36

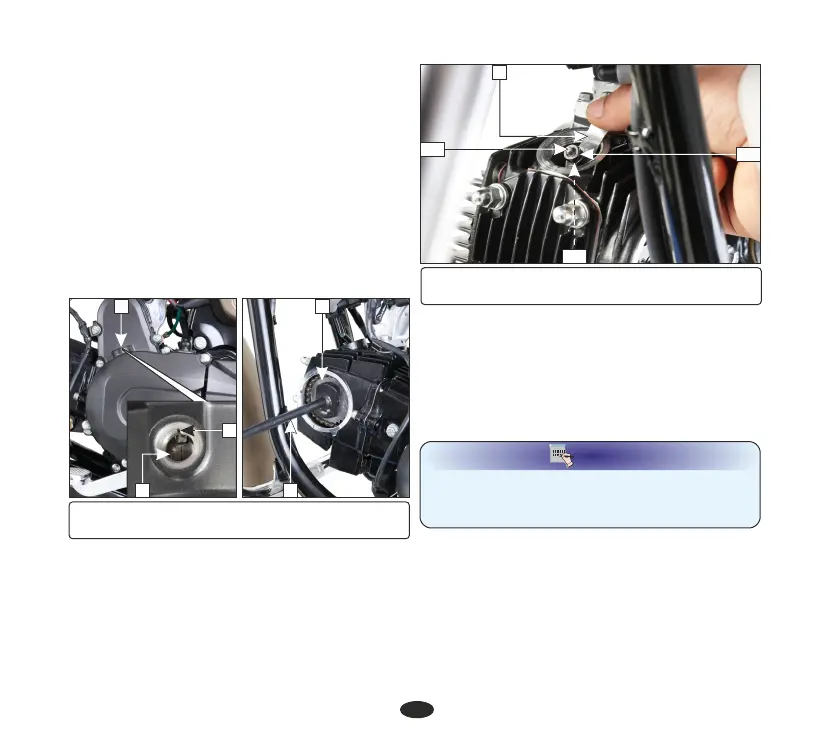

(4) Timing hole cap (5) 'T' mark (6) Index mark

(7) Cam sprocket (8) Special tool

4

6

7

8

on the left crankcase cover. In this position

the piston will either be on the compression

or exhaust stroke. The adjustment must be

made when the piston is at Top Dead

Center and both the inlet and exhaust valves

are closed. This condition can be

determined by moving the rocker arms. If

they are free, it is an indication that the

valves are closed and the piston is in

compression stroke. If they are tight, the

valves are open, rotate the cam sprocket

O

(7) 360 clockwise and re-align the 'T'

mark with the index mark.

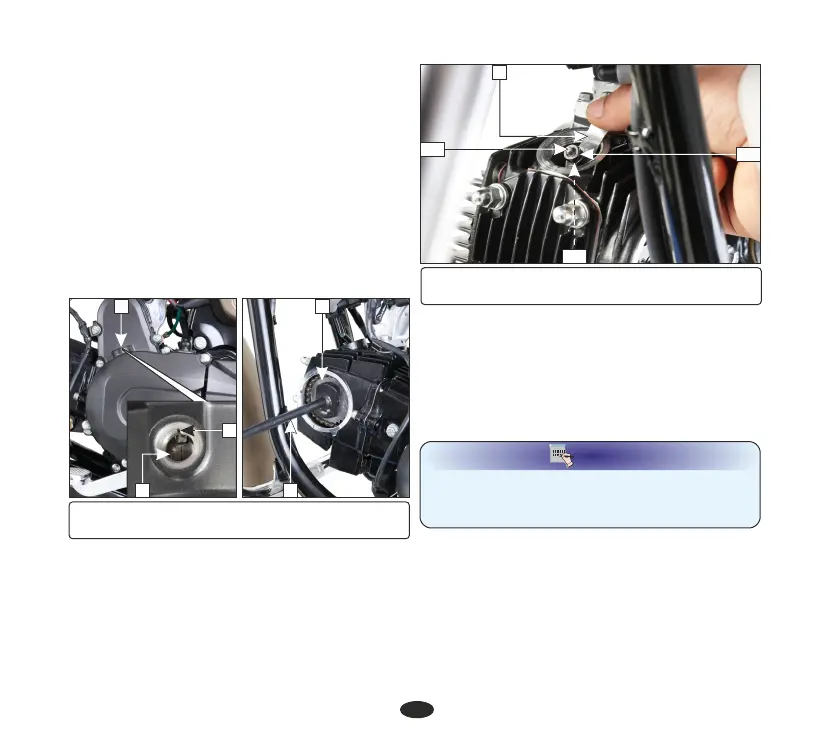

Standard clearance

Intake: 0.10 mm

• Check the clearance by inserting the feeler

gauge (9) between the adjusting screw

(10) and valve stem (11).

Exhaust: 0.10 mm

(9) Feeler gauge (10) Adjusting screw

(11) Valve stem (12) Lock nut

•

After tightening the lock nut, check again

the clearance.

•

Install all parts in the reverse order of

disassembly.

•

Adjust by loosening the lock nut (12) and

turning the adjusting screw until there is a

slight drag on the feeler gauge.

Before inserting the feeler gauge, smear a bit

of engine oil on the feeler gauge to avoid

damage to the feeler gauge.

NOTE

CLUTCH LEVER FREE PLAY

Adjustment

Clutch adjustment may be required if the

vehicle stalls when shifting into gear or tends

to creep or if the clutch slips, causing

acceleration to lag behind engine speed.

Normal clutch lever free play (1) is 10-20 mm

at the lever (2).

12

10

9

11

5

Loading...

Loading...