OM-925 Page 36

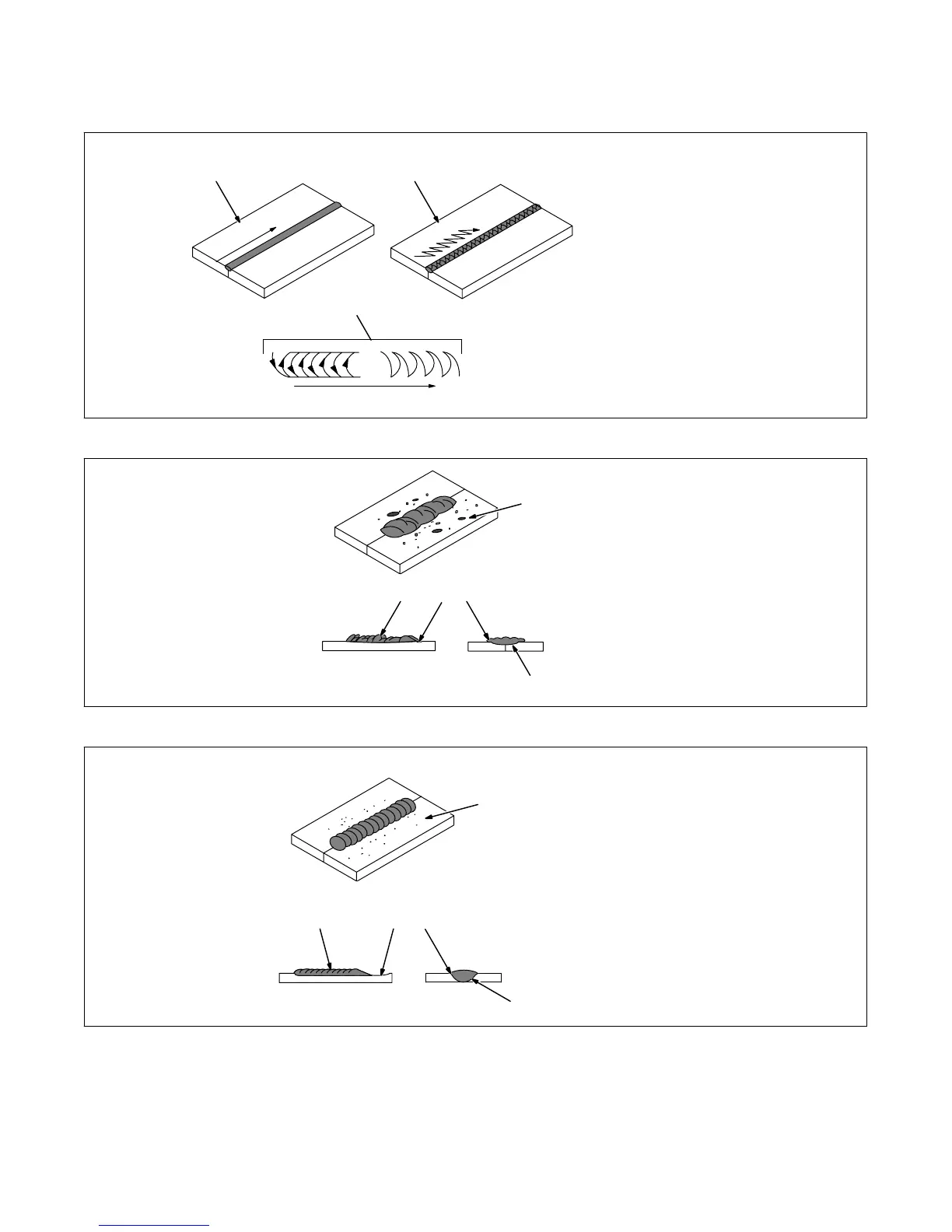

9-5. Gun Movement During Welding

. Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps,

a weave bead or multiple stringer beads works better.

1 Stringer Bead − Steady

Movement Along Seam

2 Weave Bead − Side To Side

Movement Along Seam

3 Weave Patterns

Use weave patterns to cover a wide

area in one pass of the electrode.

S-0054-A

3

1 2

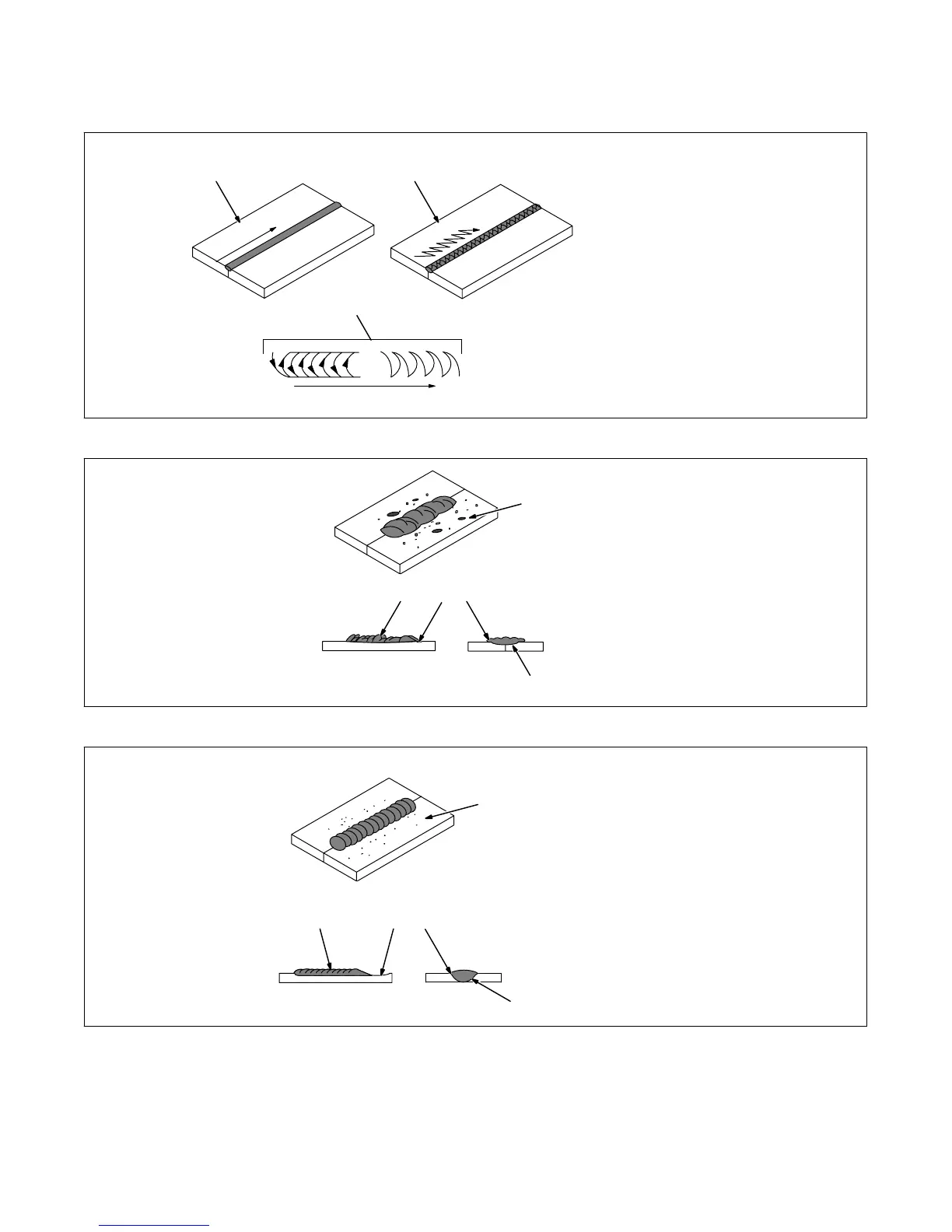

9-6. Poor Weld Bead Characteristics

1 Large Spatter Deposits

2 Rough, Uneven Bead

3 Slight Crater During Welding

4 Bad Overlap

5 Poor Penetration

5

4

2

3

1

S-0053-A

9-7. Good Weld Bead Characteristics

1 Fine Spatter

2 Uniform Bead

3 Moderate Crater During

Welding

Weld a new bead or layer for each

1/8 in. (3.2 mm) thickness in metals

being welded.

4 No Overlap

5 Good Penetration into Base

Metal

S-0052-B

2

3

1

4

5

Loading...

Loading...