--- 53 ---

11-3. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

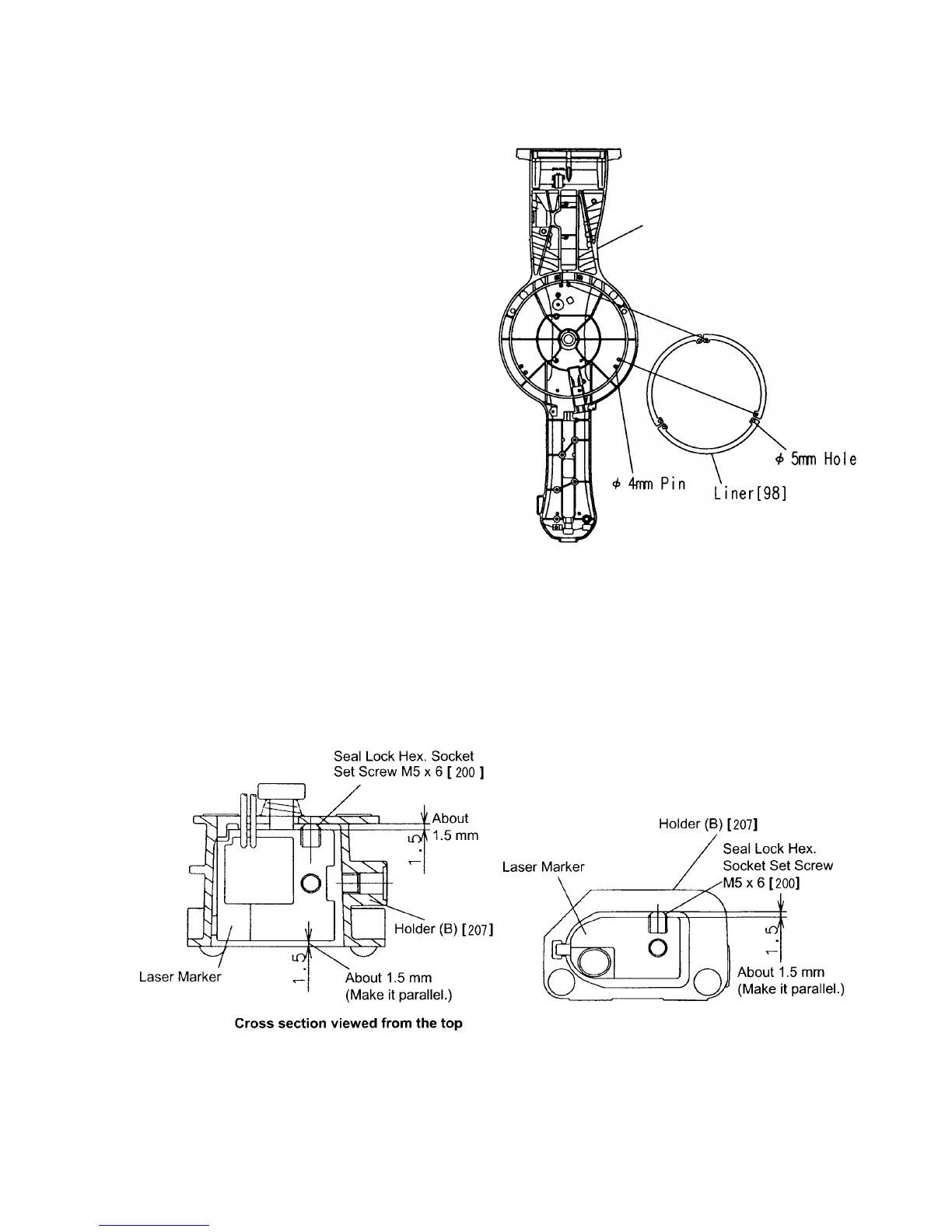

(4) When replacing the Laser Marker [198A], screw the two Seal Lock Hex. Socket Set Screws M5 x 6 [200] into

the Laser Marker [198A]. To adjust the accuracy of the Laser Marker [198A] easily, protrude the tips of the

two Seal Lock Hex. Socket Set Screws M5 x 6 [200] about 1.5 mm from the Laser Marker [198A] using the

2.5-mm hex. bar wrench so that Holder (B) [207] and the Laser Marker [198A] become almost parallel as

shown in Fig. 66-a and Fig. 66-b. Refer to "11-10. Adjustment of Laser Marker Accuracy" for adjustment of the

laser marker accuracy.

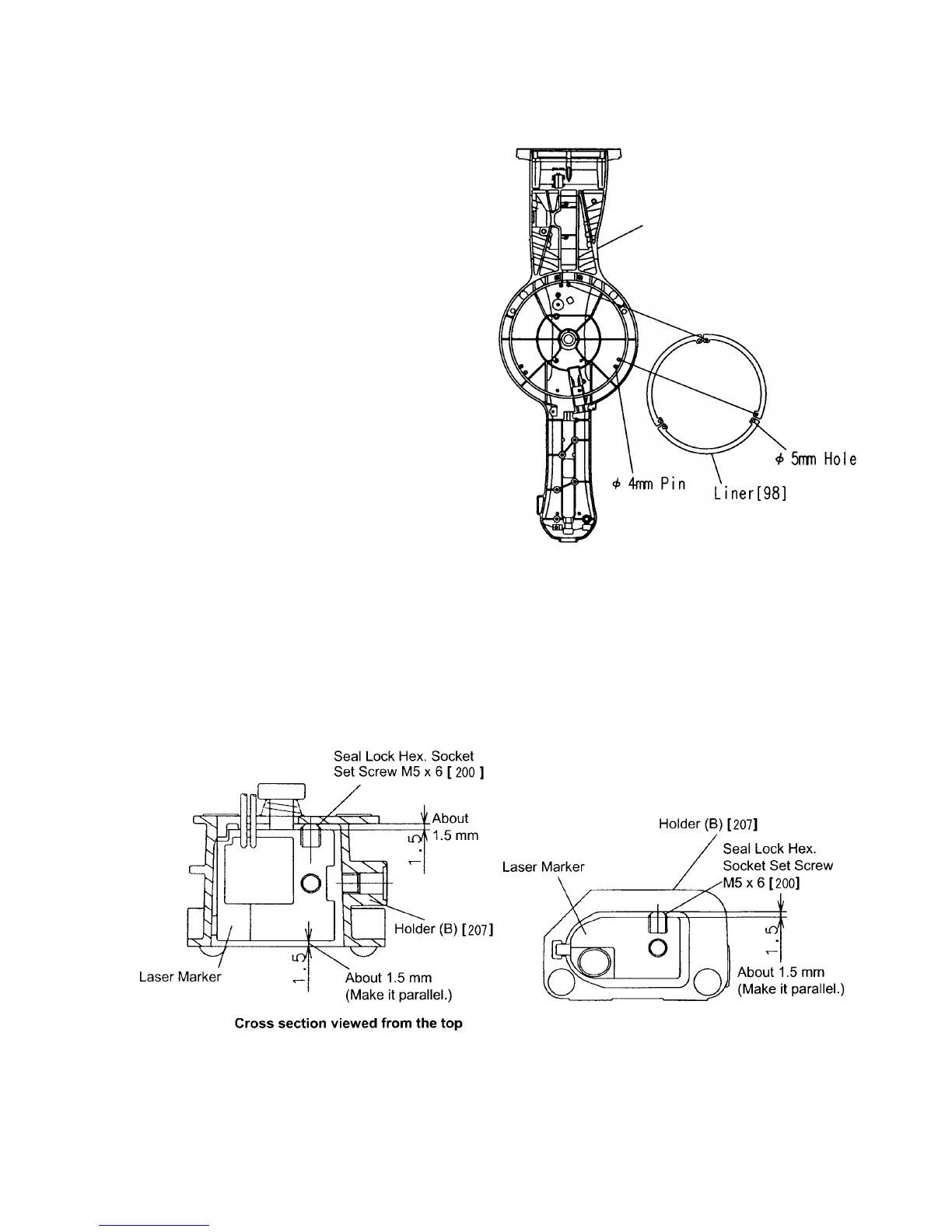

Fig. 65

Back of the turn table

Fig. 66-a

(1) Prior to reassembly, measure the insulation

resistance of the armature, stator, switch and

other electrical components and confirm that the

insulation resistance of each part is more than

5 M Ω.

(2) When replacing the Spring [152], apply 3 grams

of Hitachi Motor Grease to the inner

circumference of the new spring prior to

assembly.

(3) When replacing or reassembling the Liner [98],

ensure it is positioned and assembled as

illustrated in Fig. 65. In addition, coat 10 grams

of Hitachi Motor Grease on the liner sliding

portion of the Turn Table [26].

Fig. 66-b

Cross section viewed from the front

[198A]

[198A]

Loading...

Loading...