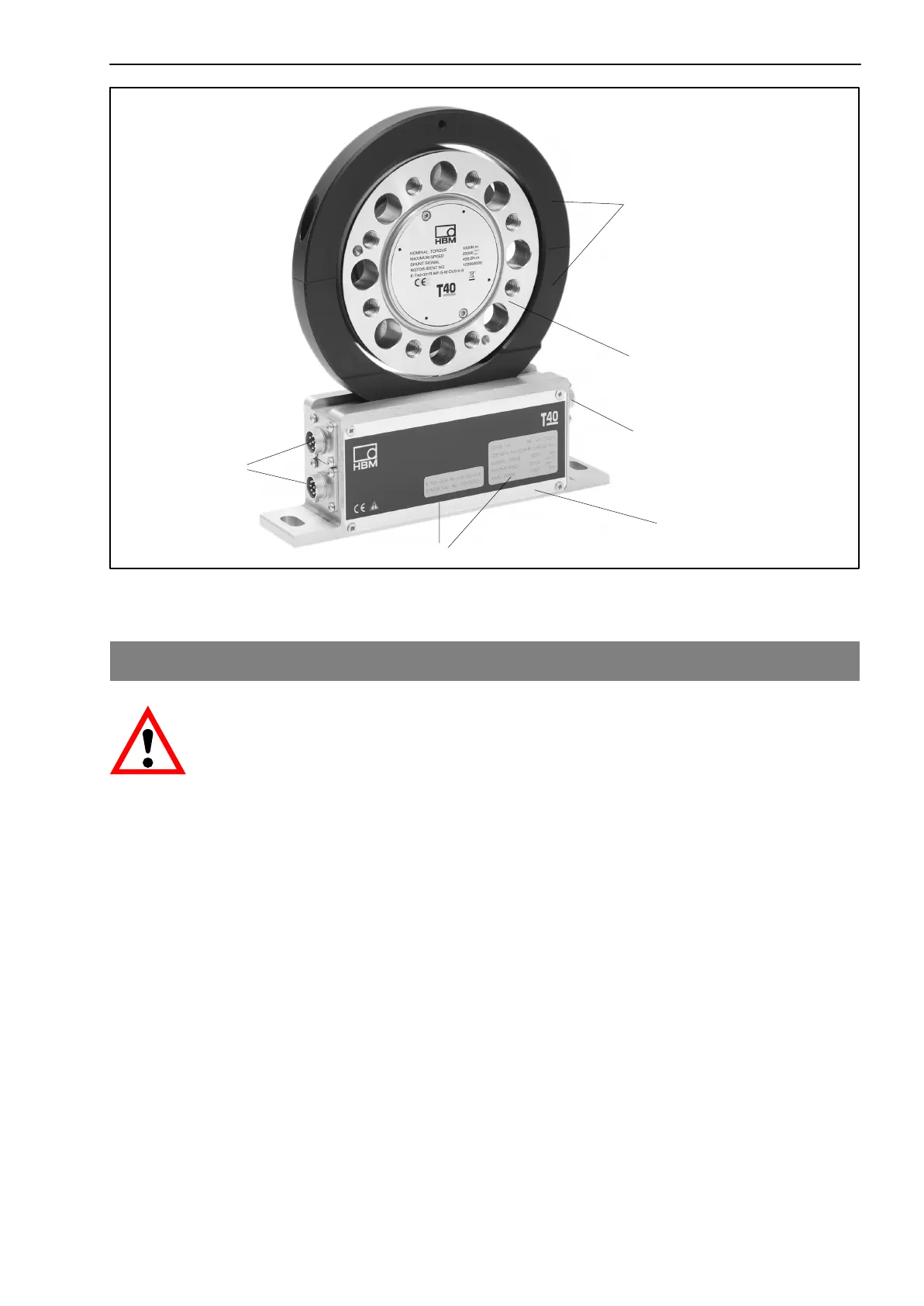

Stator housing

Rotor

Antenna segments

Type plate

Connector plugs

Connector plug

Fig.2.1: Mechanical construction

3 Mechanical installation

WARNING

Handle the torque flange carefully. The transd ucer might suffer

permanent damage from mechanical shock (dropping), chemical effects

(e.g. acids, solvents) or thermal effects (hot air, steam).

With alternating loads, you should cement the rotor connectionscrews

into the mating thread with a screw locking d evice (medium strength) to

exclude prestressing loss due to screw slackening.

An appropriate shaft flange enables the T40 torque flange to be mounted

directly. It is also possible to mount a joint shaft or relevant compensating

element directly on the rotor (using an intermediate flange when required).

Under no circumstances must the permissible limits specified for bending

moments, lateral and longitudinal forces be exceeded. Due to the T40

measurement flange’s high torsional stiffness, dynamic shaft train changes

are kept to a minimum.

Loading...

Loading...