39

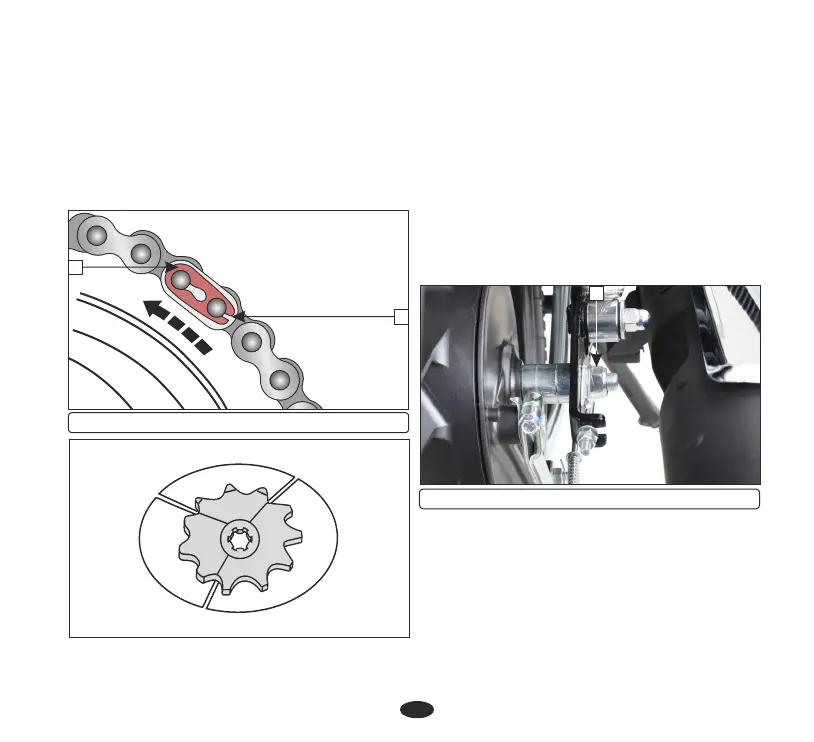

• Turn the chain to view chain lock plate (4)

inside the hole. Ensure that the chain lock

plate open end (5) is installed in the

opposite direction of the chain rotation.

If the chain is slack in one section and tight in

another, some links are kinked and binding.

Binding can be eliminated by frequent

lubrication.

4

5

(4) Chain lock plate (5) Open end

c

o

k

r

e

p

t

S

T

e

n

r

e

o

t

h

W

c

o

r

p

k

e

S

t

l

T

a

e

m

e

r

t

o

h

N

o

r

p

c

S

k

d

e

e

t

g

T

a

e

e

m

t

a

h

D

•

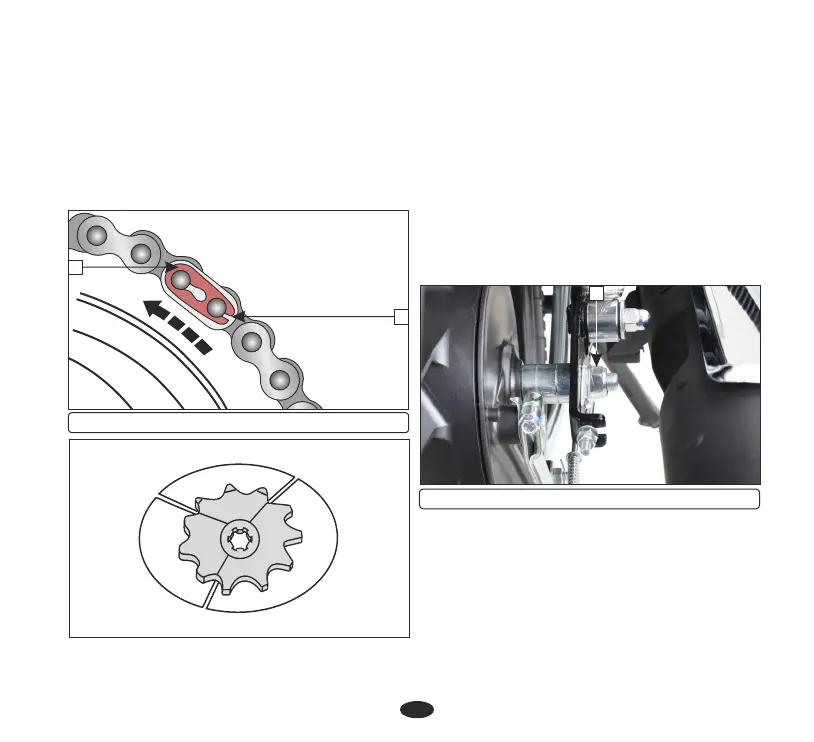

Inspect the sprocket teeth for wear or

damage.

(1) Rear axle nut

1

•

Turn both the adjusting nuts (4) in an equal

number of turns until the correct drive chain

slack is obtained. Turn the adjusting nut

clockwise to decrease the slack or

anticlockwise to increase the slack of the

chain.

•

Align the chain adjuster index mark (5) with

the corresponding scale graduations (6) on

both the sides of the swing arm equally.

•

Park the vehicle on its main stand with the

transmission in neutral and the ignition

switch in "OFF" position.

Adjustment

•

Loosen the rear axle nut (1) and sleeve nut

(2). Loosen both the drive chain lock nuts

(3).

•

If the drive chain or sprockets are

excessively worn or damaged, they should

be replaced. Never use a new chain with

worn out sprockets since this will result in

rapid chain wear.

Loading...

Loading...