Ecodome User Manual ii

Figure 6-4. Push the dichroic toward the large retaining tab to free it from the

wheel tabs. ..................................................................................................... 6-6

Figure 6-5. You can easily tell which side of a dichroic is coated by placing a pen

or other object near the surface; on the coated side, the reflection from the

object will appear to touch the object. ........................................................... 6-6

Figure 6-6. The rotating litho wheel and rotating effects wheel have built-in

plastic tabs that hold the spring in place. ...................................................... 6-7

Figure 6-7. To replace a static litho in the rotating litho wheel, gently separate

the wheel and reach behind the wheel to push the litho out. ........................ 6-8

Figure 6-8. Location of the retaining tabs and slot that secure the static litho in

the rotating litho wheel. ................................................................................ 6-9

Figure 6-9. The gap between the two halves of the rotating litho wheel must be uniform.

6-9

Figure 6-10. An aperture ring, if required, must be placed on top of the litho/

effect and under the spring. ........................................................................ 6-10

Figure 6-11. When you replace a rotating litho or rotating effect, make sure the

tip of the spring is fully seated under the wheel tabs; it cannot protrude from

under the tabs.............................................................................................. 6-10

Figure 6-12. Replacing a custom multi-colored litho in the metal holder.. 6-11

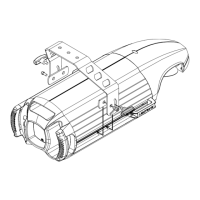

Figure 6-13. Loosening the lamp assembly screws gives you access to the

fixture lamp. ................................................................................................ 6-12

Figure 6-14. Removing the lamp assembly from the fixture. ..................... 6-12

Figure 6-15. Pull straight up on the lamp, grasping its ceramic base, to remove

it from the assembly.................................................................................... 6-13

Figure 6-16. Hold the lamp by its ceramic base and gently press the two base

pins into the socket. .................................................................................... 6-13

Figure 6-17. You can look at the lamp label text to make sure the lamp plate is

oriented correctly; incorrect orientation can result in damage to the fixture and

the lamp. .................................................................................................. 6-14

Figure 6-18. Lamp optimization screws...................................................... 6-15

Figure 6-19. Opening the fixture’s access door. ......................................... 6-16

Figure 6-20. Location of the anti-reflective glass, lenses and hot mirror... 6-17

Figure 6-21. The lens tube contains the zoom lenses. ............................... 6-17

Figure 6-22. Clean both sides of the hot mirror glass. ............................... 6-18

Figure 6-23. The ideal position of the laser is no more than 2” (5 cm) directly

above the center of a perfectly round light beam. ...................................... 6-19

Figure 6-24. High-voltage component location........................................... 6-20

Figure 6-25. Orient the fixture directly facing a wall no less than 10 ft. (3 m) away.

6-21

Figure 6-26. Locating the center point of the projected light beam. The laser

should be no more than 2” (5 cm) above the center.................................... 6-24

Figure 6-27. The laser aiming device assembly has three screws that can be

used to adjust the position of the laser....................................................... 6-25

Figure B-1. Factory configuration of the Technobeam rotating litho wheel. . B-1

Figure B-2. Factory configuration of the Technobeam color wheel. .............. B-2

Figure B-3. Factory configuration of the Technobeam rotating effects wheel. B-

Loading...

Loading...